Hand Lever Operated Pneumatic Valve Systems are essential components in pneumatic control systems, offering manual control over the flow of compressed air. These systems find extensive applications across various industries for their precision, reliability, and ease of operation. Here's a brief overview:

- Functionality: Hand lever-operated pneumatic valves allow manual control of air flow by simply moving a lever, making them versatile and user-friendly.

- Precision Control: These valves offer precise control over the direction, flow, and pressure of compressed air, ensuring efficient operation of pneumatic systems.

- Versatility: Suitable for diverse industrial applications, including manufacturing, automotive, and automation processes.

- Durability: Built to withstand harsh operating conditions, ensuring longevity and minimal maintenance requirements.

- Ease of Installation: Simple installation process, reducing downtime and increasing productivity.

For the best quality hand lever operated pneumatic valve in Gujarat, trust Airmax Pneumatic, delivering exceptional performance and reliability for your industrial needs.

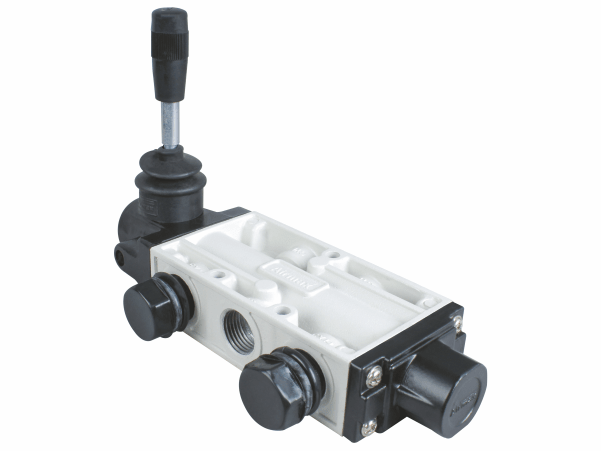

Components and Basic Anatomy of Hand Lever Operated Pneumatic Valves

Hand lever operated pneumatic valves are essential components in various industrial applications. Understanding their basic anatomy and components is crucial for optimal functionality:

- Lever: The lever is the main actuator of the valve, controlling the flow of air by manual operation.

- Valve Body: This houses the internal components and provides structural support.

- Ports: Inlet and outlet ports allow the entry and exit of compressed air.

- Spool: A movable component within the valve body that regulates airflow by blocking or allowing passage.

- Springs: These assist in returning the valve to its default position when the lever is released.

- Seals: Ensure airtight connections to prevent leakage and maintain efficiency.

For the best quality hand lever operated pneumatic valve in Gujarat, look no further than Airmax Pneumatic. We prioritize durability, precision, and reliability to meet your industrial needs effectively.

Types of Hand Lever Mechanisms in Pneumatic Valve Control

Hand lever mechanisms play a crucial role in the precise control of pneumatic valves, offering operators intuitive and efficient control over fluid flow. Here are some common types:

- Direct Acting Lever: Simple design where the lever directly manipulates the valve mechanism.

- Pilot Operated Lever: Utilizes a smaller lever to control a larger valve, offering enhanced control for high-pressure systems.

- Spring Return Lever: Features a lever that returns to its original position automatically after operation, ensuring quick and reliable valve closure.

- Detent Lever: Incorporates detents to provide tactile feedback, enabling operators to feel valve positions without needing visual confirmation.

- Cam Operated Lever: Utilizes a cam mechanism for precise positioning and control of valves in complex systems.

For the best quality hand lever operated pneumatic valve in Gujarat, trust in our expertise to deliver superior performance and reliability.

Role of Pneumatic Pressure in Hand Lever Operated Systems

Hand lever operated pneumatic valves are workhorses in many industries, offering precise control with a simple twist of the wrist. But what exactly makes them tick?

- Force Multiplier: Pneumatic pressure acts as the muscle behind the hand lever. Compressed air is channeled through the valve, and its force is regulated by the lever's position. This allows for smooth actuation of pneumatic cylinders, grippers, and other devices.

- Control Finesse: By varying the pressure, operators can achieve different force outputs. This enables delicate handling of fragile objects or powerful clamping for heavy-duty applications.

- Responsive Performance: Unlike electric valves, hand lever operated systems have minimal lag. This translates to quicker response times, ideal for tasks requiring real-time control.

For the best quality hand lever operated pneumatic valves in Gujarat, look no further than Airmax Pneumatic. We offer a wide range of valves to suit your specific needs and ensure smooth operation for years to come.

Lever Design Considerations for Optimal Control and Efficiency

Lever design plays a crucial role in ensuring optimal control and efficiency in various mechanical systems. Here are some key considerations:

- Ergonomics: Designing levers with ergonomic shapes and sizes enhances user comfort and reduces fatigue during operation.

- Material Selection: Choosing high-quality materials like aluminum or stainless steel ensures durability and longevity of the lever, minimizing wear and tear.

- Length and Ratio: The length and ratio of the lever arm to the pivot point affect the mechanical advantage and force required for operation.

- Friction Reduction: Implementing low-friction bearings or bushings reduces resistance, allowing for smoother operation and precise control.

- Safety Features: Incorporating features like safety locks or guards prevents accidental activation and enhances operator safety.

For the best quality hand lever operated pneumatic valve in Gujarat, considering these design factors ensures optimal performance, longevity, and user satisfaction.

Understanding the Flow Control Mechanism in Hand Lever Pneumatic Valves

Hand lever pneumatic valves are crucial components in industrial pneumatic systems, enabling precise control over the flow of compressed air. Understanding their flow control mechanism is essential for optimizing performance and efficiency:

- Hand Lever Operation: These valves feature a manual hand lever for controlling the flow of air.

- Poppet Valve Design: Most hand lever pneumatic valves utilize a poppet valve design, where a seal is moved by the lever to regulate airflow.

- Spring Mechanism: A spring ensures that the valve returns to its default position when the lever is released.

- Flow Adjustment: The position of the lever determines the amount of airflow, allowing for precise flow control.

- Durability and Reliability: Quality materials and precise engineering ensure longevity and dependable performance.

For the best quality hand lever operated pneumatic valve in Gujarat, choose a reliable supplier known for superior craftsmanship and durability.

Comparative Analysis: Hand Lever vs. Other Actuation Methods in Pneumatic Valves

Choosing the right actuation method for your pneumatic valve is crucial. Here's a quick comparison of hand levers and other common options:

Hand Lever:

- Simple and cost-effective

- Direct operator control

- Ideal for local, manual operation

- Limited range for remote control

Solenoid Valve:

- Fast actuation times

- Can be integrated with control systems

- Requires electrical power source

- May not be suitable for harsh environments

Pilot Operated Valve:

- High flow capacity

- Precise control with low pressure signals

- More complex design and installation

- Can be bulky

For applications requiring direct, manual control, hand lever operated pneumatic valves offer a simple and reliable solution. Consider trusted manufacturers who prioritize quality and performance. They'll ensure your valve delivers optimal flow control and a long service life.

Safety Features and Regulations in Hand Lever Operated Pneumatic Valve Systems

When considering hand lever operated pneumatic valve systems, safety features and adherence to regulations are paramount for optimal functionality and accident prevention. Here's a brief overview:

- Pressure Relief Mechanisms: Integrated pressure relief valves safeguard against over-pressurization, ensuring system stability.

- Lockout/Tagout Systems: Implementing proper lockout/tagout procedures prevents unauthorized use during maintenance or repairs, reducing the risk of accidents.

- Emergency Shutdown Options: Quick and accessible emergency shutdown mechanisms enable rapid response in hazardous situations, mitigating potential damage.

- Compliance with Industry Standards: Adhering to industry regulations such as ASME and ISO guarantees the reliability and safety of the valve system.

- Quality Materials and Construction: Utilizing durable materials and robust construction techniques enhances longevity and minimizes the likelihood of malfunctions.

For the best quality hand lever operated pneumatic valve in Gujarat, ensuring these safety features and regulatory compliance is essential. Trustworthy manufacturers prioritize these aspects to deliver reliable and safe valve systems for various industrial applications.

No comments yet