Are you looking for high-quality custom parts that are precisely milled to perfection? Look no further than CNC Milling, the premier provider of milling parts in various materials and sizes. In this article, we will explore why CNC Milling is the best choice for your custom parts needs.

Introduction to CNC Milling

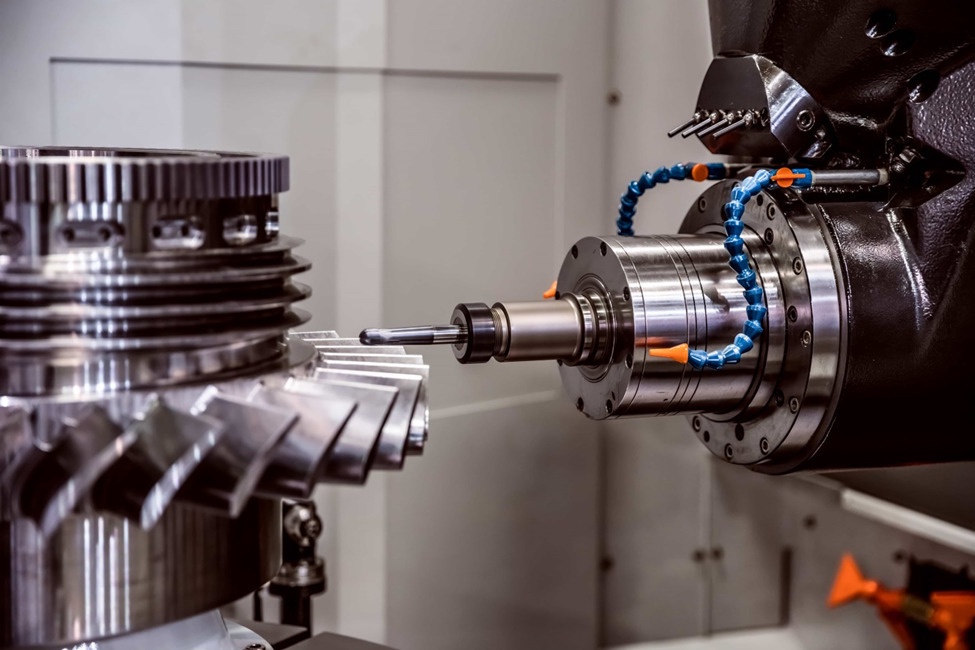

cnc milling suppliers is a process where computer controlled cutters remove material from a workpiece to create intricate shapes and designs. The process can be used to create parts in various materials, including metals, plastics, and composites. CNC Milling is an versatile manufacturing process that can produce small, complex parts with a high degree of accuracy.

The first step in CNC Milling is creating a computer model of the part to be milled. This model can be created using CAD software or by scanning an existing part. Once the model is complete, it is converted into a toolpath that the CNC machine can follow. The toolpath tells the machine what cuts to make and in what order to make them.

Once the toolpath is generated, the next step is to select the appropriate cutting tools. Cutting tools for CNC Milling are available in a variety of sizes and shapes to accommodate different materials and applications. The type of cutting tool and its geometry will determine the quality of the finished part.

After the cutting tools are selected, the material to be milled is loaded into the CNC machine. The machine then uses the cutting tools to follow the programmed toolpath and remove material from the workpiece. Depending on the complexity of the part, milling time can range from a few minutes to several hours.

CNC Milling is a versatile manufacturing process that can be used to create parts in a variety of materials and sizes. With proper

Benefits of CNC Milling Parts

There are many benefits to using CNC milled parts. The first is that CNC milling can produce very precise and accurate parts. This is due to the fact that the cutting tools used in CNC milling are very small and can be controlled very accurately. This means that parts produced using CNC milling will have very tight tolerances and will be of a high quality.

Another benefit of CNC milling is that it is a very versatile manufacturing process. It can be used to produce parts in a wide range of materials, from metals to plastics. This means that CNC milled parts can be used in a wide variety of applications and industries.

CNC milling also has a number of other advantages, such as being fast and efficient, having low set-up costs, and being able to produce complex shapes.

Choosing the Right Material for CNC Milling Parts

When it comes to CNC milling, the material of your part is just as important as its size. The type of material you use will determine the machining time, surface finish, and dimensional accuracy of your part. That’s why it’s important to choose the right material for your CNC milling parts.

There are a variety of materials that can be milled by CNC machines, including metals (steel, aluminum, brass), plastics (acrylic, polycarbonate), and composites (fiberglass, carbon fiber). Each type of material has its own unique properties that make it better suited for certain applications.

For example, aluminum is a popular choice for CNC milling because it is strong yet lightweight. It also has a low melting point, which makes it easy to work with. However, aluminum is not ideal for every application. If you need a part that is resistant to corrosion or extreme temperatures, you would need to choose a different material.

The best way to determine the right material for your CNC milling parts is to consult with an expert. At We Supply Milling Parts , we have over 20 years of experience in the industry and can help you select the perfect material for your project. Contact us today to get started!

CNC Machining Processes

CNC milling is a popular machining process in which a rotating cutting tool is used to remove material from a workpiece. The workpiece is secured to a table and the cutting tool is moved in various directions to create the desired shape.

There are three main types of CNC milling processes: horizontal, vertical, and face. In horizontal milling, the cutting tool is rotated about its horizontal axis. Vertical milling involves rotating the cutting tool about its vertical axis. Face milling involves moving the cutting tool across the face of the workpiece.

Each of these processes can be performed using either manual or computer-controlled equipment. Computer-controlled equipment is generally more precise and efficient than manual equipment, but it is also more expensive.

Types of CNC Milling Operations

Milling operations are generally categorized by the type of tool used. The most common types of tools are end mills, side mills, and face mills. End mills are used to remove material from the workpiece by cutting along the periphery of the workpiece. Side mills are used to remove material from the sides of the workpiece. Face mills are used to remove material from the top or bottom of the workpiece.

Cost Considerations for CNC Milling Parts

CNC Milling is a process that uses computer-controlled mills to remove material from a workpiece. The milling process can be done with a variety of different tools, including end mills and routers.

The cost of CNC Milling parts will vary depending on the specific project requirements. Some factors that can affect the cost include the type of material being milled, the size and complexity of the part, and the number of parts being produced. In general, CNC Milling projects will require a minimum investment to get started. However, once the initial investment is made, the costs associated with CNC Milling are typically very reasonable.

Quality Assurance for CNC Milling Parts

CNC Milling is a process that uses computer numerical control to machine parts from a workpiece. The process can be done with a variety of materials and in a variety of sizes. CNC Milling is a versatile manufacturing process that can produce parts with complex geometries and tight tolerances.

At We Supply, we take quality assurance seriously for all of our milling parts. We have a dedicated team of quality control inspectors who examine each part during and after production. Our inspectors use state-of-the-art measuring equipment to ensure that each part meets our high standards.

We also offer 100% inspection on critical features for customers who require it. We understand that quality is important to our customers, and we strive to provide the best products and services possible.

Conclusion

CNC milling is a great way to create precision parts with accuracy and speed. We provide an extensive range of CNC milling services that can help you get the exact parts you need, in the size, material, and style you require. Our experienced team has the knowledge and skills needed to ensure that your project is completed on time and within budget. Contact us today for more information about our CNC milling services - we look forward to hearing from you! Read More: YIJIN Hardware

No comments yet