PLA vs ABS: Heat Resistance Heroes

Introduction to PLA and ABS

PLA vs ABS, In the realm of material science, PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene) have emerged as pivotal players, dominating various industrial sectors. As sustainability becomes a pressing concern, the debate over PLA's eco-friendliness, durability, and cost-efficiency against ABS intensifies.

Properties of PLA and ABS

Density and Shrink Rate

PLA typically exhibits a density ranging from 1.25 to 1.28 g/cm3, with a shrink rate of 0.37-0.41%. On the other hand, ABS has a density between 1.05 to 1.18 g/cm3, with a shrink rate of 0.4-0.9%.

Melting Temperature

PLA's melting temperature ranges from 157 to 170°C, while ABS boasts a higher range of 217 to 237°C.

Tensile Strength and Young’s Modulus

PLA generally offers a tensile strength of 40-60 MPa and a Young’s Modulus of 1.7-3 GPa, whereas ABS provides a tensile strength of 27-52 MPa and a Young’s Modulus of around 2 GPa.

Heat Resistance Comparison

ABS demonstrates superior heat resistance compared to PLA. Over time, both materials degrade under sunlight or in moist environments.

Processing Methods

PLA Processing

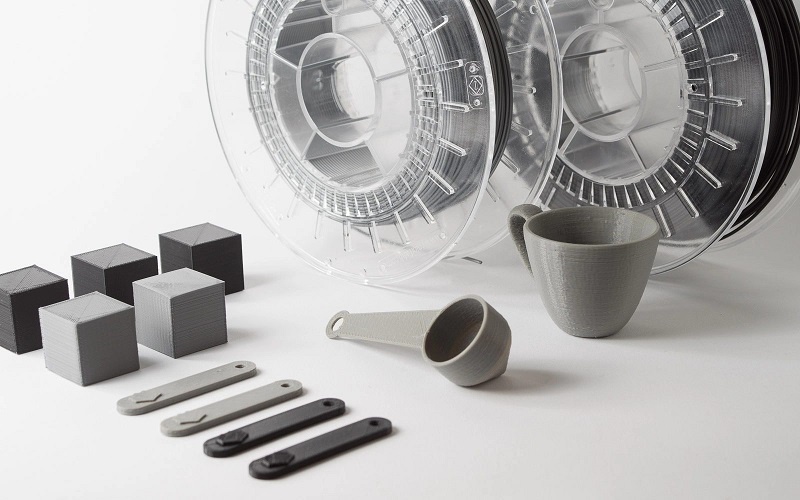

PLA is versatile and can be processed through various methods such as injection molding, extrusion, and spinning. It's particularly known for its excellent printing properties, making it a preferred choice for 3D printing.

ABS Processing

ABS, on the other hand, is suitable for processes like injection molding, extrusion, calendaring, and blow molding. It's widely used for industrial products and consumer goods requiring durability.

Pros and Cons of PLA

Advantages

- High transparency

- Antibacterial properties

- Biodegradability

- Safety

Disadvantages

- Poor heat resistance

- Higher price compared to ABS

Pros and Cons of ABS

Advantages

- Durability

- Heat resistance

- Easy to process

Disadvantages

- Warping tendency

- Fume emission during printing

Applications of PLA

PLA finds applications in biodegradable packaging, medical materials, and prototype manufacturing, owing to its unique properties.

Applications of ABS

ABS is extensively used in automotive parts, home appliances, mechanical components, and children’s toys due to its durability and heat resistance.

Conclusion

The choice between PLA and ABS depends on specific project requirements, including environmental concerns, strength, and heat resistance needs.

No comments yet