Introduction to Stainless Steel Wire Rope Slings

Stainless steel wire rope slings are flexible, robust, and corrosion-resistant lifting accessories made from multiple strands of stainless steel wires twisted together. They are available in various configurations, including single-leg slings, multi-leg slings, and bridle slings, to accommodate different lifting needs. The choice of a stainless steel wire rope sling depends on factors such as load capacity, sling length, environmental conditions, and the type of load being lifted.

Choosing the Right Stainless Steel Wire Rope Sling

Selecting the appropriate stainless steel wire rope sling is crucial for safe and efficient lifting operations. Here are the key factors to consider:

-

Load Capacity: Determine the weight of the load you need to lift. Stainless steel wire rope slings come with different load capacities, so choose one that exceeds the maximum weight of the load.

-

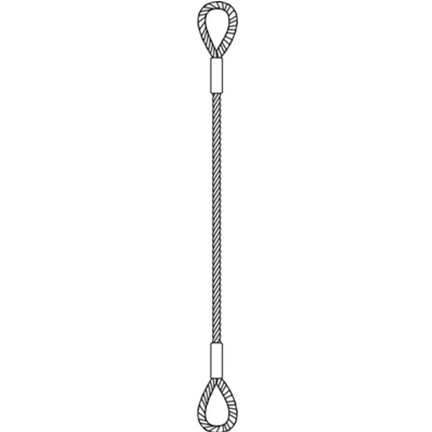

Sling Configuration: Decide on the sling configuration based on the lifting angle and load distribution. Single-leg slings are suitable for vertical lifts, while multi-leg and bridle slings are ideal for loads with multiple attachment points or uneven weight distribution.

-

Sling Diameter: The diameter of the wire rope sling affects its strength. Larger diameter ropes generally have higher load capacities. Ensure that the chosen diameter is compatible with your lifting equipment and load requirements.

-

Wire Rope Grade: Stainless steel wire ropes are available in various grades, with 304 and 316 being the most common. Grade 316 stainless steel is preferred for applications in corrosive environments, such as marine or chemical industries, due to its superior corrosion resistance.

-

End Fittings: Consider the type of end fittings or attachments needed for your specific application. Common end fittings include hooks, thimbles, and shackles. Ensure that the fittings are compatible with both the sling and the lifting equipment.

-

Sling Length: Determine the required sling length based on the distance between the lifting point and the load. Make sure to account for any additional height or reach needed to safely clear obstacles or obstructions during the lift.

-

Environmental Conditions: Consider the environmental factors that the stainless steel wire rope sling will be exposed to. If the sling will be used in a corrosive or saltwater environment, select a sling made from stainless steel with high resistance to corrosion.

-

Inspection and Maintenance: Ensure that the sling you choose complies with industry standards and regulations. Regularly inspect and maintain your stainless steel wire rope slings to identify signs of wear, damage, or degradation.

Using Stainless Steel Wire Rope Slings Safely

Proper usage of stainless steel wire rope slings is essential to ensure safety during lifting operations. Follow these guidelines:

-

Inspect Before Use: Before each use, thoroughly inspect the wire rope sling for signs of wear, damage, or corrosion. Pay close attention to wire breaks, kinks, and deformation.

-

Load Attachment: Attach the sling securely to the load, ensuring that the load is evenly distributed across the sling legs. Avoid side loading, which can reduce the sling's capacity and lead to failure.

-

Use Suitable Hardware: Select appropriate hooks, shackles, or other attachments to connect the sling to the lifting equipment. Ensure that the hardware is in good condition and rated for the load.

-

Lifting Angle: Be aware of the lifting angle, as it affects the sling's capacity. The capacity of a sling decreases as the lifting angle deviates from the vertical. Refer to manufacturer guidelines or industry standards for angle reduction factors.

-

Avoid Abrasion: Protect the sling from abrasive surfaces and sharp edges by using wear pads, sleeves, or edge protection. Abrasion can weaken the sling and reduce its lifespan.

-

Sling Protection: Prevent the sling from coming into direct contact with chemicals, acids, or corrosive substances that can damage the stainless steel. Use appropriate covers or coatings when necessary.

-

Safe Distance: Maintain a safe distance from the load during lifting and lowering operations to avoid potential hazards in case of sling failure.

-

Regular Inspection: Implement a routine inspection and maintenance program for your stainless steel wire rope slings. Follow manufacturer recommendations for inspection intervals and procedures.

-

Training and Certification: Ensure that personnel involved in lifting operations are adequately trained and certified to use stainless steel wire rope slings safely. Knowledge of proper rigging techniques is crucial.

Benefits of Stainless Steel Wire Rope Slings

Stainless steel wire rope slings offer numerous advantages in various industries:

-

Corrosion Resistance: Stainless steel wire ropes are highly resistant to corrosion, making them suitable for use in harsh environments, including marine, offshore, and chemical industries.

-

Durability: Stainless steel wire rope slings have a long lifespan and are less susceptible to wear and tear, ensuring reliable and cost-effective performance.

-

High Strength: These slings have excellent strength-to-weight ratios, allowing them to handle heavy loads while remaining relatively lightweight and easy to handle.

-

Versatility: Stainless steel wire rope slings can be used for a wide range of lifting applications, from simple vertical lifts to complex multi-point rigging.

-

Flexibility: The flexibility of wire ropes allows for easy maneuvering around obstacles and adapting to various load shapes.

-

Low Stretch: Stainless steel wire ropes have minimal stretch, providing stability and control during lifting operations.

-

Low Maintenance: These slings require minimal maintenance compared to other materials, reducing downtime and costs.

Conclusion

Stainless steel wire rope slings are indispensable tools in the world of lifting and rigging. Choosing the right sling involves considering factors such as load capacity, sling configuration, diameter, wire rope grade, end fittings, environmental conditions, and inspection requirements. Proper usage and maintenance are crucial for ensuring safety during lifting operations.

The benefits of stainless steel wire rope slings, including corrosion resistance, durability, high strength, versatility, flexibility, low stretch, and low maintenance, make them valuable assets in industries where reliability and safety are paramount. By following best practices and adhering to safety guidelines, stainless steel wire rope slings can contribute to efficient and secure lifting operations, enhancing productivity and minimizing risks.

In conclusion, stainless steel wire rope slings are essential components in a wide range of industries, providing the strength and durability needed for safe and efficient lifting. Their resistance to corrosion and versatility make them a preferred choice in challenging environments, and when used correctly, they contribute to the overall safety and success of lifting operations.

No comments yet