Welding machines, the unsung heroes of metal fabrication, play a essential position in shaping the modern-day international. While bolting metals is an alternative, the versatility and strength completed thru welding are unprecedented. In this exploration, we delve into the makes use of of welding machines, highlighting the benefits and innovations brought approximately by using resistance welding machines specifically.

The Fundamental Role of Welding Machines:

Welding machines are vital gear for fusing materials, broadly speaking metals, to create structurally sound and seamless connections. The system includes making use of warmth, stress, or a mixture of both to soften and fuse the materials, ensuing in a bond that is frequently stronger than the base metals themselves. This ability to create crucial connections has some distance-accomplishing implications throughout diverse industries.

Applications of Welding Machines:

1. Construction Industry:

In production, welding machines are vital for joining structural components, reinforcing metal frameworks, and creating long lasting connections in homes and bridges. The capacity to precisely fuse metallic additives allows for the development of strong and strong structures.

2. Automotive Manufacturing:

Welding machines play a pivotal position within the automobile enterprise, where they're used to gather vehicle frames, exhaust structures, and numerous components. The precision and electricity executed via welding make contributions to the safety and toughness of vehicles.

3. Shipbuilding and Aerospace:

In shipbuilding and aerospace industries, welding machines are essential for creating complex and difficult systems. From assembling aircraft components to building hulls for ships, welding ensures the integrity and reliability of these high-stakes programs.

4. Manufacturing and Fabrication:

Across production sectors, welding machines are hired to manufacture a numerous range of products. From machinery and gadget to customer goods, the potential to weld metals provides producers with the ability to create diverse and customized products.

Welding vs. Bolting: The Strength of Fusion

While bolting metals together is a viable technique of becoming a member of, welding offers awesome blessings in phrases of strength, durability, and versatility. Bolting relies on mechanical connections, which might also loosen through the years due to vibrations, corrosion, or external forces. In assessment, welding creates a bond between the materials at a molecular stage, resulting in a connection that isn't always best stronger however also more proof against outside elements.

Resistance Welding Machines: A Technological Leap

1. Understanding Resistance Welding:

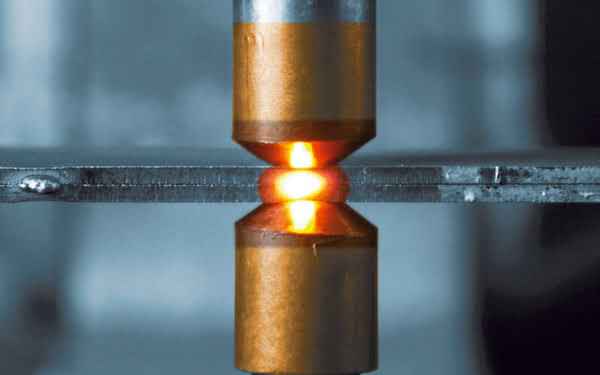

Resistance welding is a subset of welding that relies on the resistance to electric powered current to generate warmth for the welding procedure. This class consists of spot welding, seam welding, and projection welding, each tailor-made to specific packages. The splendor of resistance welding lies in its ability to create unique, localized bonds without the want for extra substances like filler metals.

2. Benefits of Resistance Welding Machines:

Efficiency and Speed:

Resistance welding machines excel in performance, imparting rapid heating and cooling cycles. This velocity is particularly positive in high-quantity manufacturing settings, wherein time performance is a critical element.

Consistency and Precision:

The automated nature of resistance welding guarantees constant outcomes, minimizing variations in the first-class of welded joints. The precision of the manner lets in for elaborate and dependable connections, assembly stringent enterprise standards.

Cost-Effectiveness:

While the initial funding in resistance welding machines may be better, their fee-effectiveness over time turns into obtrusive thru reduced material consumption, increased productivity, and minimized publish-welding processing necessities.

Environmentally Friendly:

Resistance welding produces minimum fumes and emissions compared to different welding strategies, aligning with contemporary environmental requirements. This element makes it an eco-friendly preference for resistance welding machine manufacturers aiming to reduce their carbon footprint.

Versatility in Materials:

Resistance welding machines may be used with lots of metals, such as steel, aluminum, and copper. This versatility makes them appropriate for a extensive variety of applications throughout diverse industries.

Innovations and Advancements:

The evolution of welding machines, particularly resistance welding technologies, has spurred innovations that pass past traditional packages.

1. Micro-Welding for Electronics:

Miniaturization in electronics demands precision welding on a microscopic scale. Resistance micro-welding has emerged as an answer for growing tiny connections in the manufacturing of electronic additives, contributing to the development of technologies together with microelectronics and scientific devices.

2. Automated Robotic Welding:

The integration of welding machines with robot systems has revolutionized manufacturing techniques. Automated robot welding complements performance, consistency, and safety via bearing in mind tricky actions and precise manipulate, further increasing the possibilities in industries including automobile production and aerospace.

3. Laser and Electron Beam Welding:

While resistance welding stays a staple, advancements in welding era have given upward push to laser welding and electron beam welding. These techniques provide unique blessings, which includes minimal warmth-affected zones and the capacity to weld distinct materials, beginning new frontiers in industries that call for present day answers.

Safety Considerations and Best Practices:

While welding machines empower industries with their abilities, it's critical to prioritize protection. Welding techniques contain excessive heat, doubtlessly risky fumes, and vibrant mild. Adequate schooling, proper protective tools, and adherence to safety protocols are paramount to make certain the well-being of operators and the integrity of the very last product.

Conclusion:

In end, welding machines stand as crucial tools which have formed the contemporary world thru their potential to create robust, durable connections amongst metals. While bolting is a feasible choice, welding offers unheard of strength and versatility. Within the world of welding, resistance welding machines, with their performance, precision, and environmental advantages, represent a technological jump that has revolutionized diverse industries.

As industries maintain to conform, so too will welding technologies, ushering in new opportunities and innovations. From building towering skyscrapers to crafting elaborate digital additives, welding machines, and the engineers in the back of them, remain at the vanguard of creating a related and resilient global. The adventure of these machines is not just about bonding metals; it is about forging the destiny with electricity, precision, and the spark of innovation.

No comments yet