Hydraulic systems drive power and precision across countless industries. But before diving in, it's crucial to understand your specific needs. Here's a breakdown of key factors to consider:

Power and Control:

- Pressure: What force do you need to exert? Identify the maximum pressure required for your application.

- Flow Rate: How quickly does fluid need to move? Define the flow rate necessary for optimal performance.

- Control Precision: Do you need fine-tuned control or simple on/off functionality? Choose suitable valves accordingly.

System Environment:

- Operating Temperature: Will the system face extreme heat or cold? Select components and fluid compatible with the temperature range.

- Contamination Risk: Consider dust, moisture, or other potential contaminants and choose components with appropriate filtration.

- Duty Cycle: How frequently and intensively will the system operate? Opt for components designed for your expected usage.

Safety and Reliability:

- Pressure Relief Valves: Ensure overpressure protection through properly rated valves.

- Regular Maintenance: Schedule regular inspections and maintenance to prevent breakdowns.

By carefully considering these requirements, you can ensure your hydraulic system delivers optimal performance, efficiency, and safety. Remember, partnering with a trusted Best hand lever valve Manufacturer like Airmax Pneumatic can provide valuable expertise and ensure you get the perfect system for your needs.

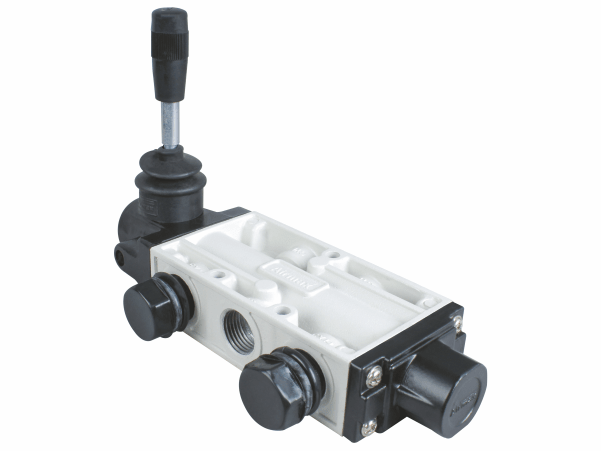

Key Factors to Consider in Hand Lever Valve Selection

Choosing the right hand lever valve is crucial for optimal performance and safety in your system. Here are some key factors to consider:

Application and Media:

- Fluids: Identify the type of fluid (water, gas, chemicals) and its properties (viscosity, corrosivity). This helps determine the right valve material and design.

- Pressure and Temperature: Consider the maximum pressure and temperature the valve will handle. Metal valves often excel in high-pressure situations, while plastic options might be suitable for lower pressures.

Functionality and Operation:

- Valve Function: What do you need the valve to do? On/off control, flow regulation, or mixing? Choose a valve design that suits your specific function.

- Actuation: Will the valve be manually operated with a hand lever, or require automated actuation (electric, pneumatic, hydraulic)?

- Frequency of Use: Consider how often the valve will be operated and choose a design that facilitates easy and comfortable actuation.

Size and Installation:

- Valve Size: Ensure the valve size matches your pipe diameter and flow requirements. An undersized valve can restrict flow and impact performance.

- Mounting Space: Check the available space for valve installation and consider the hand lever's length and clearance requirements.

- Compatibility: Ensure the hand lever is compatible with your chosen valve model and brand.

Additional Considerations:

- Safety Features: If applicable, consider valves with built-in safety features like pressure relief or flow limitation.

- Maintenance: Choose a valve design with easy access for maintenance and repairs.

- Regulations and Standards: Ensure the valve complies with relevant industry regulations and standards for your application.

Consulting with a reputable manufacturer like Best hand lever valve Manufacturer can help you select the perfect valve for your specific needs and ensure optimal performance, safety, and longevity.

Matching Valve Types to Hydraulic System Applications

Selecting the right valve for your hydraulic system is crucial for optimal performance, efficiency, and safety. But with numerous types available, choosing the best one can feel overwhelming. Fear not! Here's a breakdown of common valve types and their ideal applications:

Directional Control Valves:

- Spool valves: Versatile for precise flow direction control. Great for construction equipment and machine tools.

- Poppet valves: Compact and efficient for on/off control. Used in mobile hydraulics and smaller systems.

Pressure Control Valves:

- Relief valves: Protect systems from overpressure. Essential for safety in industrial applications.

- Reducing valves: Maintain constant downstream pressure regardless of upstream fluctuations. Ideal for sensitive equipment and actuators.

Flow Control Valves:

- Throttle valves: Adjust flow rate manually. Simple and cost-effective for basic systems.

- Proportional valves: Offer precise flow control through electrical or hydraulic signals. Perfect for demanding applications requiring accuracy.

For top-quality hand lever valves that match your specific hydraulic needs, look no further than Best hand lever valve Manufacturer: link to your website. Our expertise and diverse selection ensure you find the perfect valve for your application.

Pressure and Flow Rate Considerations for Optimal Performance

In any system involving fluid flow, striking the perfect balance between pressure and flow rate is crucial for optimal performance. But navigating this dynamic duo can get tricky. Here's a quick breakdown to guide you:

Higher Pressure:

- Boosts power: Delivers more force for tasks requiring high pressure, like industrial cleaning or jetting.

- Overcomes resistance: Pushes fluids through narrow pipes or against opposing pressure.

- Efficiency trade-off: Increased pressure often leads to higher energy consumption and potential wear on components.

Higher Flow Rate:

- Faster delivery: Quickly transports large volumes of fluids, ideal for applications like irrigation or filling containers.

- Reduced pressure drop: Minimizes energy loss due to friction in pipes and fittings.

- Control is key: Uncontrolled high flow can lead to spills, damage, or even system overload.

Finding the Sweet Spot:

- Application-specific: Every system has unique pressure and flow rate needs. Analyze your specific requirements to determine the ideal balance.

- Efficiency matters: Consider energy consumption and potential component wear when choosing your pressure and flow rate settings.

By understanding the interplay between pressure and flow rate, you can optimize your system's performance, saving energy and ensuring smooth operation.

Material Selection: Choosing the Right Build for Durability

Building for long-lasting performance starts with the right materials. Whether you're crafting a high-pressure pipeline or a delicate piece of machinery, choosing durable components makes all the difference. Here's how to select the best materials for your project:

Identify the Threat:

- Environmental: Will the material face extreme temperatures, harsh chemicals, or corrosive environments?

- Mechanical: Will it endure high pressure, constant abrasion, or heavy loads?

- Operational: Does it require specific conductivity, flexibility, or other performance properties?

Consider Material Options:

- Metals: Steel, stainless steel, and aluminum offer varying strength, corrosion resistance, and weight considerations.

- Plastics: From wear-resistant nylon to flexible PVC, plastics cater to specific needs like chemical compatibility and lightweight design.

- Ceramics: Excellent for high-temperature applications and extreme wear resistance, but can be brittle.

- Composites: Combining different materials like metal and plastic can provide unique strength, weight, and performance benefits.

Consult with Experts:

- Material suppliers: They possess in-depth knowledge of specific material properties and performance under various conditions.

- Design engineers: Their expertise can help you choose the optimal material based on your project's specific demands and constraints.

The right material choice can extend your project's lifespan, minimize maintenance costs, and ensure optimal performance. Don't hesitate to seek expert advice to ensure you build with durability in mind.

Size Matters: Sizing Hand Lever Valves for Your System

Choosing the right size hand lever valve is crucial for optimal performance and system longevity. Here's why getting the size right matters:

- Flow Rate: The valve size should match your system's flow requirements. An undersized valve restricts flow, causing pressure drops and reduced efficiency. Conversely, an oversized valve wastes energy and can lead to leaks.

- Pressure Rating: Ensure the valve's pressure rating exceeds your system's maximum operating pressure. Exceeding pressure limits can damage the valve and pose safety risks.

- Line Size: Match the valve size to your piping diameter for seamless integration. Mismatched sizes create turbulence and potential leak points.

- Viscosity: Consider the fluid's viscosity. Thicker fluids require larger valves for smooth flow.

With these factors in mind, choosing the best hand lever valve manufacturer becomes crucial. Look for a manufacturer with a proven track record, offering a wide range of sizes, pressure ratings, and materials to suit your specific needs. They should also provide expert guidance and support to ensure you select the perfect valve for your system.

Environmental Conditions and Their Impact on Valve Selection

Selecting the right valve for your application goes beyond just flow and pressure. Environmental conditions play a crucial role in ensuring optimal performance and longevity. Here's how:

- Temperature extremes: From scorching deserts to frigid tundras, valves need to withstand the heat without warping or the cold without becoming brittle. Consider materials like stainless steel for high temperatures and exotic alloys for cryogenic applications.

- Corrosion: Exposure to harsh chemicals, salt water, or acidic environments can eat away at valve components. Opt for materials like Monel or Hastelloy for superior corrosion resistance.

- Abrasive media: Slurries, sand, and other abrasive materials can wear down valve components prematurely. Look for valves with hardened internals or abrasion-resistant coatings.

- Dust and debris: Dusty environments can clog valves and impede their operation. Choose valves with tight seals and enclosed designs to minimize ingress.

- Moisture and humidity: Excessive moisture can lead to rust and other problems. Consider valves with water-resistant materials or protective coatings.

The Best hand lever valve Manufacturer understands these environmental factors and offers valves specifically designed to handle them. By carefully considering your application's environment, you can select a valve that delivers reliable performance and extends its lifespan.

No comments yet