Production machining is an essential part of your operation. The quality of your parts and fixtures can make or break your business. That’s why ensuring your manufacturing process is as efficient should be high on your list of priorities. One way to make that happen is through custom solutions. Learn how the art of customization and custom tooling solutions can shape the future of production machining and impact the growth and success of your business.

What is Custom Tooling?

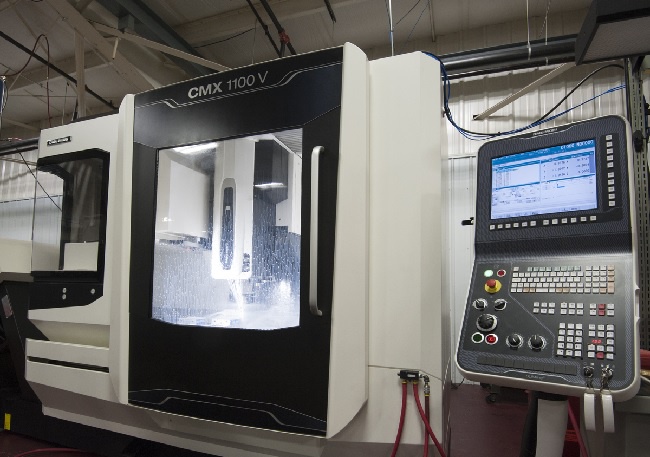

The term refers to the design and manufacture of specialized tools tailored to the specific needs of your business. Some companies achieve this by using computer-aided design (CAD) and computer-aided manufacturing (CAM) software, giving you results high on precision and accuracy. That’s one of the things you should look for before choosing a tool shop to create your tools and fixtures for production machining.

What are the Benefits?

Unique solutions: custom tooling allows you to create parts and fixtures unique to your business. With machine shop’s help to design and manufacture parts perfectly suited to your specific applications, you won’t have to worry about compromising on precision, quality or functionality. High levels of customization are often impossible with off-the-shelf tools since they aren’t designed to support those extra features. Custom solutions, on the other hand, are built to meet those standards. If you have specific operational needs, you’ll want to consider custom tooling and fixtures.

Optimize processes: Custom solutions allow you to optimize your manufacturing process. With tailored parts or fixtures, you reduce lead times and improve overall production efficiency. With tools perfectly suited to your production line, you can look forward to tool changes and manual adjustments. You also minimize errors or defects.

Reduce costs: Designing tools optimized for your specific needs allows you to cut down on any material waste. That also means much less need for repairs or rework, so you save more labor and material costs over time. All those factors help you improve your bottom line and stay competitive in a crowded marketplace.

Stay ahead: Custom tooling allows you to stay ahead of the curve in terms of technological advancements. Businesses that know how to leverage new technologies and manufacturing techniques are more likely to survive changes in the ever-changing business landscape. That’s one way to stay competitive. If you don’t want your competition to get the better of you, start working with a custom tooling shop that can provide the fixtures and tools you need. Check if they use the most advanced tools and techniques available in the industry.

Better quality: Working with a reliable modern tool shop gets you better quality parts and fixtures. That impacts the efficiency and speed of your production line. If you want your clients happy, get parts and tooling that you can trust.

Choose a tool shop with experience in custom tooling. Expertise and equipment in the design and manufacture of high-quality tools are also necessary. Look at the shop’s track record. Find one that is responsive and flexible, too.

No comments yet