In the field of precision manufacturing, two advanced technologies have gained recognition for their remarkable capability to create detailed parts with unmatched accuracy: CNC cutting and laser cutting. These methods are utilized across various industries, including steel fabrication, automotive manufacturing, and aerospace engineering. Each technique offers distinct advantages, setting them apart in how they work with materials.

CNC cutting, short for Computer Numerical Control cutting, employs computer-controlled machinery equipped with specialized tools. It enables precise, efficient production by following exact design specifications created using software such as CorelDRAW or AutoCAD. CNC cutting is particularly favored for its versatility in handling various materials and intricate designs, revolutionizing manufacturing processes across industries, reducing human error, and significantly enhancing efficiency and productivity.

In contrast, laser cutting, also guided by a CNC system, relies on the power of high-energy light beams to create the desired shapes. The precision achieved through laser cutting is remarkable, allowing for intricate designs with clean, sealed edges, making it an ideal choice for applications that demand the utmost precision and aesthetic quality.

Both CNC and laser cutting techniques excel in their respective ways, offering manufacturers and designers the flexibility to choose the method that best suits their specific needs, whether it be the versatility of CNC cutting or the precision of laser cutting, in their pursuit of crafting precision-engineered components.

What is CNC Cutting?

CNC, short for Computer Numeric Control, is a technology that employs specialised tools guided by computer systems to efficiently produce products. When it comes to CNC laser cutting, a skilled designer uses software like CorelDRAW or AutoCAD to create a precise design based on the customer's requirements. Once the design is perfected, a piece of metal or another material is placed on the cutting surface.

The computer sends instructions to the CNC cutting machine, which then interprets the design. With an approved prototype, the operator can start processing multiple products. To execute the cuts, the cutting tool moves back and forth and side-to-side along the axes, closely following the shape of the design.

CNC laser cutting is especially popular in industries that demand precise and complex cuts on various materials, such as steel. It has revolutionised manufacturing processes by speeding up production and reducing human error. This technology has significantly enhanced efficiency and productivity in sectors like automotive manufacturing, aerospace engineering, and furniture production.

In essence, CNC cutting involves the use of computer-controlled machines to accurately cut materials based on predefined designs. While both CNC and laser cutting have their merits, CNC technology has shown remarkable versatility in multiple industries by offering precise and efficient solutions for metal fabrication and other material-cutting needs.

Laser Cutting: The Power of Precision Through Heat

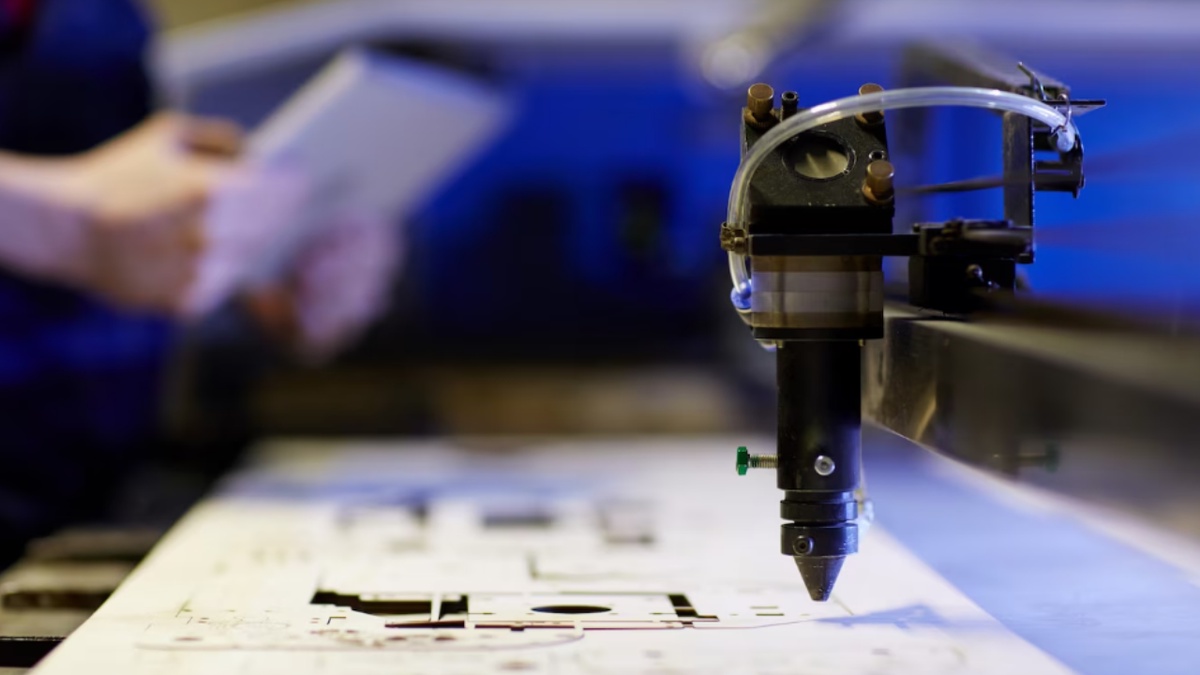

Like CNC metal cutting, a CNC system guides a laser metal cutting machine. However, the key difference lies in how the cutting happens. Instead of a cutting tool, laser cutting relies on the power of heat to shape the desired product. Traditional metal CNC cutting physically carves out the design, but laser cutting uses a high-energy light beam to burn through the metal material.

Laser cutting boasts several unique advantages:

- Precision: The primary reason for choosing laser metal cutting is its incredible precision. While CNC cutting tools have limited widths, a laser beam can be set to an astonishingly small 0.1mm. This level of precision allows for detailed cuts that are hard to achieve with traditional CNC cutting methods.

- Clean and Sealed Edges: Because laser cutting involves burning, the edges are always clean and sealed. This not only enhances the functionality of the finished product but also improves its appearance.

If you're in search of dependable laser cutting services, providers such as RazorLAB UK deliver the expertise and experience required. They utilize a fiber laser cutting machine, renowned for its speed, cost-effectiveness, safety, and precision. Whether you have intricate design needs or require precise cuts, opt for RazorLAB for laser cutting in materials like wood, acrylic, fabric, and card.

RazorLAB UK: A Leader in Custom Cutting Solutions

For those seeking specialised cutting services, RazorLAB laser cut company UK is a prominent player in the field. They're known for their commitment to delivering precision-cut components with exceptional quality. Using state-of-the-art CNC laser cutting technology, RazorLAB UK ensures that your project receives the attention it deserves.

The team at RazorLAB UK is dedicated to turning your design ideas into reality. Their modern equipment and skilled professionals allow them to cater to a wide range of needs, ensuring that your components are produced with accuracy and efficiency.

Whether you require intricate metal designs for industrial purposes or have a unique project in mind, RazorLAB UK's CNC laser cutting services can make it happen. They combine the precision of CNC technology with the flexibility of laser cutting to bring your ideas to life.

In conclusion, understanding the differences between CNC cutting and laser cutting is crucial when you need precise, custom-made components. CNC cutting relies on computer-controlled tools, offering versatility and speed, while laser cutting uses the power of heat for incredible precision and clean edges. Choosing the right method depends on your specific project requirements, and companies like RazorLAB UK stand ready to provide the high-quality cutting services you need to bring your designs to fruition. Whether you opt for CNC or laser cutting, you can rest assured that your components will be crafted with precision and expertise.

No comments yet