Embarking on the journey of selecting the ideal ribbon blender for your mixing requirements involves a careful consideration of various factors. This guide provides a step-by-step approach, offering insights into the key aspects to weigh when choosing a ribbon blender. Whether you're in the food industry, pharmaceuticals, or any other sector that requires efficient mixing, this guide aims to empower you with the knowledge needed to make an informed decision.

- Understanding the Basics: What is a Ribbon Blender?

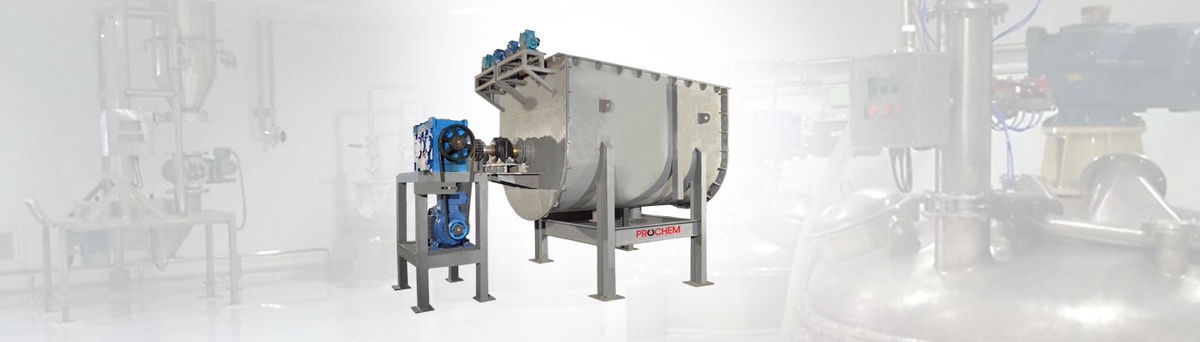

Begin your exploration by gaining a clear understanding of what a ribbon blender is and how it operates. Uncover the basic principles that define this versatile mixing equipment, including the design of the ribbon agitator and the container's shape. This foundational knowledge sets the stage for a more in-depth look into the features that differentiate various ribbon blenders.

- Types of Ribbon Blenders: Finding the Right Fit

Dive into the diverse world of ribbon blenders by exploring different types available in the market. From double ribbon blenders to paddle ribbon blenders, each type comes with its unique advantages and applications. This section guides you through the distinctions, helping you identify which type aligns best with your mixing needs.

- Considerations for Material Compatibility

One of the critical factors in choosing a ribbon blender is ensuring compatibility with the materials you'll be mixing. Delve into considerations related to material construction, finishes, and special features that may be necessary based on the nature of the substances involved. Learn how certain materials may prevent contamination or corrosion, ensuring the longevity and reliability of your ribbon blender.

- Capacity and Scale: Matching Your Production Requirements

Assess your production demands to determine the appropriate capacity and scale of the ribbon blender needed. This section offers insights into how the size of the blender impacts mixing efficiency, batch sizes, and overall productivity. By aligning the capacity with your operational needs, you can optimize your mixing processes.

- Customization Options: Tailoring the Ribbon Blender to Your Process

Explore the customization options available for ribbon blenders, allowing you to tailor the equipment to your specific process requirements. Whether it's adjusting agitator design, adding special features, or incorporating safety measures, understanding the customization possibilities ensures that the ribbon blender aligns seamlessly with your operational goals.

- Evaluating Manufacturers: Choosing a Reliable Partner

Navigate through the landscape of ribbon blender manufacturers, evaluating key criteria to identify a reliable and reputable partner. Consider factors such as industry experience, customer reviews, and adherence to quality standards. Choosing the right manufacturer is pivotal in ensuring the performance, durability, and support of your ribbon blender.

- Budget Considerations: Balancing Cost and Quality

Strike a balance between your budget constraints and the quality of the ribbon blender. This section provides insights into cost considerations, including factors that may influence the price of the equipment. By understanding the relationship between cost and quality, you can make a well-informed decision that aligns with your financial parameters.

- Installation and Maintenance: Ensuring Long-Term Performance

Explore the essential aspects of installing and maintaining your ribbon blender for optimal, long-term performance. From proper installation procedures to regular maintenance practices, this guide equips you with the knowledge to extend the lifespan of your ribbon blender and minimize downtime.

In conclusion, this comprehensive guide serves as your roadmap to selecting the right ribbon blender for your mixing needs. By combining fundamental knowledge, specific considerations, and practical insights, you'll be well-prepared to make a choice that enhances the efficiency and effectiveness of your mixing processes.

No comments yet