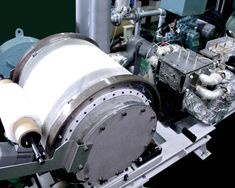

Metering pumps are critical components of a meltblown nonwoven machine. They are used to meter the melt, activate and deactivate the fiber extrusion. This article will demonstrate how to set up a metering pump in a Meltblown nonwoven machine.

Source: https://i.pinimg.com

What is a metering pump?

A metering pump is an essential piece of equipment in a meltblown nonwoven machine. It helps to measure the amount of melt that is delivered to the extruder and regulates the speed of the discharge.

What are the different types of meters?

Metering pumps are essential parts of a meltblown nonwoven machine. They are used to measure the melt, start and disable the fiber extrusion. This article will explain how to set up a metering pump in a Meltblown nonwoven machine. A metering pump is a necessary piece of machinery in a meltblown nonwoven machine. It aids in regulating the amount of melt given to the extruder and controls the discharge speed.

When setting your meltblown nonwoven machine to measure the resin, you must select a meter type that matches to the device used to manufacture the nonwovens. Flow rate meters can be used with meltblown machines that generate nonwoven fabric with slotted nozzles. Sensor meters work with machines that use piezoelectric sensors or touch sensors. Conductive meters can be used with machines that draw fiber from a reel to generate continuous nonwoven fabrics.

How to configure a metering pump in a meltblown nonwoven machine?

When installing your metering pump in a Melt Blown Nonwoven Production Line machine, there are a few factors to keep in mind. The most critical concern is that the pump can handle the amount of material that you will be processing. You will also need to calculate the proper flow rate for the kind of nonwoven fabric you are using. Finally, you must setup the metering system to precisely measure the amount of material being processed.

Setting up your metering system is quite simple once you've determined all of these things. All that remains is to configure the pump, flow meter, and controller. When everything is in place, you may start processing your materials!

Source:https://i.pinimg.com

Conclusion

In this article, we discussed how to configure a metering pump in a meltblown nonwoven machine. If you follow the recommendations and instructions provided you'll be able to maintain consistent levels of production and eliminate potential obstacles in operating your non woven making machine in the future. If you are insterested in the said machine, mind you that there are a lot of that in the internet and in the market. Some examples of these are Hydrophilic non woven fabric making machine, PP Spunmelt Non Woven Fabric Machine and pp spunbond non woven fabric machine.

No comments yet