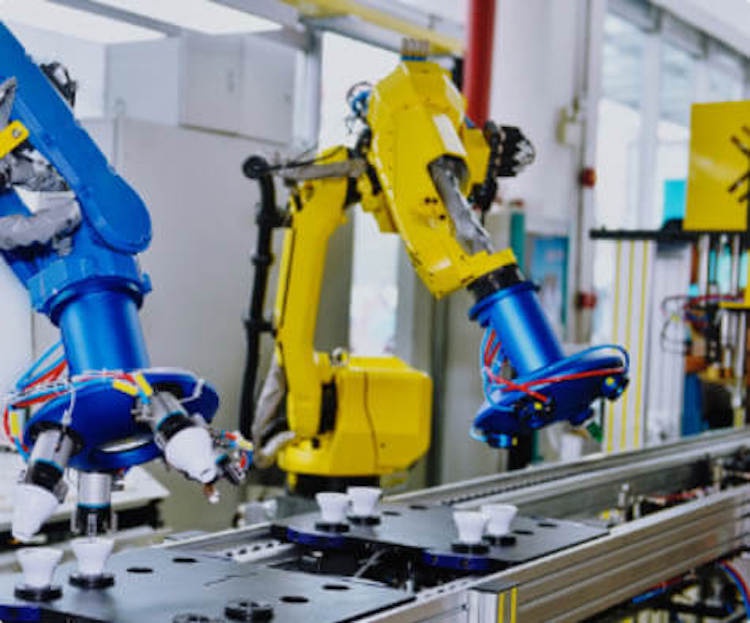

Robotics and automation are already widely used in injection molding and have significant advantages, just like in any other production process. This trend reflects a shift in mentality as more plastic injection molders use robots to outperform rivals. Without question, there has been a significant upward trend in the use of robots and automation in the processing of plastics.

Additionally, there is now a significant price reduction between standard injection molding equipment and that which has robotics integrated. At the same time, they have many advantages and are simpler to run, integrate, and program. The following sections will review the top benefits of an injection machine robot.

Perpetual Work

Injection molding is a repetitive procedure that helps produce the same or comparable goods with each injection. Injection molding robots offer the ideal option to prevent your personnel from being fatigued by this tedious activity, which could lead to errors at work or self-harm.

Robots assist in automating work and removing it from the hands of humans. This allows the business to continue producing its essential goods only with machines, concentrating its human workforce on driving sales and boosting income.

Return On Investment

End-users should choose a robotic injection molding solution for various reasons, including dependability, reproducibility, astonishing speed, multitasking capacity, and long-term cost benefits. A robot-equipped injection molding machine's capital cost is significantly more reasonable for many plastic component makers, which helps to support the investment's return.

The ability to produce continuously raises productivity and, as a result, the company's profitability. A single CPU in today's industrial robots will also be flexible enough to quickly adapt to a different product rather than being built for only one purpose.

Unparalleled Consistency

It is laborious to inject plastic into the molds manually. The molten liquids will typically not be evenly distributed when injected into the molds by an employee.

When you give this assignment to an injection machine robot, the outcomes will always be the same. The number of defective items decreases when robotics are used at practically every production level.

Multitasking

Robotic automation of your plastic injection molding process is also very cost-effective. Any other manual task in your company can be automated using the same robots you use for injection molding.

The robots can swiftly and successfully operate on various areas of the procedure with a well-planned schedule. When you don't need to change the arm tool ends, even the switch typically takes a short time. Give the robot a new command from your programming team, and it will continue to do the new mission.

Cycle Time

Cycle time is one of the critical components of the injection molding process; thus, automating it with robots will eliminate your cycle time concerns. The molds will always be evenly injected per your instructions if you program the robot to the necessary time intervals.

Final Words

It should be no surprise that robotic automation, including injection molding, offers many advantages. Injection molding manufacturers use robotics for various reasons, and you can be sure that this industry will continue to advance humankind.

At KEFAN Robot, they view product quality as the foundation of their business. They offer their clients a high-precision, high-speed, and high-stability injection machine robot. Integrity is the cornerstone of their business, and they take pride in their satisfied customers. They offer practical solutions per customer requirements.

No comments yet