These valves are essential components in any pneumatic system, controlling the flow and direction of compressed air. Imagine them as the conductors of an orchestra, directing air pressure to power cylinders, motors, and other actuators.

- Function First: Their primary purpose is to start, stop, and change the direction of airflow. This precise control allows for movement and operation of various pneumatic machinery.

- Variety is Key: Directional control valves come in different configurations, typically categorized by the number of ports (2-way, 3-way, 4-way) and their actuation method (manual, solenoid, pilot operated). Choosing the right valve depends on the specific needs of your application.

For all your pneumatic needs, consider partnering with a Top Pneumatic Directional Control Valve Manufacturer in India. These companies offer a wide range of valves to ensure you have the perfect fit for your project.

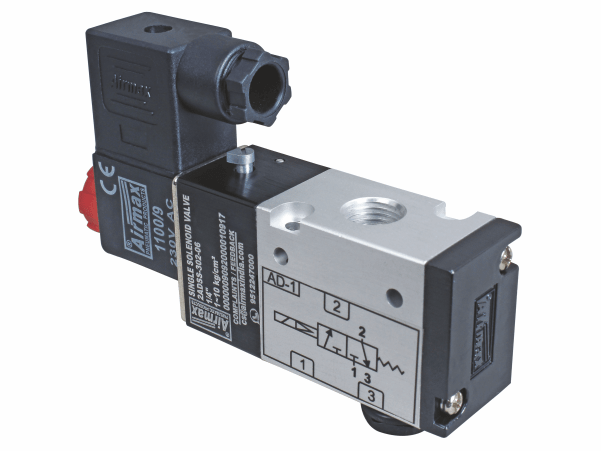

Solenoid-Operated Pneumatic Directional Control Valves: Functionality and Applications

These valves use electromagnetism (solenoids) to control compressed air flow in pneumatic systems. By switching between open and closed states, they direct air to actuators like cylinders, driving movement and automation.

- Applications: They're vital for precise control in various industries:

- Manufacturing: Operate robotic arms, assembly lines, and material handling equipment.

- Packaging: Power automated processes like filling, sealing, and palletizing.

- Construction: Control air tools, brakes, and door mechanisms.

Finding the right manufacturer is crucial for quality and performance. Research Indian companies to ensure they offer valves suited for your specific needs and applications.

Manually Operated Pneumatic Directional Control Valves: Features and Uses

Manually operated pneumatic directional control valves offer precise air flow control with a simple twist or push. These valves are ideal for applications requiring direct operator intervention.

Features:

- Simple and reliable design

- Available in various port configurations (2/2, 3/2, 5/2) for diverse needs

- Easy to maintain

- Durable construction for long-lasting performance

Uses:

- Starting and stopping pneumatic actuators (cylinders, motors)

- Switching air flow direction in a circuit

- Machine operation control

- Ideal for maintenance and troubleshooting

For top-quality manually operated pneumatic directional control valves, look no further than the leading manufacturers in India. Research these companies to find the perfect valve for your specific application.

Pilot-Operated Pneumatic Directional Control Valves: Mechanisms and Advantages

Pilot-operated pneumatic directional control valves are workhorses in industrial automation. They use a small, pilot signal to control a larger flow of compressed air, offering several key advantages:

- Reduced Operator Effort: A small pilot signal can handle high-pressure or high-flow air, minimizing the force needed for operation. This is ideal for remote control or situations where human actuation isn't feasible.

- Versatility in Actuation: Pilot valves can be actuated by various means, including solenoids, limit switches, or even human operators. This allows for flexible integration into different control systems.

- Reduced Wear and Tear: By separating the control signal from the main flow, pilot valves experience less wear on the internal components, leading to longer lifespans.

For superior performance and reliability in your pneumatic systems, consider partnering with a Top Pneumatic Directional Control Valve Manufacturer in India. Their expertise ensures you get the perfect valve for your specific application.

Proportional Pneumatic Directional Control Valves: Precision Control in Various Settings

Need ultra-precise control over air flow in your pneumatic systems? Look no further than proportional pneumatic directional control valves. These innovative valves offer a significant leap in accuracy compared to traditional on/off options.

- Precise Flow Control: Unlike standard valves with limited positions, proportionals adjust flow rate smoothly based on an electrical signal. This enables fine-tuned control for tasks requiring varying air pressure.

- Enhanced Efficiency: By delivering only the necessary air pressure, proportional valves optimize energy usage and reduce system wear.

- Versatile Applications: Their ability to handle a wide range of flow rates makes them ideal for diverse applications, from delicate assembly lines to high-speed material handling.

For top-of-the-line proportional pneumatic directional control valves, consider partnering with a leading manufacturer in India. Their expertise ensures you get reliable, high-performance valves tailored to your specific needs.

Diverter Valves: Redirecting Air Flow for Multiple Applications

Diverter valves are essential components in pneumatic systems, providing precise control over air flow direction. They act like traffic signals for air, ensuring it reaches the desired destination within your machinery.

- Versatility: Diverter valves come in various configurations, from simple two-way to complex multi-positional options. This allows them to be integrated into a wide range of applications.

- Precise Control: By strategically positioning diverter valves, you can control the activation and deactivation of pneumatic cylinders, regulate air pressure, and optimize processes requiring airflow direction changes.

- Durability: Built to withstand the demands of industrial environments, diverter valves are known for their reliability and long service life.

Looking for a reliable diverter valve solution? Consider partnering with a Top Pneumatic Directional Control Valve Manufacturer in India. Their expertise and commitment to quality will ensure you get the perfect valve for your specific needs.

Selector Valves: Switching Between Different Pneumatic Circuits

Selector valves are vital components in pneumatic systems, offering precise control over airflow direction. They act as a central hub, allowing you to switch between different pneumatic circuits with ease. Here's how they function:

- Multiple Ports: Selector valves come with various port configurations, enabling connection to multiple circuits.

- Directional Control: By rotating or positioning the valve handle, you control the flow of compressed air, directing it to the desired circuit.

- Simplified Operations: Selector valves eliminate the need for complex piping changes, streamlining operation and reducing downtime.

Applications:

- Machine Operation Modes: Select between automatic and manual operation for machinery.

- Tool Selection: Activate different pneumatic tools based on the task at hand.

- Circuit Sequencing: Control the order of operations within a complex pneumatic system.

Top Pneumatic Directional Control Valve Manufacturer in India offers a wide range of selector valves to meet your specific needs. Explore their selection to find the perfect valve for optimal control within your pneumatic system.

Check Valves: Preventing Reverse Flow in Pneumatic Systems

Pneumatic systems rely on pressurized air to power actuators and drive various industrial processes. But what happens when pressure drops or reverses? Here's where check valves step in.

- One-way traffic: These automatic valves allow compressed air to flow freely in one direction, typically towards the actuator.

- Preventing backflow: When pressure drops or tries to reverse, a spring-loaded mechanism within the check valve seals the passage, stopping unwanted flow.

- Protecting components: This one-way flow ensures proper functioning of pneumatic circuits and safeguards equipment from damage caused by reverse pressure.

By preventing backflow, check valves are crucial components in pneumatic systems. To ensure optimal performance, consider partnering with a Top Pneumatic Directional Control Valve Manufacturer in India for high-quality check valve solutions.

Flow Control Valves: Regulating the Speed of Pneumatic Actuators

In pneumatic systems, flow control valves are essential for regulating the speed of pneumatic actuators. By adjusting the airflow rate, you can directly control how fast the actuator extends and retracts.

- Smoother Operation: Flow control valves contribute to smoother and more reliable actuator movement. Uncontrolled, high-speed airflow can lead to jerky movements and increased wear. A well-adjusted flow control valve prevents this, promoting a steadier operation.

- Deeper Control: It's important to remember that flow control valves manage speed, while pressure regulators govern force. For consistent speed control, consider using a flow control valve on the exhaust port alongside a pressure regulator on the input.

Looking for Top Pneumatic Directional Control Valve Manufacturers in India? Ensuring smooth operation and precise control in your pneumatic systems requires high-quality components. Research reputable manufacturers offering a wide range of flow control valves and other pneumatic elements.

Choosing the Right Type of Pneumatic Directional Control Valve for Your Application

Selecting the perfect pneumatic directional control valve is crucial for optimal performance in your system. Here are some key factors to consider:

- Functionality: Identify the number of ports (2-way, 3-way, etc.) and desired flow direction control (single or double) required for your application.

- Actuation Method: Will your valve be solenoid operated, pilot operated, or manually actuated? Consider actuation speed and response time.

- Flow Capacity: Ensure the valve can handle the required flow rate to avoid inefficiencies or sluggish operation.

- Pressure Rating: Match the valve's pressure rating to your system's operating pressure for safe and reliable function.

By carefully considering these aspects, you'll be well on your way to selecting the ideal valve. To ensure top-quality performance, look for a trusted manufacturer like Top Pneumatic Directional Control Valve Manufacturer in India. They offer a comprehensive range of valves to meet your specific needs.

No comments yet