A hot air stove is required as the heat source for the rotary drum dryer. There is a chance of starting a fire while drying. due to the possibility that some burner sparks may enter the drum. Therefore, it is crucial to put out any sparks before they enter the drum. To address this issue, research has been conducted, and developed a design. In the section below, we use an example to demonstrate the process.

Wet material: lignocelluloses with a 45% moisture content, shaped as fluffy granules, with a bulk density of 512 kg per cubic meter; Dry materials must have a moisture content of 15% and must have a bulk density of 256 kg per cubic meter. Granules of lignocellulose with a diameter >3 mm and a moisture level of 15% are the stove's fuel. Numerous sparks will result from its air-driven combustion, which could be hazardous to the lignocellulose's drying process.

Therefore, the following two factors should be given extra thought when designing a combustion stove:

1. Fuel combustion effectiveness;

2. Sparks prevention techniques;

Due to the lignocelluloses being dried, the fuel's moisture level will be roughly 15%.

It is simple to ignite. And when there is an adequate supply of oxygen, the combustion is stable. Strong airflow will induce heat, which will then enter the rotating drum drier. A blower will be mounted on the stove to blast oxygen into the combustion chamber. Underneath the combustion chamber is the ash-settling area.

The stove's design allows for on-site customization. The sparks active prevention system uses established, dependable technology that is independent of any electrical components.

There’re two types of designs for sparks prevention:

1. Sparks settling channel

2. Sparks separating cyclones

Hot Air Stove

Ligno-cellulose has a calorific value of roughly 18.000 J/g in its operational stage with a water content of 14.5%. The stove's burning surface area must be 6 M2 to create 7 TPH of dry lingo-cellulose with a 15% moisture content. The stove's dimensions are 3000 mm long (5 pieces in the length direction) and 2040 mm wide (12 pcs of fire grates in the width direction).

The blower will be of the 3.2A-2.2Kw kind. The stove measures 3600mm long, 2780mm broad, and 2000mm high in total. There is a 100mm thick heat-insulating layer between the steel frame and the fire brick wall. The fuel-adding inlets will be on the sides of the stove due to their length. There are two inlets on either side, making it easier to add fuel and check the combustion.

Sparks Settling Channel

Sparks settling canal measures a total of 5140mm long, 1500mm wide, and 2000mm high. There is a 100mm thick heat-insulating layer between the steel shell and the fire brick wall. We build the system to contain 5 spark eliminating barriers to effectively eliminate sparks.

There is one air blow hole on each spark barrier. The barrier has a 260mm width. Every two barriers have a 500mm space in between them. Up and down, the air openings are uneven. As a result, the airflow will move in an "S" shape. There is a door to clear up the falling spark ash under each spark barrier. The fire bricks will be killed, fall to the ground, and turn into ash when the sparks strike them. A filter screen will be fitted on each air hole.

The Bottom Line

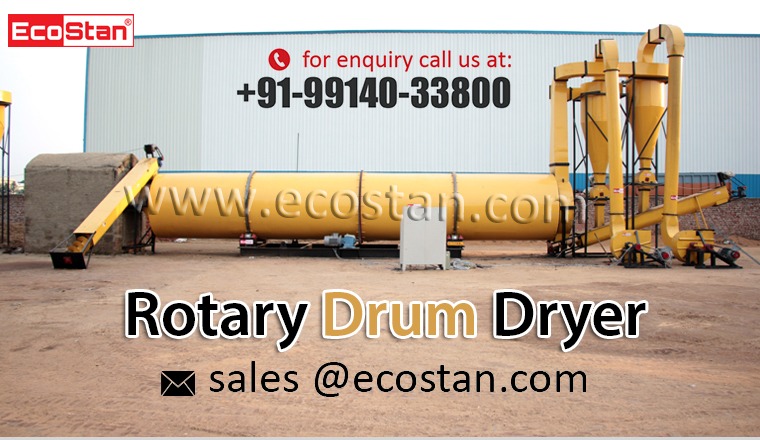

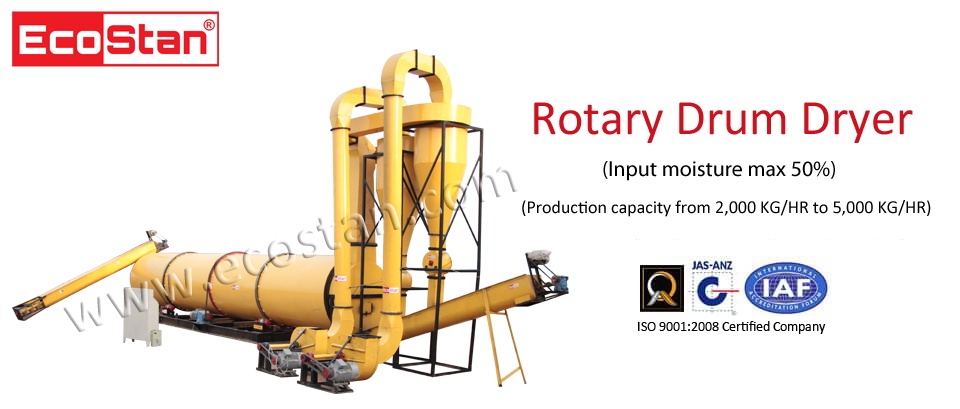

To get a high-quality Rotary Dryer, reach out to Ecostan where you will able to get robust briquetting machines at reasonable rates.

No comments yet