In the world of manufacturing, precision and performance are paramount. From aerospace components to medical devices, industries demand materials that can withstand extreme conditions without compromising quality. One such material that has garnered significant attention in recent years is Polyether Ether Ketone, commonly known as PEEK. Its exceptional properties have made it a preferred choice for various applications, and with advancements in injection molding techniques, its potential has been further unlocked.

Peek injection molding, a widely used manufacturing process, involves injecting molten material into a mold cavity to create complex shapes with high accuracy and repeatability. While this method has been employed for decades, the introduction of PEEK plastic injection molding through Stebro Mold has revolutionized the production of components requiring high performance and reliability.

Polyether Ether Ketone offers a unique combination of properties that make it stand out among other thermoplastics. Even at elevated temperatures, it exhibits excellent mechanical strength, chemical resistance, and thermal stability. Moreover, it is biocompatible, making it suitable for medical implants and devices. These attributes make it an ideal choice for demanding aerospace, automotive, electronics, and healthcare applications.

PEEK plastic injection molding: Having a relatively high melting point

The PEEK plastic injection molding involves several critical considerations to ensure optimal results. One key factor is maintaining precise temperature control throughout the process. It has a relatively high melting point, typically around 343°C (649°F), requiring specialized equipment capable of reaching and maintaining these temperatures accurately. Also, proper melt flow and injection pressure are essential to achieve uniform mold cavity filling and prevent defects such as voids or warpages.

Injection mold manufacturers play a crucial role in successfully producing PEEK components. With advancements in mold design and manufacturing techniques, companies in regions like China have become leaders in creating high-quality injection molds for PEEK. These molds are engineered to withstand the demanding conditions of PEEK injection molding, ensuring consistent part quality and dimensional accuracy.

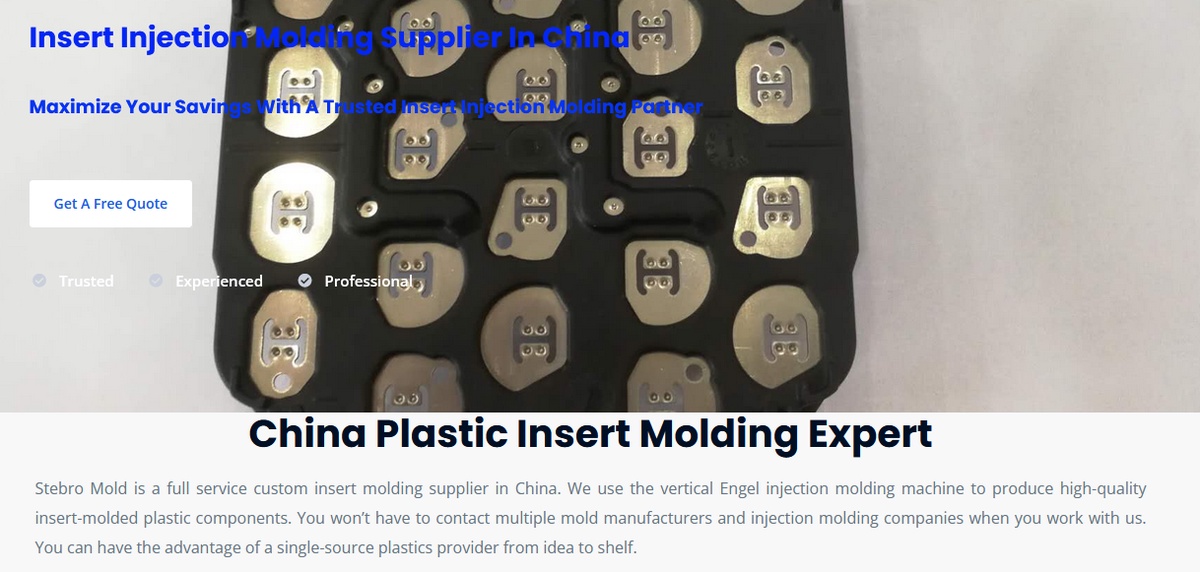

One notable advancement in injection molding PEEK is the development of multi-cavity molds. These molds allow for the simultaneous production of multiple parts in each cycle, significantly increasing productivity and reducing manufacturing costs. Manufacturers can achieve faster cycle times without compromising on part quality by optimizing the layout of the mold cavities and implementing advanced cooling systems.

One notable advancement in injection molding PEEK is the development of multi-cavity molds.

Furthermore, integrating advanced technologies such as computer-aided design (CAD) and simulation software has revolutionized mold design. Engineers can now simulate the injection molding process virtually, allowing them to identify potential issues such as flow imbalances or air traps before manufacturing the mold. This proactive approach helps streamline the development process and minimize time to market for new PEEK components.

Another area of innovation in PEEK injection mold China is the development of hybrid materials and composites. By incorporating fillers such as carbon fibers or glass fibers into the PEEK matrix, manufacturers can tailor the material properties to meet specific application requirements. These reinforced PEEK compounds offer enhanced strength, stiffness, and wear resistance, making them suitable for more demanding applications.

In conclusion, PEEK injection molding represents a significant advancement in the manufacturing industry, enabling the production of high-performance components with exceptional properties. With its unique mechanical, chemical, and thermal properties, it has become the material of choice for demanding applications across multiple industries. Coupled with advancements in mold design and manufacturing techniques of Stebro Mold, this kind of injection molding offers unparalleled innovation and product development opportunities. As the demand for lightweight and durable components continues to grow, it is poised to play an even more significant role in shaping the future of manufacturing.

For detailed information about injection mold China, switch to Stebro Mold to explore the quality of plastic mold company in China.

No comments yet