The expression "water-driven frameworks" alludes to components utilized in the modern area to move power and control movement in an assortment of hardware and creation processes by utilizing the ideas of liquid mechanics. These systems usually create, regulate, and distribute hydraulic power through the cooperation of hydraulic fluid, pumps, actuators, valves, and other parts.

In simple terms, hydraulic systems employ pressurized fluid to perform functions like force-applying to shape or form materials, lifting large loads, and managing the motion of machines. Forging, stamping, metal shaping, material handling, machine tool operation, and automation are just a few of the many jobs they do in industrial settings.

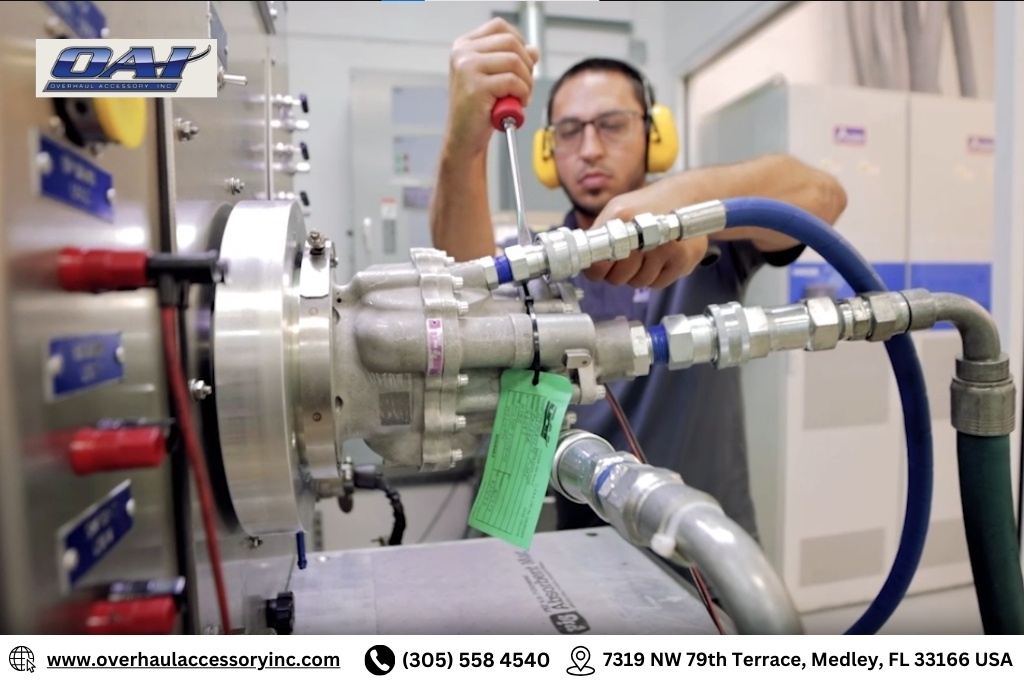

Most of the time, a pump drives hydraulic fluid through the system, putting pressure on a cylinder by way of connections, hoses, and control valves. The arm of a big pick-and-place robot or the ram on a model press, for example, moves as a result of the cylinder rod's conversion of hydraulic energy into mechanical energy.

Hydraulic drive systems offer a large number of important features and advantages, such as high torque production, correct control, variable speed capabilities, compact design, longevity, dependability, flexibility, and energy economy. Hydraulic drive systems provide operators with the ability to attain maximum efficiency, productivity, and operational effectiveness in their specific applications through the utilization of fluid mechanics concepts.

Benefits of using the hydraulic drive system

In the water, steam, sewage, paper, and petrochemical industries, as well as in dust gas, powdered fluid, powder solid medium transport equipment, and solution and manure two-phase mixed flow medium, hydraulic valves are extensively utilized.

There are several benefits of using the hydraulic drive system

- High-power density: High power output may be produced by hydraulic systems in a comparatively thick design. They are great for circumstances requiring a ton of force or when space is along with some hidden costs, as in large equipment or development gear, due to their powerful thickness.

- Precise control: Exact control: Precise activity of apparatus and gear is made conceivable by water-powered frameworks, which offer a similar command over turn, speed, and position. In manufacturing operations that need exact and repeatable motions, such as CNC machining and robotic applications, this precision control is crucial.

- Variable speed: By changing the hydraulic fluid's flow rate, hydraulic drive systems may readily reach different speeds. Machinery can accelerate and decelerate smoothly because of this flexibility, which also allows it to adjust to shifting operating needs.

- High torque at low speed: For applications requiring strong starting turns or heavy lifting, including material handling equipment and hydraulic presses, hydraulic systems are perfect because they can produce high turns at low speeds.

- Overload protection: To guard against system damage in the event of lavish load or pressure, hydraulic systems generally include relief valves or other overload safety features. This shields the machinery and its users from potential harm or mishaps.

Importance of hydraulic drive motor

As a crucial component for powering machinery and equipment, the hydraulic drive motor finds lavish use in both industrial and mobile applications. Several important factors underscore its significance, as follows:

- Powering machinery: For several industries to supply the mechanical power required to operate machinery and equipment, hydraulic drive motors are necessary. Industrial machinery, material handling systems, agricultural machinery, construction equipment, and more frequently employ them.

- High torque output: Particularly when operating at low speeds, hydraulic drive motors may produce large amounts of turns. This makes them especially ideal for large lifting applications or applications needing a high initial turn, such those found in cranes, bulldozers, and excavators.

- Precise control: The movement and functioning of machinery may be correctly controlled by operators thanks to the same speed, direction, and turn control provided by hydraulic drive motors. For jobs like those in robotic systems and CNC machining machines, which need for precise positioning and synchronization, this accuracy is essential.

- Variable speed: By varying the hydraulic fluid flow rate, hydraulic drive motors may happily obtain different speeds. The smooth acceleration, deceleration, and operation of machinery is made possible by this speed control flexibility, which may be adjusted to meet changing operating needs.

- Energy efficiency: Energy-saving designs and technologies, such variable displacement pumps and efficient hydraulic circuits, are incorporated into modern hydraulic drive motors to optimize energy consumption and lower running costs over time.

Conclusion

As per the above blog information with a number of advantages that add to its relevance and broad use, hydraulic drive systems are an important part of many industrial and mobile applications. If you have any doubts related to our service you can visit our website also.

No comments yet