High-shear mixers are indispensable tools in various industries, offering efficient and effective mixing solutions for a wide range of applications. Whether you're working in pharmaceuticals, food processing, cosmetics, or chemical manufacturing, selecting the right high-shear mixer is crucial for achieving optimal results. In this blog post, we'll explore the key factors to consider when choosing a high-shear mixer to meet your specific mixing needs.

Understanding Shear Mixing

High shear mixing involves the application of intense mechanical forces to a mixture to achieve through dispersion, emulsification, and particle size reduction. This process is essential for creating uniform and stable products in industries where consistency and quality are paramount.

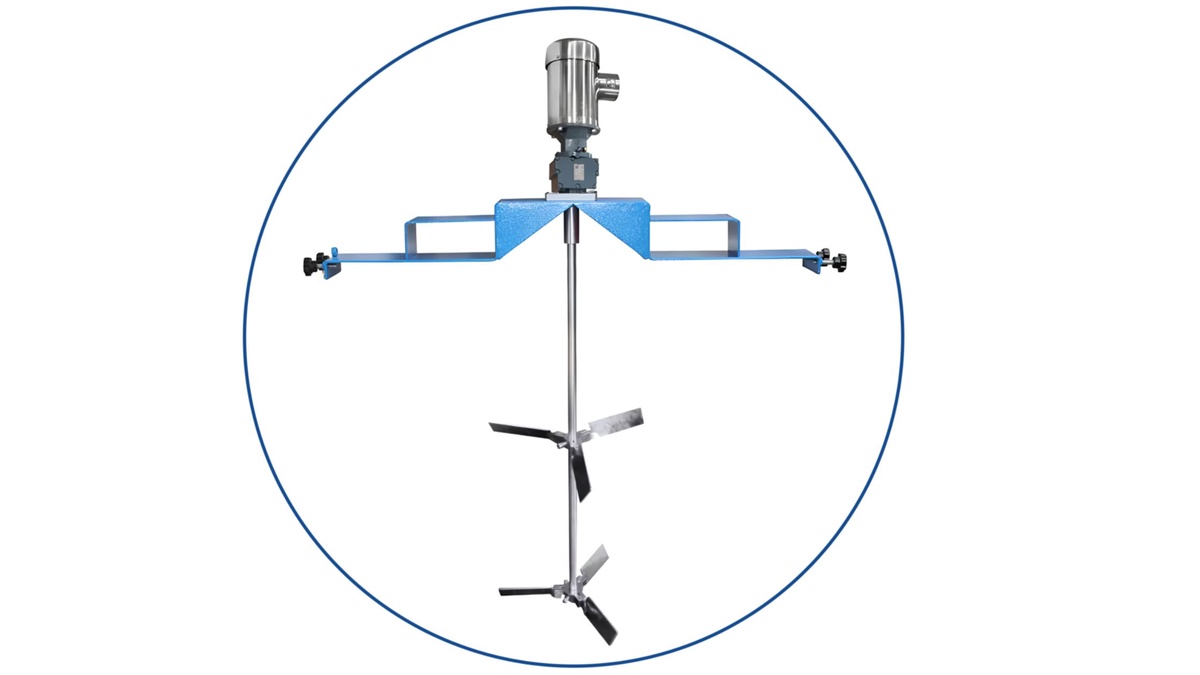

High-shear mixers employ various mechanisms to generate shear forces, including rotor-stator configurations, high-speed impellers, and inline rotor designs. Each type of mixer offers distinct advantages and is suitable for specific applications.

Factors to Consider

Application Requirements:

The first step in choosing a suitable high-shear mixer is to define your application requirements. Consider factors such as the viscosity of your ingredients, desired particle size distribution, and processing volume. Different mixers are designed to handle specific viscosities and batch sizes, so matching your mixer to your application needs is essential.

Type of Mixer:

High-shear mixers come in different configurations, including batch, inline, and multi-stage mixers. Batch mixers are suitable for small to medium-sized batches and offer flexibility in formulation changes. Inline mixers are ideal for continuous processing and are commonly used in the pharmaceutical and chemical industries. Multi-stage mixers combine mixing stages in a single unit, allowing for complex processing operations.

Mixer Design:

Pay attention to the design features of the mixer, including the geometry of the mixing chamber, the configuration of the rotor and stator, and the construction material. Look for mixers with robust construction and hygienic design features to ensure ease of cleaning and maintenance, particularly in industries like food and pharmaceuticals where cleanliness is critical.

Power and Speed:

Consider your application's power and speed requirements when selecting a high-shear mixer. Higher horsepower and speed capabilities allow for more intense mixing and accommodate higher-viscosity materials. However, be mindful of excessive shear forces, which can lead to product degradation or overheating in sensitive formulations.

Process Control:

Look for mixers with advanced process control features like variable speed drives, temperature monitoring, and pressure regulation. These features allow for precise control over the mixing process and enable optimization of product quality and consistency.

Case Studies and Testimonials

Before making a final decision, reviewing case studies and testimonials from other users with experience with the mixer you're considering can be helpful. Look for examples of successful applications similar to yours, and consider contacting manufacturers for additional information or references.

Final Thoughts

Choosing a suitable high-shear mixer is essential for achieving optimal mixing results in your industry. By considering factors such as application requirements, mixer type, design features, power and speed capabilities, and process control features, you can select a mixer that meets your specific mixing needs and delivers consistent, high-quality products. With a suitable high-shear mixer in your arsenal, you can streamline your production processes, improve efficiency, and maintain a competitive edge in your market.

No comments yet