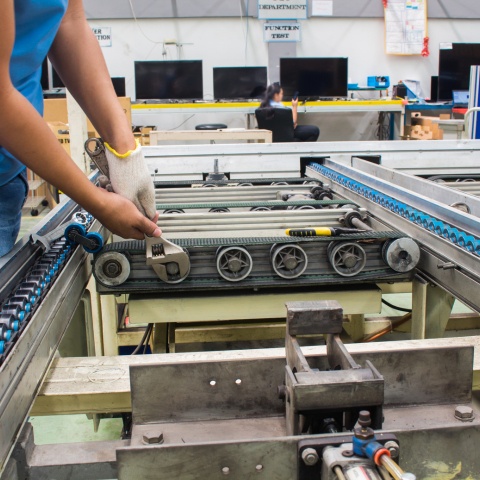

Conveyor belt systems are vital components in various industries, facilitating the seamless movement of materials and products. However, these belts are not immune to wear and tear, and occasional repairs are necessary to ensure uninterrupted operations. To effectively repair a conveyor belt, selecting the right tools is crucial. In this guide, we will provide you with pro tips on how to choose the best conveyor Belt Repair Tools for your specific needs.

1. Understand Your Conveyor Belt

Before selecting any repair tools, it's essential to have a thorough understanding of your conveyor belt. The first step is to identify the type of belt you're working with. Conveyor belts can be made of various materials, such as rubber, PVC, or metal. Each material requires different repair techniques and tools.

Next, assess the size and specifications of your belt. Measure its width and length, and take note of any unique features or components, such as cleats or sidewalls. Understanding your conveyor belt's specific characteristics will help you choose the right tools for the job.

2. Safety First

Safety should always be a top priority when working with conveyor belts. Ensure that the repair tools you select are designed with safety features in mind. Look for tools that offer ergonomic handles, non-slip grips, and safety guards to protect your hands and fingers during the repair process.

Additionally, consider personal protective equipment (PPE) such as gloves, safety glasses, and hearing protection. These items are essential to safeguard yourself and your team while working on conveyor belt repairs.

3. Quality Matters

Investing in high-quality tools is a smart choice when it comes to conveyor belt repair. Quality tools are not only more durable but also provide better results. Look for reputable brands and manufacturers known for producing reliable conveyor belt repair tools.

When assessing the quality of a tool, consider factors like the material it's made from, its construction, and any warranties or guarantees offered by the manufacturer. While quality tools may have a higher upfront cost, they often prove to be more cost-effective in the long run due to their longevity and performance.

4. Consider the Repair Type

The type of repair you need to perform on your conveyor belt will dictate the specific tools required. Common conveyor belt repairs include patching, splicing, and fastener installation. Each of these tasks demands specialized tools:

-

Patch Repair: For minor damages like cuts and tears, patch repair kits are essential. These kits typically include vulcanizing materials and tools such as a patch roller and cleaning solvent.

-

Splicing: Splicing tools are necessary for joining two conveyor belt ends together. Depending on the belt material and design, you may need hot vulcanization equipment or mechanical splicing tools.

-

Fastener Installation: If your conveyor belt uses fasteners for maintenance or repair, invest in a reliable belt fastener tool kit. Ensure it's compatible with the fastener type used on your belt.

5. Portability and Convenience

Consider the portability and ease of use of your chosen conveyor belt repair tools. Depending on your facility's setup, you may need to move tools to different locations along the conveyor system. Portable tools with carrying cases or easy-to-transport features can be a valuable asset.

Additionally, choose tools that are user-friendly and straightforward to operate. Complex tools may require extensive training and could lead to errors if not used correctly.

6. Maintenance and Support

Check if the tools you're considering come with proper maintenance instructions and support. Regular maintenance is crucial to extend the lifespan of your tools and ensure their reliability. Manufacturers that provide maintenance guidelines and readily available support can be a significant advantage.

7. Compatibility and Accessories

Ensure that the repair tools you select are compatible with your conveyor belt system. Some belts may have unique requirements or accessories that are essential for specific repair tasks. Double-check if there are any additional accessories or spare parts you might need to complement your tool kit.

8. Budget Considerations

While it's essential to prioritize quality and safety, it's also important to stay within your budget constraints. Evaluate the cost-effectiveness of the repair tools by considering their longevity and performance. Remember that investing in quality tools can lead to long-term savings by reducing downtime and the need for frequent replacements.

In conclusion, selecting the right conveyor belt repair tools involves a combination of understanding your specific conveyor system, prioritizing safety and quality, and considering the type of repair needed. By following these pro tips, you can ensure that your maintenance team is well-equipped to handle any conveyor belt repair job efficiently and safely, ultimately minimizing downtime and maximizing productivity in your facility.

No comments yet