Hydraulic power packs are a vital component in various industries, providing the force needed to operate machinery and equipment. In this comprehensive guide, we will delve into the world of reliable hydraulic power packs, exploring their inner workings, importance in different sectors, and the best practices for selecting, installing, and maintaining these powerful systems.

Understanding Hydraulic Power Packs

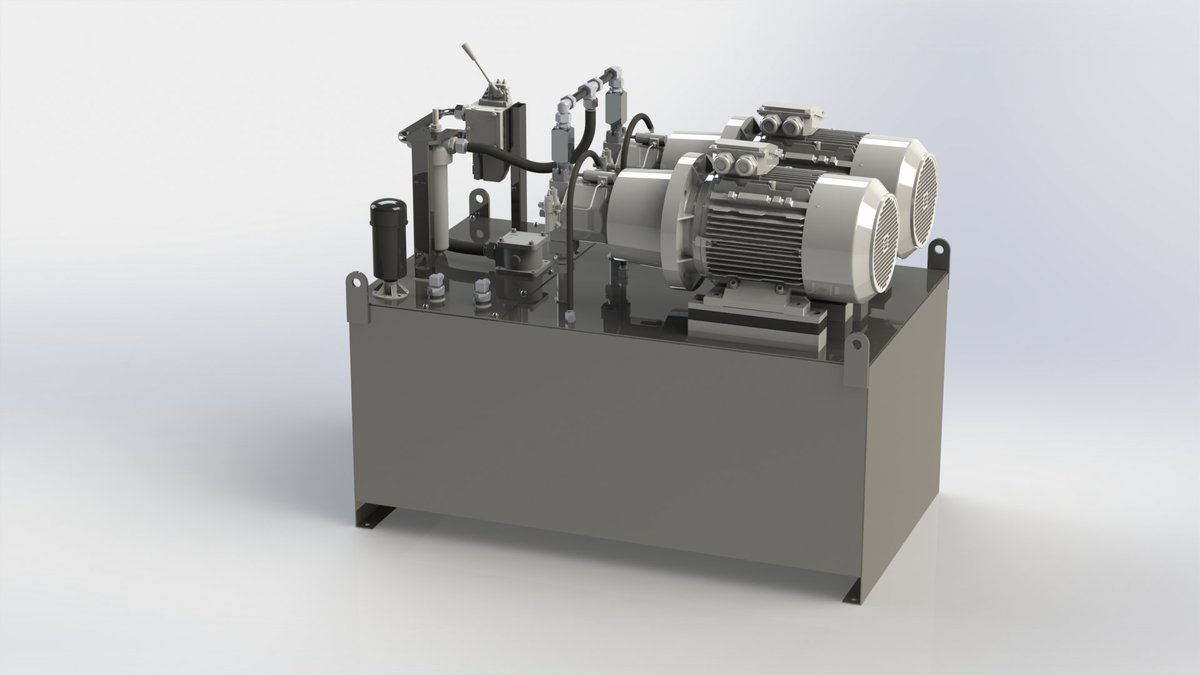

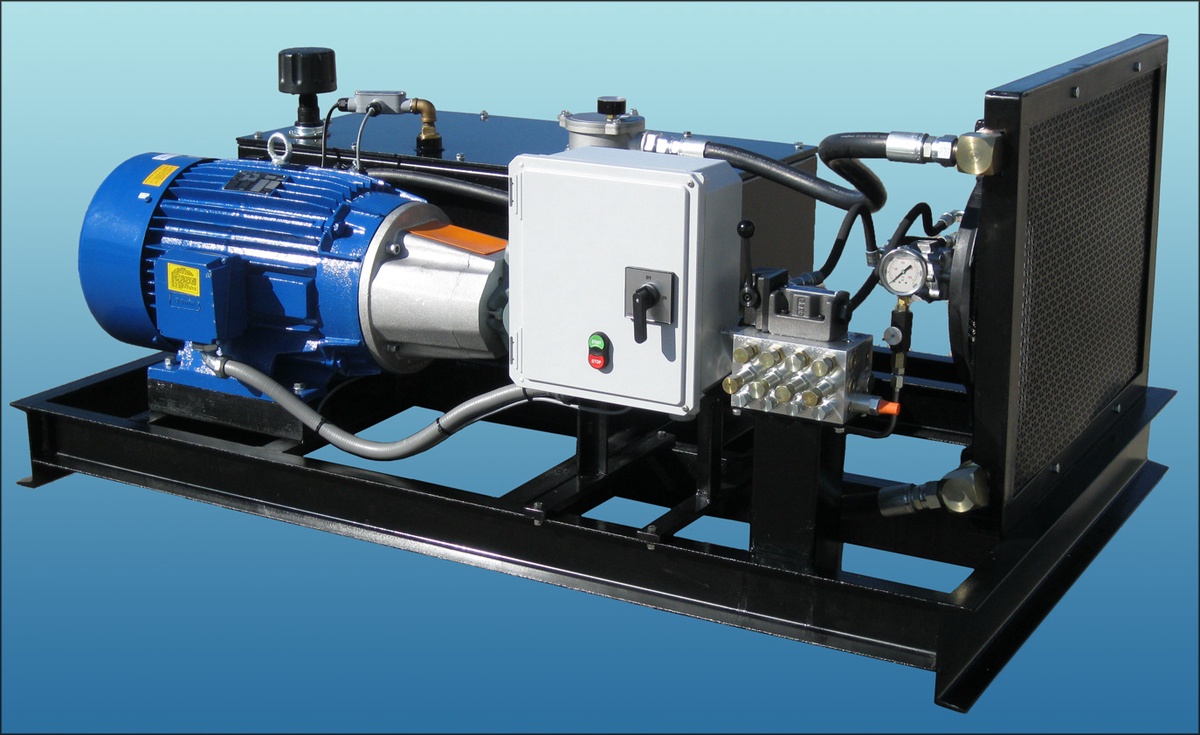

Hydraulic power packs are essentially self-contained units that consist of a reservoir, pump, motor, and control valves. These components work together to generate and control hydraulic power, which is then utilized to perform work in various applications.

The operation of hydraulic power packs revolves around the principle of Pascal's law, which states that when pressure is applied to a fluid in an enclosed system, that pressure is transmitted equally in all directions.

When the motor in the power pack activates, it drives the pump, which in turn pressurizes the hydraulic fluid. This pressurized fluid is then directed to the required components, such as hydraulic cylinders or motors, where it exerts force to perform the desired work.

There are different types of hydraulic power packs, each designed for specific applications. These include standard power packs, compact power units, and custom-built power packs tailored to meet unique operational requirements in industries such as construction, manufacturing, and agriculture.

Choosing the Right Hydraulic Power Pack

Selecting the right hydraulic power pack is crucial for ensuring optimal performance and efficiency in operations. Factors such as the required power output, flow rate, and pressure levels must be carefully considered to match the power pack to the specific application and equipment it will be driving.

By choosing the right hydraulic power pack, businesses can benefit from increased productivity, reduced downtime, and improved energy efficiency. Customizing the power pack to meet the exact demands of the machinery it operates will also contribute to prolonging the lifespan of the equipment and minimizing maintenance costs.

Installation and Maintenance Tips

Proper installation and regular maintenance are essential for the longevity and performance of hydraulic power packs. A step-by-step guide should be followed during installation, including mounting the power pack, connecting hydraulic hoses, and ensuring proper alignment of the components.

Regular maintenance procedures, such as checking fluid levels, inspecting for leaks, and replacing filters, should be carried out to prevent system failures and maintain the power pack's efficiency. Additionally, understanding common issues and implementing preventive measures is crucial for addressing potential problems before they escalate.

Safety Precautions and Best Practices

Safety is paramount when working with hydraulic power packs. Adhering to safety guidelines, such as wearing the appropriate personal protective equipment and understanding the risks associated with hydraulic systems, is imperative for preventing accidents and injuries.

Best practices for safe operation and maintenance involve proper training for personnel, conducting regular risk assessments, and implementing safety protocols in the workplace. By prioritizing safety, businesses can create a secure environment for their employees while ensuring the smooth functioning of hydraulic systems.

Advancements in Hydraulic Power Pack Technology

Recent technological advancements have led to significant improvements in hydraulic power pack technology. These advancements have focused on enhancing efficiency, reducing environmental impact, and increasing the sustainability of hydraulic systems.

The integration of smart technologies, such as IoT (Internet of Things) sensors and predictive maintenance algorithms, has revolutionized the monitoring and control of hydraulic power packs. These innovations enable real-time performance tracking, early fault detection, and timely maintenance, ultimately optimizing the operational efficiency of hydraulic systems.

Looking toward the future, trends in hydraulic power pack technology are expected to further enhance energy efficiency, incorporate renewable energy sources, and integrate advanced control systems for seamless automation and precision in operations.

Final Words

As we navigate through the intricacies of design and application, it becomes clear that hydraulic power packs are the unsung heroes powering our modern world. Whether you're a seasoned engineer or an enthusiast eager to harness hydraulic power packs, this comprehensive guide has laid the foundation for understanding and unleashing the potential of these remarkable systems.

Embrace the power, master the mechanics, and witness the impact of hydraulic innovation first-hand. The force is now in your hands.

Source: Power Unleashed A Comprehensive Guide to Hydraulic Power Packs

No comments yet