In the world of industrial automation, pneumatic systems play a pivotal role in controlling the movement of various components. Among the essential components of these systems are pneumatic valves, which regulate the flow of compressed air to actuate different mechanisms. One key type of pneumatic valve is the 5 Way 2 Position Pneumatic Valve, which serves as a fundamental element in automation processes.

- Versatile Functionality: These valves are designed to divert the flow of compressed air in five different directions while maintaining two distinct positions. This versatility makes them invaluable for complex automation tasks.

- Precise Control: Automation processes often require precise control over the movement of actuators and cylinders. 5 Way 2 Position Pneumatic Valves allow for precise and efficient control, ensuring seamless operation.

- Common Applications: They find applications in industries such as manufacturing, automotive, and robotics, where controlling the direction of pneumatic pressure is crucial for task execution.

- Reliable Performance: These valves are known for their durability and reliability, contributing to the overall efficiency and safety of automated systems.

In summary, the 5 Way 2 Position Pneumatic Valve is a vital component in the world of automation, offering precise control and reliability in diverse industrial applications.

Enhancing Control and Precision: Role of 5 Way 2 Position Valves

In the world of pneumatic systems, precision and control are paramount. The key to achieving these objectives lies in the strategic deployment of specialized components, such as 5 Way 2 Position Valves. These versatile valves play a pivotal role in optimizing pneumatic systems, offering a wide range of benefits:

- Directional Flexibility: A 5 Way 2 Position Valve provides five distinct flow paths and two positions, offering unparalleled control over the direction of airflow. This versatility is essential for complex automation tasks.

- Enhanced Control: These valves allow for precise regulation of pneumatic actuators, making them indispensable in applications where accuracy and repeatability are crucial.

- Reduced Energy Consumption: By enabling selective control of air supply to various components, these valves help conserve energy, promoting cost-efficiency and eco-friendliness.

- Increased Productivity: The ability to switch between two distinct positions swiftly enhances the speed and efficiency of pneumatic systems, ultimately boosting productivity.

- Customization: 5 Way 2 Position Valves can be tailored to meet specific system requirements, making them suitable for a wide array of industries and applications.

When it comes to optimizing pneumatic systems for precision and control, the 5 Way 2 Position Pneumatic Valve emerges as an indispensable component, offering versatility and reliability that elevate the performance of any system.

Optimizing Workflow: Benefits of Using 5 Way 2 Position Valves

In the world of pneumatics, efficiency is paramount, and choosing the right components can make all the difference. When it comes to optimizing workflow, 5 Way 2 Position Pneumatic Valves are indispensable. These valves offer a host of advantages that streamline processes and enhance productivity. Here's a closer look at the benefits:

- Versatility: 5 Way 2 Position Valves provide multiple actuation options, making them suitable for a wide range of applications.

- Simplified Control: They enable precise control over pneumatic systems, reducing the likelihood of errors and improving overall efficiency.

- Space Efficiency: These valves are compact, saving valuable workspace and allowing for more flexible system design.

- Reduced Air Consumption: With their two-position operation, they help conserve compressed air, leading to cost savings and a more environmentally friendly operation.

- Enhanced Safety: The reliability of these valves ensures the safe operation of machinery, minimizing the risk of accidents.

- Quick Response: They offer rapid response times, making them ideal for applications requiring fast and precise movements.

- Durability: 5 Way 2 Position Pneumatic Valves are built to last, reducing downtime and maintenance costs.

Incorporating a 5 way 2 position pneumatic valve into your workflow can significantly enhance your operational efficiency and save both time and resources. Make the smart choice for your pneumatic systems and experience the benefits firsthand.

Key Components and Features of 5 Way 2 Position Pneumatic Valves

5 Way 2 Position Pneumatic Valves are essential components in pneumatic systems, responsible for controlling the flow of compressed air to different actuators and devices. Understanding their key components and features is crucial for efficient system design and operation:

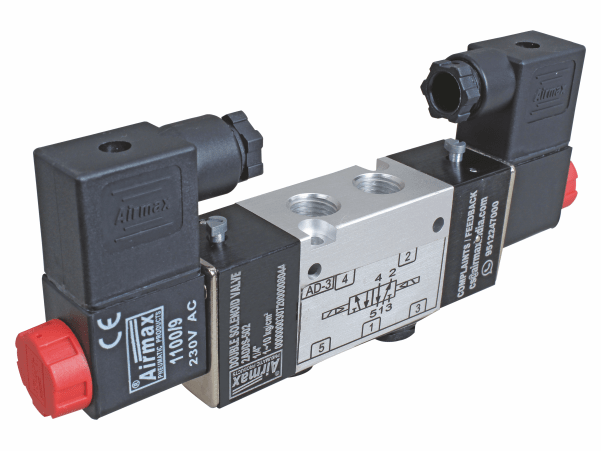

Valve Body:

- Typically made from durable materials like aluminum or stainless steel.

- Houses the internal components and provides structural integrity.

Actuation Method:

- Operated manually, electrically, or pneumatically to switch between positions.

- Common actuation methods include solenoids, levers, or buttons.

Ports:

- Equipped with five ports for connecting air supply, exhaust, and actuator ports.

- Ports labeled P, A, B, R, and S for Pressure, Actuator 1, Actuator 2, Exhaust, and Supply, respectively.

Spool or Poppet:

- The heart of the valve responsible for directing airflow.

- In a 2-position valve, it moves between two positions to open or close different paths.

Flow Capacity:

- Varies depending on valve size and design.

- Ensures the valve can handle the required airflow for the application.

Durability and Reliability:

- Designed for long service life and minimal maintenance.

- Resistant to wear and corrosion for reliable operation.

Seamless Integration: 5 Way 2 Position Valves in Automated Systems

In today's rapidly evolving industrial landscape, automation has become the key to efficiency and precision. Among the critical components that enable seamless automation are 5-way 2-position pneumatic valves. These valves play a pivotal role in various automated systems, ensuring smooth and precise control over pneumatic operations.

- Versatility: 5-way 2-position pneumatic valves offer versatile control, enabling engineers to direct air flow precisely in automated systems, making them suitable for a wide range of applications.

- Optimized Functionality: These valves allow for quick and precise switching between two distinct positions, enhancing the overall functionality and efficiency of automated processes.

- Reduced Downtime: Their robust construction and reliable operation minimize downtime in industrial settings, reducing production interruptions and maintenance costs.

- Compatibility: 5-way 2-position pneumatic valves seamlessly integrate with various automation technologies, making them compatible with PLCs, sensors, and other control systems.

- Energy Efficiency: By controlling the flow of compressed air with precision, these valves contribute to energy savings, promoting eco-friendly automation solutions.

5-way 2-position pneumatic valves are indispensable components in automated systems. Their versatility, reliability, and compatibility make them essential for achieving seamless integration and optimal performance in a wide range of industrial applications.

Maximizing Efficiency: How 5 Way 2 Position Valves Improve Automation

In the world of automation, efficiency is paramount, and one crucial component that plays a pivotal role in achieving optimal efficiency is the 5 way 2 position pneumatic valve. These valves are essential in various industrial applications, and their ability to enhance automation processes cannot be overstated. Here's how these valves make a difference:

- Diverse Control Options: 5 way 2 position valves offer multiple control options, allowing for precise manipulation of pneumatic systems. This versatility ensures that automation processes can be fine-tuned to meet specific requirements.

- Reduced Air Consumption: These valves are designed to minimize air consumption during operation, resulting in cost savings and reduced environmental impact.

- Enhanced Workflow: By seamlessly controlling the direction and flow of compressed air, these valves enable smoother and faster automation workflows. This, in turn, increases productivity and reduces downtime.

- Improved Safety: The reliability of 5 way 2 position valves enhances safety by ensuring that automation systems respond predictably to commands, reducing the risk of accidents.

- Compact Design: These valves come in compact designs, making them suitable for tight spaces, a crucial advantage in today's space-constrained industrial environments.

In summary, the 5 way 2 position pneumatic valve is a vital component for maximizing efficiency in automation. Its versatility, air-saving capabilities, and safety enhancements make it an indispensable tool in modern industrial settings.

Safety and Reliability: The Importance of 5 Way 2 Position Valve Selection

When it comes to pneumatic systems, the selection of the right components is crucial to ensure safety and reliability. Among these components, the 5 way 2 position pneumatic valve plays a pivotal role. This valve configuration is widely used in various industrial applications and offers several advantages, making it essential to choose the right one for your specific needs. Here's why:

- Precise Control: 5 way 2 position valves allow for precise control of pneumatic actuators, ensuring accurate positioning and movement.

- Versatility: They are versatile and can be used in a wide range of applications, including automation, robotics, and manufacturing processes.

- Safety: Selecting the appropriate valve ensures the safety of personnel and equipment by preventing unintended actuator movements or system failures.

- Reliability: The right valve choice enhances system reliability, reducing downtime and maintenance costs.

- Efficiency: Proper valve selection optimizes the efficiency of pneumatic systems, leading to energy savings and improved overall performance.

- Compatibility: Ensuring compatibility with other system components is crucial to avoid operational issues and maximize efficiency.

In summary, when working with pneumatic systems, the selection of a 5 way 2 position pneumatic valve should not be taken lightly. The right choice can significantly impact safety, reliability, and overall system performance, making it a critical decision in any industrial setup.

Applications and Industries Leveraging 5 Way 2 Position Valve Technology

5-way 2-position pneumatic valve technology has revolutionized various industries by providing precise control over fluid and gas flow. This versatile technology offers numerous applications across diverse sectors, enhancing efficiency and performance. Here are some key applications and industries that leverage the power of 5-way 2-position pneumatic valves:

Manufacturing:

- Automated assembly lines use these valves to control pneumatic actuators for precise movement and positioning of components.

- Pneumatic clamping systems ensure secure workpiece holding during machining processes.

Aerospace:

- Aircraft landing gear systems rely on these valves for smooth and reliable landing gear deployment and retraction.

- Cabin pressurization systems maintain passenger comfort and safety.

Automotive:

- Automated welding and painting robots use 5-way 2-position valves for precise control of pneumatic cylinders.

- Engine testing and calibration equipment benefit from quick and accurate air supply control.

Medical Devices:

- Ventilators use these valves to manage airway pressure and assist patients with breathing difficulties.

- Laboratory automation equipment relies on them for precise fluid handling.

Mining and Construction:

- Heavy machinery employs these valves for controlling pneumatic tools and hydraulic systems.

- Safety mechanisms for equipment like excavators and bulldozers enhance operator protection.

5-way 2-position pneumatic valve technology plays a crucial role in enhancing the efficiency, safety, and precision of processes in these industries and many more. Its versatility and reliability make it a vital component in various applications.

No comments yet