As a brand that is revolutionizing the aerospace industry, Core Print Patterns is proud to introduce its cutting-edge solutions in plastic injection molding. With our unwavering commitment to innovation and excellence, we are setting new standards in the world of aerospace manufacturing.

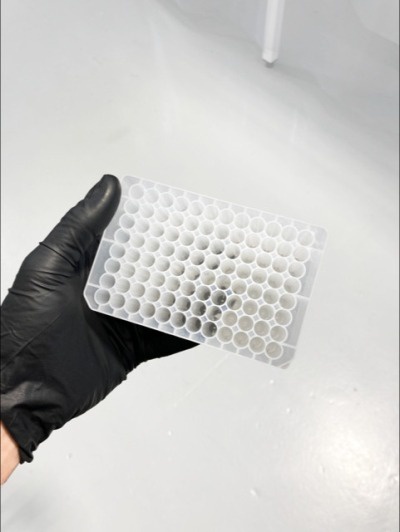

Plastic injection molding has long been a staple in manufacturing, and we have taken this technology to new heights with our innovative approach. As one of the leading plastic injection molding companies, we have honed our expertise in this field to deliver unmatched solutions for aerospace applications. Our state-of-the-art facilities are equipped with cutting-edge machinery and advanced techniques that enable us to produce highly complex and precise plastic components for aircraft, satellites, and other aerospace systems.

We thrive on pushing the boundaries of what is possible with plastic injection molding. Our team of engineers and technicians works tirelessly to develop innovative solutions to address the unique challenges of aerospace manufacturing. From light weighting to reducing part count, we employ advanced techniques such as over-molding, insert molding, and multi-shot molding to optimize the performance, durability, and reliability of our plastic components. Our creative and collaborative approach sets us apart from other plastic injection molding companies, allowing us to deliver breakthrough solutions for aerospace applications.

Our team understands that quality and reliability are paramount in aerospace manufacturing. We are committed to upholding the highest standards in every aspect of our plastic injection molding process. From material selection to rigorous quality inspections, we leave no stone unturned to ensure that our products meet or exceed industry requirements. Our team of experienced engineers and technicians follows strict protocols to ensure consistency, traceability, and repeatability in our manufacturing processes. We also conduct comprehensive testing and validation to ensure the performance and durability of our plastic components in the most demanding aerospace environments.

Innovation is at the heart of Core Print Patterns, and our research and development (R&D) efforts are a testament to that. We invest significantly in R&D to stay at the forefront of plastic injection molding technology and aerospace manufacturing trends. Our team of engineers and designers constantly explores new materials, processes, and technologies to enhance the performance and functionality of our plastic components. Through our commitment to continuous improvement and innovation, we aim to shape the future of aerospace manufacturing and lead the way in the industry.

We are a pioneering brand that is revolutionizing aerospace manufacturing through our innovative plastic injection molding solutions. We are proud to be at the forefront of shaping the future of aerospace manufacturing, and we look forward to partnering with our clients to unlock new possibilities and drive advancements in the industry. So, contact us today and let us be your trusted partner in unlocking the future of aerospace manufacturing. Together, we can achieve great heights!

John Luther is an author of this article.To know more about Plastic injection molding companies please stay with our website:coreprintpatterns.com

No comments yet