The world of textile design is undergoing a remarkable transformation with the advent of direct-to-film fabric printing. This innovative technology is revolutionizing the way patterns, colors, and designs are applied to fabrics, allowing designers to unleash their creativity without limitations. Direct-to-film fabric printing eliminates the need for traditional methods like screen printing, bringing efficiency, precision, and endless possibilities to textile design. In this article, we will explore the various aspects of direct-to-film fabric printing and how it is shaping the future of textile design.

The Power of Direct-to-Film Fabric Printing

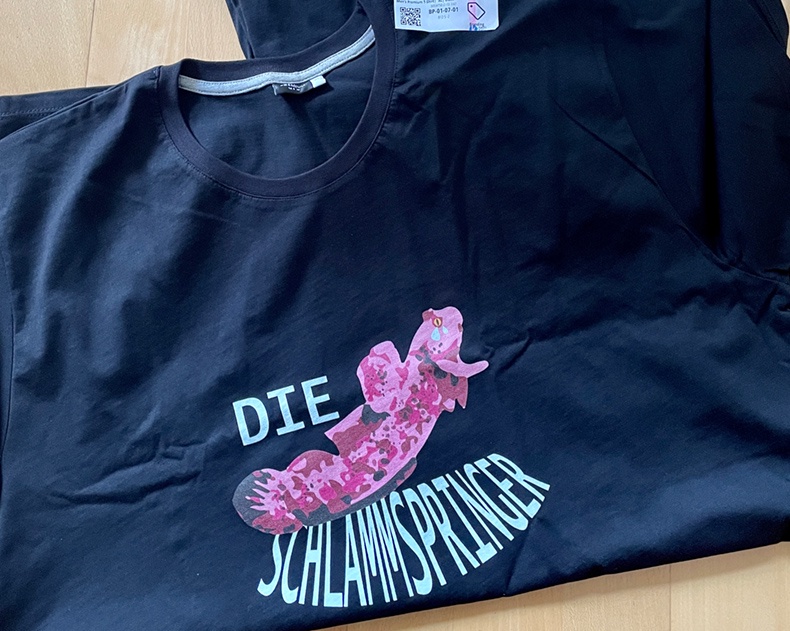

Direct-to-film fabric printing is a process that involves digitally printing designs onto a special film, which is then transferred directly onto the fabric. This method offers several advantages over conventional printing techniques. Firstly, it allows for intricate and highly detailed designs to be reproduced accurately on fabrics. This level of precision was previously unattainable with screen printing or other manual methods. Secondly, direct-to-film printing eliminates the need for multiple screens, thereby reducing setup time and costs. Designers can now bring their ideas to life more quickly and efficiently.

Endless Design Possibilities

With direct-to-film fabric printing, textile designers have a wide range of options at their fingertips. They can experiment with an extensive color palette, intricate patterns, and complex gradients that were once difficult to achieve. The digital nature of this technology allows for easy customization and personalization, making it possible to create unique designs for individual customers or specific collections. Additionally, designers can seamlessly incorporate photographs, illustrations, or even digital art into their fabric designs, enabling them to push the boundaries of creativity.

Sustainability and Environmental Benefits

One of the significant advantages of direct-to-film fabric printing is its environmentally friendly nature. Traditional printing methods often involve excessive water usage, harmful chemicals, and wasteful practices. In contrast, direct-to-film printing uses eco-friendly, water-based inks and produces minimal waste. The absence of screens and the elimination of manual color mixing also reduce the overall environmental impact. As sustainability becomes an increasingly critical aspect of the fashion and textile industries, direct-to-film fabric printing offers a greener alternative that aligns with the growing demand for eco-conscious practices.

Improved Quality and Durability

Direct-to-film fabric printing delivers exceptional quality and durability in the final product. The inks used in this process penetrate deep into the fabric fibers, resulting in vibrant and long-lasting prints. The colors remain vivid even after multiple washes, ensuring that the designs retain their original allure over time. Moreover, direct-to-film printing allows for precise registration of colors, meaning that intricate patterns and multicolor designs are rendered with utmost accuracy. This level of quality and durability opens up new possibilities for fashion designers, interior decorators, and textile manufacturers alike.

Conclusion

Direct-to-film fabric printing is reshaping the world of textile design by offering unrivaled creative freedom, sustainability, and superior quality. Designers are no longer bound by the limitations of traditional printing techniques but can instead bring their boldest ideas to life on fabric with unmatched precision. The technology's environmental benefits and ability to produce long-lasting prints make it a compelling choice for those seeking sustainable and durable solutions. As direct-to-film fabric printing continues to evolve, we can expect to see even more innovative applications and advancements in the world of textile design, cementing its position as a true revolution in the industry.

No comments yet