If you’re in the market for a new sewing machine, you may be wondering how a splicing machine works. After all, it’s an essential part of any sewing machine arsenal. In this blog post, we will explore the basics of splicing machines and what they can do for you. From repairing tears in fabric to creating seamless finishes, read on to learn more about this essential piece of equipment.

What is a Splicing Machine?

A splicing machine is a machine that is used to join two pieces of electrical wire together. The splicer will insert the two wires into grooves on the side of the machine, and then use clamps to hold them in place while the machine cuts the wires together.

How does a Splicing Machine work?

A splicing machine is a device that helps connect two pieces of film or video together. It does this by taking the two pieces of film or video, cutting them into small strips, and then stitching the strips together. This process is usually done using a tape splicer, but there are also machines that use a wire frame.

The first step in using a Splicing Machine is to bring the two pieces of film or video into the machine. The machine will then cut each piece of film or video into small strips and will place them on the crosshead. The crosshead is a movable part that helps guide the strips as they are stitched together.

image source: https://www.pinterest.ph

Once the strips have been placed on the crosshead, the machine will start stitching them together. This sewing process usually uses heat and pressure to hold the strips together. The machine will continue stitching until all of the strips have been connected. After connecting the strips, the machine will remove any excess fabric from around them and will then cut off the end of each strip.

Overall, a splicing machine is a very useful tool for connecting two pieces of film or video together. It can be used to fix various types of mistakes, and it is generally easy to use.

Advantages of using a Splicing Machine

A splicing machine is used to make quick, accurate repairs to cables using a heat and wire-woundsplicing technique. SpliceTek machines utilize a sophisticated algorithm that precisely coordinates the heating of the wires and the application of pressure to form a strong joint. This guarantees that no excess heat is applied which could potentially damage the cable or create flaws in the jacket.

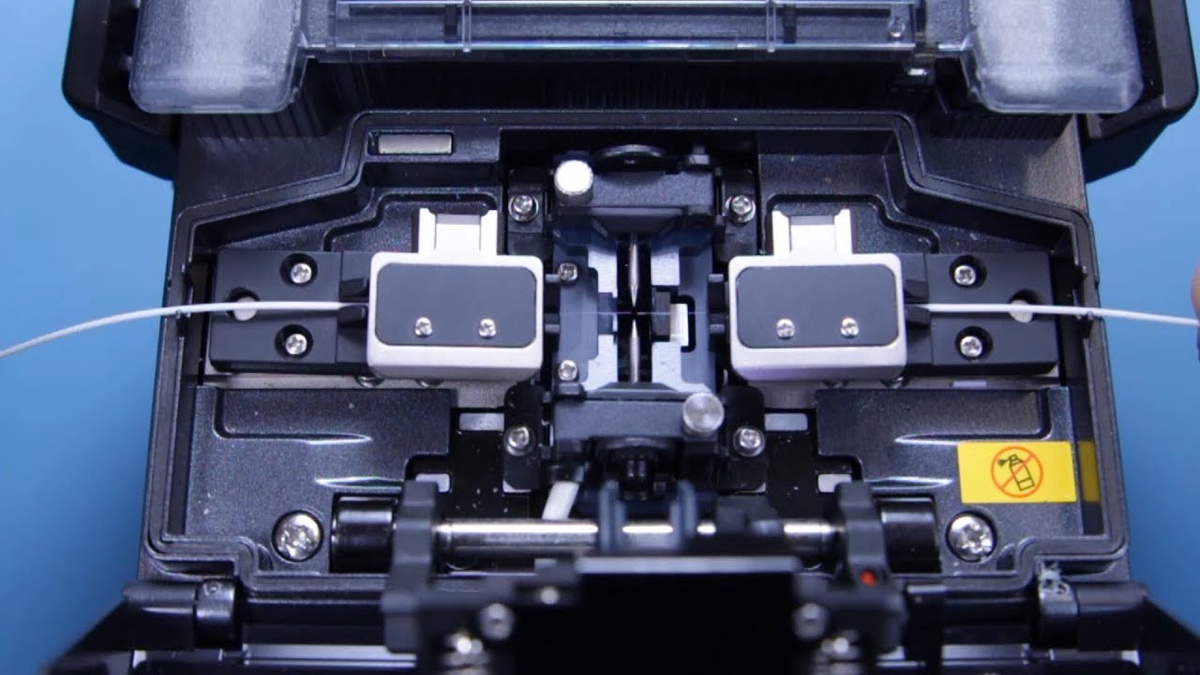

Another advantage of using a splicing machine that sometimes called as Fusion Splicer is that it can be used in difficult-to-reach areas, such as behind furniture or under carpets. This also means that repairs can be made quickly and without disruption to daily operations.

image source: https://www.pinterest.ph

Disadvantages of using a Splicing Machine

The main disadvantage of using a splicing machine is that it is time-consuming and requires a lot of skill to use. Additionally, it can be difficult to get the proper angle when splicing the wires together, which can lead to less-than-optimal results.

In addition, we have a a lot of choices that will be extremely beneficial and useful to those in the industry who require this additional information.

Here are some other products that are related: Fiber Stripper, Optical Talk Set and Live Fiber Identifier.

No comments yet