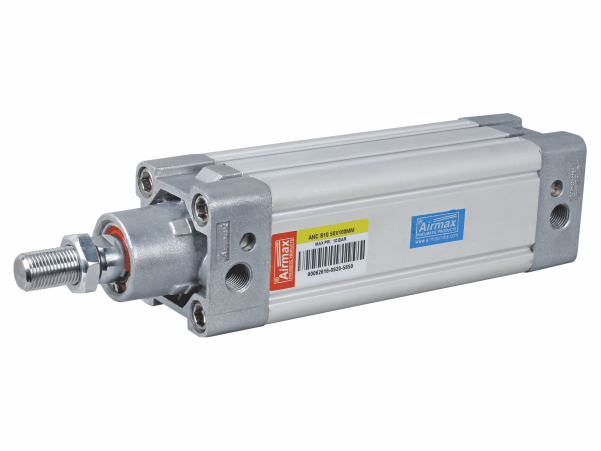

Double-acting air cylinders are workhorses in the automation industry, providing precise control and force in both extension and retraction strokes. Unlike single-acting cylinders that rely on springs for retraction, double-acting cylinders use compressed air on both sides of the piston for complete control.

- Bi-directional force: Apply force in both extending and retracting motions, ideal for pushing and pulling applications.

- Precise control: Compressed air allows for controlled movement and stopping at any point in the stroke.

- Faster operation: Air actuation on both sides enables quicker extension and retraction compared to spring-based systems.

- Versatility: Wide range of sizes, strokes, and mounting options to suit diverse industrial needs.

For reliable and efficient automation solutions in India, consider using high-quality double-acting air cylinders. When searching for these essential components, look for reputable suppliers offering "High Quality Double Acting Air Cylinders in India" to ensure durability, performance, and long-lasting operation.

Principles of Operation: How Double Acting Air Cylinders Work

Double acting air cylinders are vital components in various industrial applications, offering efficient linear motion control. Here's a breakdown of their principles of operation:

- Dual Action: Unlike single acting cylinders, double acting cylinders utilize compressed air to exert force in both directions—both extending and retracting the piston.

- Two Ports: These cylinders feature two ports—one for delivering compressed air to extend the piston, and another for exhausting air to retract it.

- Piston Design: Equipped with seals to prevent air leakage, the piston moves back and forth within the cylinder, converting air pressure into mechanical force.

- Versatility: Suitable for diverse tasks requiring precise and controlled movement, from manufacturing to automation.

- Maintenance: Regular inspection and maintenance ensure optimal performance and longevity of these cylinders.

For high-quality double-acting air cylinders in India, consider trusted manufacturers renowned for reliability and performance.

Components of Double Acting Air Cylinders: Piston, Cylinder, and Valves

High Quality Double Acting Air Cylinder in India is an essential component in various industrial applications, known for its reliability and efficiency. Understanding its key components is crucial for optimal performance:

- Piston: The piston is the main moving part of the cylinder, responsible for generating the force required for linear motion.

- Cylinder: The cylinder provides the housing for the piston and the space for compressed air to act upon it, facilitating movement.

- Valves: Double-acting cylinders feature valves that control the flow of compressed air into and out of the cylinder chambers, enabling both extension and retraction movements.

These components work together seamlessly to ensure smooth and precise operation of the double-acting air cylinder. When seeking a High Quality Double Acting Air Cylinder in India, considering the quality and durability of these components is paramount to achieving optimal performance and reliability in industrial processes.

The Role of Compressed Air in Double Acting Air Cylinder Functionality

In the realm of industrial machinery, the utilization of double-acting air cylinders plays a pivotal role in ensuring seamless operations across various sectors. Compressed air serves as the lifeblood of these cylinders, facilitating their functionality with precision and efficiency. Here's a breakdown of the crucial role compressed air plays:

- Power Source: Compressed air serves as the primary power source for double-acting air cylinders, providing the force necessary for both extending and retracting actions.

- Bidirectional Functionality: Compressed air enables the double-acting cylinder to perform tasks in both directions, enhancing its versatility and utility in diverse applications.

- Controlled Movement: By regulating the flow and pressure of compressed air, precise control over the movement of the piston within the cylinder is achieved.

- Reliability and Durability: The consistent supply of high-quality compressed air ensures the reliable and long-lasting performance of double-acting air cylinders.

For businesses seeking high-quality double-acting air cylinders in India, ensuring access to reliable sources of compressed air is paramount for optimal functionality and productivity.

Understanding the Directional Control of Double Acting Air Cylinders

Double acting air cylinders are crucial components in pneumatic systems, offering versatile motion control capabilities. Understanding their directional control is essential for efficient operation:

- Dual-Action Principle: Double acting cylinders utilize air pressure to extend and retract the piston, providing force in both directions.

- Directional Valve: Control of air flow is managed by a directional valve, directing pressurized air to either side of the piston for extension or retraction.

- Four Ports: Double acting cylinders typically feature four ports: two for air inlet/outlet during extension, and two for inlet/outlet during retraction.

- Reversal of Motion: Reversing the directional control valve switches the flow of air, causing the piston to move in the opposite direction.

- Applications: Widely used in industrial automation, machinery, and robotics for precise and controlled linear motion.

For reliable performance, invest in a high-quality double acting air cylinder in India, ensuring smooth operation and longevity of your pneumatic systems.

Exploring the Stroke Length and Force Output of Double Acting Air Cylinders

Double acting air cylinders are workhorses in automation, offering precise control in both extension and retraction strokes. But how do you choose the right one for your application? Let's explore two key factors:

- Stroke Length: This determines the distance the piston rod travels. It's crucial to match the cylinder's stroke length to your application's needs. Exceeding the stroke length can damage the cylinder, while a shorter stroke might limit your desired movement.

- Force Output: This refers to the maximum pushing or pulling force a cylinder can exert. Consider the weight and resistance of the object the cylinder will be actuating. Choosing a cylinder with insufficient force output can lead to stalling or incomplete movement.

By carefully considering these factors, you can ensure optimal performance and longevity for your double acting air cylinder. For high quality double acting air cylinders in India, trust reputable manufacturers who offer a wide range of options to meet your specific needs.

Different Types of Double Acting Air Cylinders: Tie-Rod, Roundline, and Profiled

Tie-Rod Cylinders:

- Consist of a cylindrical barrel with tie rods attached to each end.

- Commonly used in heavy-duty applications due to their robust construction.

- Ideal for applications requiring high pressure and load capacity.

Roundline Cylinders:

- Feature a smooth, round barrel design without external tie rods.

- Suitable for applications with space constraints as they offer a compact design.

- Often utilized in industries such as automotive, packaging, and material handling.

Profiled Cylinders:

- Have a unique barrel shape tailored to specific application requirements.

- Offer versatility and customization options for various industrial needs.

- Preferred for applications demanding precise control and positioning.

For high-quality double-acting air cylinders in India, consider exploring a range of options available in the market, including Tie-Rod, Roundline, and Profiled cylinders, to meet your specific application needs.

Applications of Double Acting Air Cylinders Across Industries

Double acting air cylinders find widespread usage across various industries due to their versatility and efficiency. Here are some common applications:

- Manufacturing: Used in automated production lines for tasks such as material handling, assembly, and packaging.

- Automotive: Employed in machinery for processes like stamping, welding, and painting.

- Construction: Utilized in equipment like hydraulic presses and lifting devices for construction projects.

- Aerospace: Integrated into aircraft systems for functions like landing gear operation and wing flaps.

- Mining: Applied in machinery for drilling, excavation, and material transport in mining operations.

- Marine: Used in ship equipment such as winches, cranes, and steering systems.

High Quality Double Acting Air Cylinder in India serves as a critical component in these applications, ensuring efficient and reliable performance across diverse industrial settings.

Advantages and Limitations of Double Acting Air Cylinders

Double acting air cylinders are the workhorses of pneumatic systems, offering precise control and reliable operation. But are they the right choice for your project? Let's explore the advantages and limitations:

Advantages:

- Bidirectional force: Apply force in both extending and retracting strokes, ideal for pushing and pulling actions.

- Precise control: Compressed air allows for smooth and controlled movement in both directions.

- Higher force: Achieve greater pushing and pulling force compared to single acting cylinders.

- Wide range of options: Benefit from a wider variety of bore and stroke sizes to meet specific application needs.

- ISO standards: Many double acting cylinders adhere to ISO standards, ensuring compatibility and ease of use.

Limitations:

- Air consumption: Requires a constant supply of compressed air, leading to potentially higher running costs.

- Leakage risk: Two air ports increase the possibility of air leaks, requiring proper maintenance.

- Cost: Generally more expensive than single acting cylinders due to their more complex design.

For high-performance applications requiring precise control in both directions, consider using high-quality double acting air cylinders in India. Explore the wide range of options available to find the perfect fit for your project.

Maintenance and Troubleshooting Tips for Double Acting Air Cylinders

Double acting air cylinders are workhorses in many industries. To ensure they operate at peak performance, regular maintenance and troubleshooting are key. Here are some quick tips:

- Lubricate Regularly: Apply lubricant to the piston rod, seals, and bearing surfaces according to the manufacturer's recommendations. This reduces friction and extends component life.

- Inspect for Leaks: Listen for hissing sounds and check for escaping air around the rod seal, piston seal, or fittings. Leaks indicate worn seals that need replacing.

- Filter Your Air: Contaminants in the air supply can damage seals and shorten cylinder life. Use an appropriate air filter to remove dust, moisture, and other particles.

- Monitor Rod Movement: Check for jerky or uneven movement, which can signal worn seals, misalignment, or excessive load.

By following these simple tips, you can keep your double acting air cylinders operating efficiently. For the highest quality double acting air cylinders in India, consult a reputable supplier who offers reliable products and expert support.

No comments yet