The automotive industry stands as a testament to precision and innovation, with every component contributing to the overall efficiency and durability of vehicles. Among the many machining techniques employed, thread milling has emerged as a crucial method in crafting intricate and robust components.

Let’s look at the many applications of thread milling in automotive manufacturing, focusing on engine components, transmission parts, and critical fasteners.

The Automobile Industry and Thread Milling

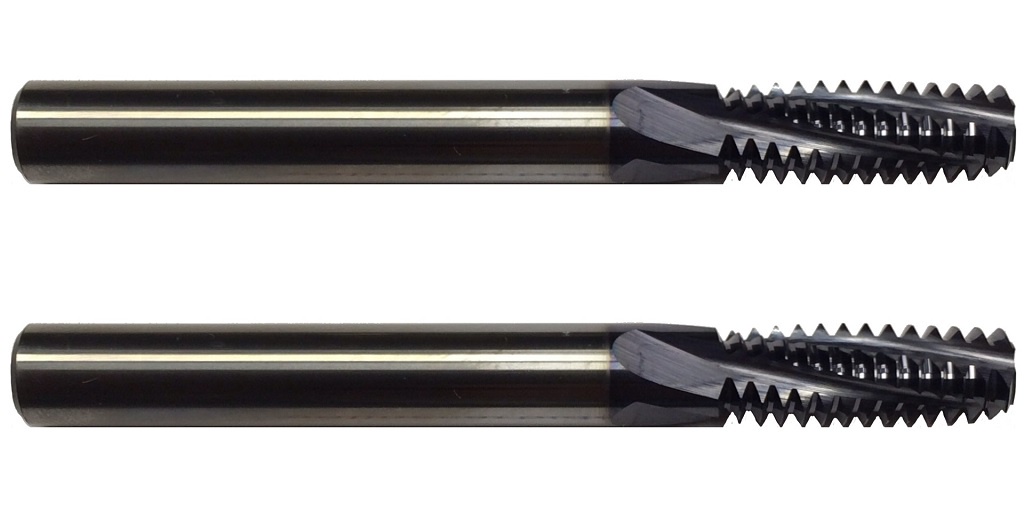

As vehicles become more sophisticated and demands for efficiency and durability rise, manufacturers in the automotive sector seek advanced machining techniques. Thread milling, a process involving specialized tools to create threads, has become an integral part of automotive manufacturing.

Its application extends across various components, with a notable impact on engine parts, transmission components, and critical fasteners. Using carbide thread mill NPTs (National Pipe Taper) in automobiles is a game-changer due to their exceptional durability, precision, and efficiency.

Carbide, known for hardness, ensures longevity in threading tools, reducing the need for frequent replacements. The precision of thread milling enhances the quality of threaded connections critical in automotive parts.

The efficiency of carbide thread mills accelerates production processes, contributing to overall manufacturing effectiveness. These advantages not only improve the reliability and performance of automobile components but also streamline production, making carbide thread mill NPTs a perfect choice in the automotive industry.

Engine Components

Cylinder Heads and Blocks

Thread milling plays a vital role in the creation of threads on cylinder heads and blocks. The precision offered by this technique ensures a secure fit for components, contributing to the overall efficiency of the engine.

Piston Rods and Crankshafts

The intricate threading on piston rods and crankshafts demands precision to maintain the structural integrity of the engine. Thread milling proves instrumental in achieving the necessary accuracy for these critical components.

Exhaust Systems

In the automotive world, where every element must function seamlessly, thread milling ensures the proper threading of exhaust system components. This is crucial for maintaining airtight connections and optimizing engine performance.

Transmission Parts

Gear Shafts and Gears

The transmission system relies heavily on precise threading for the smooth operation of gear shafts and gears. Thread milling provides the accuracy needed to ensure gear engagement and disengagement function flawlessly.

Clutch Components

Thread milling is applied to create threads on clutch components, enhancing their durability and reliability. The consistent threading ensures that these crucial elements perform optimally, contributing to the vehicle's overall drivability.

Differential Housings

In the manufacturing of differential housings, where strength and precision are paramount, thread milling proves to be a valuable technique. It ensures the creation of threads that can withstand the stresses associated with the differential system.

Critical Fasteners

Bolts and Nuts

Thread milling is extensively used in creating threads on bolts and nuts, the fundamental fasteners holding various automotive components together. The precision in threading contributes to the structural integrity and safety of the vehicle.

Studs and Screws

Critical fasteners like studs and screws undergo thread milling to meet specific torque and tension requirements. The accuracy in threading is essential for maintaining the stability of assembled components.

Wheel Hub Fasteners

Ensuring the safety and stability of a vehicle, wheel hub fasteners require precise threading. Thread milling guarantees the creation of threads that can withstand the forces exerted on wheels during vehicle operation.

Accurate Thread Milling Makes Your Vehicles Safe

Thread milling stands out as a cornerstone for achieving precision in the automobile industry. From engine components to critical fasteners, this technique plays a pivotal role in ensuring the efficiency and durability of vehicle parts.

For More Information About End Mills For Aluminum And Drill Mills For Sale Please Visit:- Online Carbide

No comments yet