Introduction

In India, CNC milling has become a pillar of precision machining, revolutionizing the production environment across numerous industries. This guest post explores the world of CNC milling in India, highlighting the crucial roles that suppliers and manufacturers play in supplying high-quality components that satisfy international criteria. CNC milling is the key to producing intricate and precise parts for a variety of products, from aerospace to medical equipment, demonstrating India's proficiency in precision manufacturing.

Manufacturers Pioneering Excellence

There is a network of producers committed to quality and outfitted with cutting-edge technology at the center of the CNC Milling Suppliers. in India. These businesses are the backbone of the nation's precision machining industry, producing parts in accordance with worldwide certifications and standards.

- Cutting-edge technology

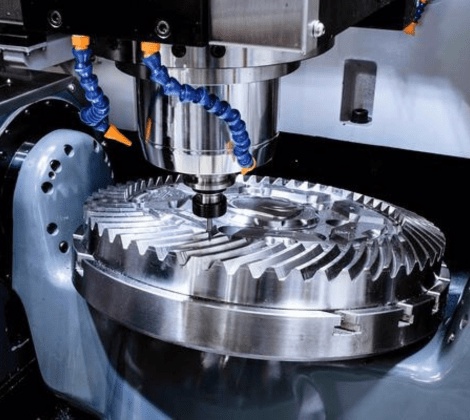

Indian CNC milling companies have made considerable investments in cutting-edge CNC equipment that can work with a variety of materials, including metals and polymers. When these machines are controlled by qualified specialists, complicated and complex parts can be produced with unequalled precision. The incorporation of cutting-edge software guarantees that every step of the production process is rigorously managed, producing components that are reliable and of a high caliber.

- Cost Effectiveness

The cost-effectiveness of working with Indian CNC milling manufacturers is one of the noticeable benefits. These firms can offer affordable pricing without sacrificing the quality of their goods thanks to India's competitive labor market. India is a desirable location for outsourcing CNC milling operations for companies looking to reduce manufacturing costs without compromising quality.

- Complete Solutions:

End-to-end solutions are frequently offered by Indian CNC milling manufacturers. This includes the entire process, from early concept and prototyping to component production at the end. Such integrated services shorten lead times and increase productivity by streamlining the production process. Customers can take advantage of a one-stop shop for all of their needs related to precision machining.

- Sustainable Development:

India has a large number of CNC milling producers who value sustainability. They use eco-friendly procedures in their business that reduce waste and energy usage. India is a favoured partner for eco-conscious companies because to its strong connection with international consumers who value sustainability in their supply chains.

The Unsung Heroes:

While CNC Milling Manufacturers get all the attention, India's CNC milling suppliers are just as important to the precision machining ecosystem. These suppliers act as a link between manufacturers and the equipment, supplies, and add-ons required for CNC machining operations.

- Thorough inventories:

Indian vendors of CNC milling offer big inventories that include all items required for precision machining. Cutting tools, workholding equipment, raw supplies, accurate measuring tools, and more are included. Their fully stocked warehouses guarantee that producers have access to a variety of goods, reducing production pauses and delays.

- Individualized Solutions

Indian vendors of CNC milling go above and beyond to comprehend the unique needs of enterprises. They provide specialized solutions that aid companies in streamlining their machining operations. These vendors make a substantial contribution to the efficiency of CNC milling operations, whether it be by making recommendations for the best cutting tools or by offering technical know-how.

- Prompt assistance and instruction:

CNC milling providers in India offer priceless services like technical assistance and training. They work directly with manufacturers, providing advice on how to run CNC machines efficiently. This proactive strategy increases overall machining productivity while simultaneously reducing downtime.

Indian CNC milling's benefits:

Numerous benefits make choosing CNC Milling India a desirable option for companies around the world:

- Technological Infrastructure and Skilled Labor:

India has a highly educated labor force and a strong technological foundation, which guarantee accuracy and quality in CNC machining processes. These resources are used by manufacturers to create complex components that adhere to global standards.

- Cost Effectiveness

The affordable labor market in India makes it a desirable location for outsourcing CNC milling jobs. Cost-effective solutions are available to manufacturers all around the world without sacrificing accuracy or quality.

- Speedy Turnaround:

The flexibility with which Indian CNC milling facilities complete projects on schedule is well known. The ability to respond to urgent demands and adhere to strict production schedules depends on this short turnaround time.

Conclusion

India has developed as a dynamic and trustworthy source for precision machining solutions thanks to CNC milling. Indian producers and suppliers are dedicated to providing premium components that satisfy international criteria. India is a top provider of CNC milling services thanks to their commitment to quality, efficiency, and sustainability. India's CNC milling industry is positioned to play an increasingly more vital role in providing excellence on a global scale as industries continue to seek high-precision components. Businesses looking to improve their precise machining capabilities can benefit from CNC milling in India, whether they're looking for top-tier manufacturing or a trustworthy supply chain partner.

Call us: +91 9657039991/(0253) 6646234

More about information for CNC Milling Manufacturers then Visit our site –

https://www.deccanew.com/cnc-milling-manufacturers-suppliers-india.php

No comments yet