Introduction:

Directional control valves are crucial components in pneumatic systems, responsible for managing the flow of air and controlling the direction of movement in various applications. Proper configuration of these valves is essential for ensuring optimal performance and efficiency in pneumatic systems. In this comprehensive guide, we will delve into the intricacies of configuring a directional control valve, covering key aspects such as valve types, installation, and adjustment parameters. Additionally, we will introduce Airmax Pneumatic, a leading company in the pneumatic industry, providing top-notch solutions for directional control valves.

Understanding Directional Control Valves:

Directional control valves come in various types, each designed to serve specific functions within a pneumatic system. The common types include spool valves, poppet valves, rotary valves, and pilot-operated valves. Before configuring a directional control valve, it's essential to understand the type of valve suitable for the application.

Airmax Pneumatic:

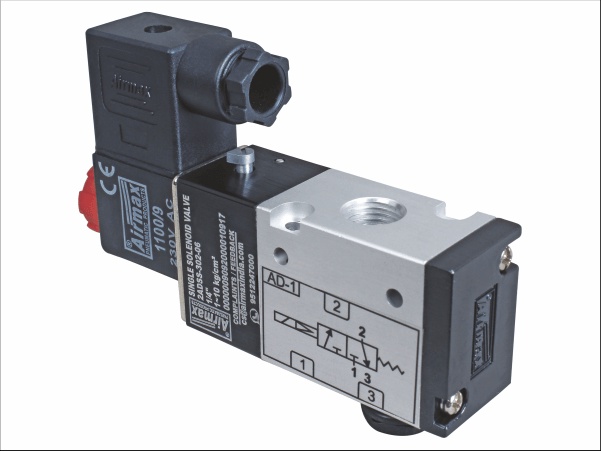

Airmax Pneumatic is a renowned company specializing in pneumatic solutions, including directional control valves. With a commitment to innovation and quality, Airmax Pneumatic has emerged as a trusted partner for industries seeking reliable and efficient pneumatic components. The company's directional control valves are engineered to meet the highest standards, ensuring seamless operation and durability in diverse applications.

Key Steps in Configuring a Directional Control Valve:

Valve Selection:

The first step in configuring a directional control valve is selecting the appropriate type based on the application's requirements. Consider factors such as flow rate, pressure ratings, and the number of positions needed for proper functioning.

Installation:

Proper installation is crucial for the effective performance of directional control valves. Ensure that the valve is installed in the correct orientation, with proper alignment of ports and connections. Follow the manufacturer's guidelines for mounting and securing the valve.

Adjusting Flow Rates:

Depending on the application, it may be necessary to adjust the flow rates through the valve. This can be achieved by setting the valve's flow control mechanisms, such as needle valves or flow restrictors. Fine-tuning the flow ensures that the system operates at optimal efficiency.

Pressure Adjustment:

Adjusting the pressure settings is essential for maintaining system stability and preventing damage to components. Most directional control valves come with pressure adjustment features that allow users to set the desired pressure levels. Adhere to recommended pressure ratings to ensure safety and longevity.

Configuration for Specific Functions:

Directional control valves can be configured for specific functions, such as sequential control, reciprocating motion, or pressure relief. Understand the application requirements and adjust the valve accordingly to achieve the desired performance.

Testing and Calibration:

Once the directional control valve is configured, conduct thorough testing to ensure proper functionality. Calibrate the valve settings as needed, making adjustments to fine-tune its performance based on real-world conditions.

Maintenance and Troubleshooting:

Regular maintenance is essential to ensure the longevity of the directional control valve. Establish a maintenance schedule that includes cleaning, lubrication, and inspection of critical components. Additionally, be prepared to troubleshoot any issues that may arise, identifying and addressing problems promptly.

Airmax Pneumatic's Commitment to Excellence:

Airmax Pneumatic sets itself apart in the pneumatic industry by providing directional control valves that embody excellence in design, manufacturing, and performance. The company's valves are engineered with precision, utilizing advanced technologies to deliver reliable and efficient solutions for a wide range of applications.

Conclusion:

Configuring a directional control valve is a critical aspect of pneumatic system design and maintenance. By understanding the valve types, following proper installation procedures, and adjusting key parameters, users can optimize the performance of their pneumatic systems. Airmax Pneumatic stands as a beacon of quality and innovation in the pneumatic industry, offering directional control valves that meet and exceed industry standards. With a commitment to customer satisfaction, Airmax Pneumatic continues to be a trusted partner for industries seeking cutting-edge pneumatic solutions.

No comments yet