Magnetic air cylinders are innovative devices used in various industrial applications, offering efficient and precise control over linear motion. They utilize the power of magnets to provide smooth and reliable operation, making them ideal for tasks requiring accuracy and speed. Here's an overview of their features:

- Magnetic Force: These cylinders employ magnetic force for actuation, eliminating the need for traditional mechanical components like pistons and rods.

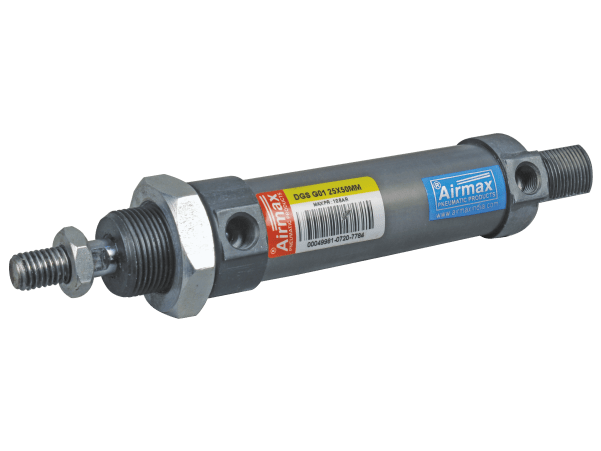

- Compact Design: Magnetic air cylinders boast a compact design, making them suitable for installations where space is limited.

- Versatile Applications: They find applications across industries such as automation, robotics, packaging, and more, enhancing productivity and performance.

- Customization Options: Manufacturers offer customization options to meet specific application requirements, ensuring compatibility and optimal performance.

When seeking the best magnetic air cylinders, turning to a trusted manufacturer is essential. As the top magnetic air cylinder manufacturer, we prioritize quality, reliability, and innovation in our products, catering to diverse industrial needs.

Basics of Pneumatic Systems and Their Components

Pneumatic systems utilize compressed air to perform various tasks, offering efficiency and versatility in industrial applications. Understanding the basics of pneumatic systems and their components is essential for efficient operation:

- Compressor: The heart of a pneumatic system, compressors convert power into potential energy stored in compressed air.

- Air Receiver Tank: Stores compressed air, providing a steady supply for pneumatic devices.

- Valves: Control the flow of compressed air, regulating pressure and directing it to desired components.

- Actuators: Convert compressed air energy into mechanical motion, commonly used in cylinders to generate linear motion.

- Filters, Regulators, and Lubricators (FRL): Ensure clean, regulated, and lubricated air for smooth operation and component longevity.

- Tubing and Fittings: Distribute compressed air throughout the system, connecting components securely.

Understanding these components is crucial for designing, installing, and maintaining pneumatic systems efficiently. For quality pneumatic components, consider sourcing from a top magnetic air cylinder manufacturer to ensure reliability and performance.

Understanding the Functionality of Magnetic Air Cylinders

Magnetic air cylinders are pneumatic actuators utilized in various industrial applications. They operate based on the principles of magnetism and compressed air.

Functionality:

- Magnetic air cylinders use magnetic force to move the piston within the cylinder.

- Compressed air is directed into the cylinder to create pressure, which in turn moves the piston.

- The magnetic force helps in controlling the movement and positioning of the piston precisely.

Applications:

- Commonly used in automated manufacturing processes for tasks such as gripping, pushing, and lifting.

- Found in industries like automotive, packaging, and robotics for their reliability and precision.

Advantages:

- Minimal friction, resulting in smooth operation and extended lifespan.

- Precise control over movement and positioning.

When seeking quality magnetic air cylinders, consider products from the top magnetic air cylinder manufacturer for optimal performance and reliability.

Advantages of Integrating Magnetic Air Cylinders in Pneumatic Systems

Traditional pneumatic systems offer reliable actuation, but they can be bulky and require precise alignment. Magnetic air cylinders address these limitations, bringing several advantages:

- Reduced Friction: Magnets replace traditional piston seals, minimizing friction and wear. This translates to smoother operation, increased efficiency, and potentially longer lifespans.

- Improved Cleanliness: Eliminating seals reduces the risk of contamination from lubrication, making magnetic cylinders ideal for cleanroom applications like food processing or electronics manufacturing.

- Higher Speeds: Lower friction allows for faster piston movement and cycle times, enhancing productivity in high-speed automation.

- Compact Design: Magnetic cylinders often have a smaller footprint compared to traditional options due to the simpler design. This saves valuable space, especially in tight machine layouts.

Considering integrating magnetic air cylinders? Partner with a Top Magnetic Air Cylinder Manufacturer to ensure you get the best performance and value for your application.

Key Components and Working Mechanisms of Magnetic Air Cylinders

Magnetic air cylinders offer a unique twist on traditional pneumatic cylinders. Here's a breakdown of their key components and working mechanism:

Components:

- Cylinder Bore: Houses the internal workings, similar to a traditional pneumatic cylinder.

- Piston: Moves within the bore, driven by compressed air.

- Magnetic Coupling: Replaces the physical rod connection between piston and external components. A powerful magnet on the piston interacts with...

- External Carriage: This carriage moves due to the magnetic force, eliminating the need for a rod seal, preventing air leakage.

Working Mechanism:

- Compressed air enters the cylinder, pushing the piston.

- The piston's magnet transmits this force through the cylinder wall to the external carriage via the magnetic attraction.

- The carriage's movement replicates the linear motion achieved in traditional cylinders, but with a completely sealed design.

This innovative design offers advantages like a clean, leak-free operation and reduced maintenance needs. To find a Top Magnetic Air Cylinder Manufacturer, consider factors like product range, customization options, and industry expertise.

Applications of Magnetic Air Cylinders in Various Industries

Magnetic air cylinders are revolutionizing automation with their unique blend of speed, control, and clean operation. These innovative actuators use magnetic fields to drive piston movement, offering distinct advantages over traditional pneumatic cylinders. Here's how they're making a difference:

- Manufacturing: Magnetic air cylinders excel in high-speed assembly lines, delivering precise positioning for delicate tasks. Their clean operation makes them ideal for dust-sensitive environments.

- Food & Beverage: The elimination of compressed air contamination risks makes magnetic cylinders perfect for food and beverage processing. Their fast response times ensure efficient production cycles.

- Electronics: The contactless actuation of magnetic cylinders minimizes particle generation, crucial for maintaining cleanliness in sensitive electronics manufacturing.

- Pharmaceuticals: Similar to food and beverage, magnetic cylinders safeguard sterile environments in pharmaceutical production. Their smooth operation minimizes vibration, ideal for sensitive equipment.

For superior quality and performance, look no further than Top Magnetic Air Cylinder Manufacturer. They offer a comprehensive range of magnetic cylinders to meet your specific application needs.

Challenges and Solutions in Integrating Magnetic Air Cylinders

Magnetic air cylinders offer a frictionless, clean alternative to traditional pneumatic designs. However, integrating them requires careful consideration of some unique challenges.

- Force and Stroke: Magnetic air cylinders typically generate lower force compared to pneumatic cylinders. Top Magnetic Air Cylinder Manufacturers can help with selecting the right size and design to achieve desired force within your stroke length.

- Air Gap Control: Maintaining a consistent air gap between the piston and the track is crucial for optimal performance. Specialized bearings and material selection can address this challenge.

- Sensor Integration: Unlike pneumatics, magnetic air cylinders lack inherent position feedback. Integrating magnetic position sensors or linear encoders ensures accurate control and monitoring.

By understanding these challenges and partnering with a reputable Top Magnetic Air Cylinder Manufacturer, you can successfully integrate this innovative technology into your next project.

Optimization Techniques for Efficient Performance in Pneumatic Systems

Pneumatic systems are workhorses in many industries, but even the best systems can be improved. By implementing a few key strategies, you can boost efficiency, reduce energy consumption, and extend component lifespans. Here are some top optimization techniques:

- Right-sizing is key: Ensure all components, from cylinders to piping, are sized correctly for your application. Oversized components waste energy, while undersized ones limit performance.

- Minimize leaks: Inspect hoses and fittings regularly for leaks, and consider using leak detection solutions. Even small leaks can significantly impact efficiency.

- Reduce friction: Shorten tubing runs and use smooth bends to minimize pressure drops.

- Control the pressure: Maintain the optimal pressure for each application using regulators. Don't rely on excessive pressure to compensate for inefficiencies.

- Embrace filtration: Proper filtration removes contaminants that can damage components and reduce performance. Choose the appropriate micron rating for your needs.

By following these tips, you can ensure your pneumatic system operates at peak efficiency. Remember, for the most advanced and efficient pneumatic solutions, consider partnering with a Top Magnetic Air Cylinder Manufacturer. Their expertise and cutting-edge technology can take your system to the next level.

No comments yet