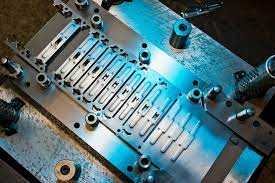

Efficiency is crucial in manufacturing, and custom tooling systems are the key. They improve production processes and deliver optimal results. Let's explore the benefits and transformative power of custom tooling systems.

*Increased Efficiency and Productivity

Custom tooling systems are tailored to your specific production requirements, increasing efficiency and productivity. Using tools designed for your unique applications can reduce cycle times, minimize tool changes, and streamline your machining processes.

*Enhanced Precision and Quality

Custom tools offer superior precision and quality compared to off-the-shelf solutions. You can achieve tighter tolerances, improved surface finishes, and better overall part quality by designing tools that precisely fit your application's requirements. This attention to detail will give you a competitive edge in the market.

*Cost Savings

While investing in custom tooling systems may seem like a high upfront cost, the long-term savings can be substantial. Custom tools often provide longer tool life, reduced tooling inventory, and lower maintenance costs. The efficiency and productivity gains can quickly offset the initial investment, resulting in overall cost savings for your company.

*Flexibility and Adaptability

In an ever-changing manufacturing landscape, having flexible and adaptable tooling solutions is essential. Custom tooling systems can easily accommodate design changes or new product introductions, ensuring that your production processes remain agile and responsive to market demands.

*Simplified Tool Management

Managing a diverse range of off-the-shelf tools can be challenging and time-consuming. Custom tooling systems streamline tool management by consolidating multiple devices into a purpose-built solution. This simplification reduces tooling inventory and eases tool maintenance and changeover tasks.

*Improved Process Control

Custom tooling systems allow for better process control and monitoring. You can more accurately track performance metrics by designing tools specifically for your applications, such as tool wear and cutting forces. This enhanced visibility enables data-driven decision-making, which leads to process optimization and continuous improvement.

*Reduced Downtime

Custom tools are designed to withstand the rigors of your specific machining processes, resulting in reduced downtime due to tool breakage or wear. With fewer unexpected tool failures, you can maintain higher production levels and keep your operations running smoothly.

*Competitive Advantage

Implementing custom tooling systems sets your company apart from the competition. By embracing innovative tooling solutions, you can increase productivity and reduce costs and demonstrate your commitment to excellence and innovation in your industry.

Custom Tooling Systems: The Final Verdict

Manufacturers are increasingly relying on specialized tooling solutions to help them improve production machining processes. The sector has grown enormously, and experts forecast it will continue to prosper.

Consider this scenario: Your company needs help to meet production quotas. Inefficient tooling leads to increased downtime and subpar part quality. Competitors with streamlined processes outpace you in the market.

Enter custom tooling systems – the solution to this dilemma. By embracing these systems, manufacturers can unlock the full potential of their production processes.

Benefits include:

- Increased efficiency and productivity

- Enhanced precision and quality

- Significant long-term cost savings

- Greater flexibility and adaptability

- Simplified tool management

- Improved process control

Manufacturers must invest in custom tooling systems to stay ahead of the competition. By doing so, they can optimize production machining processes and achieve unparalleled success.

No comments yet