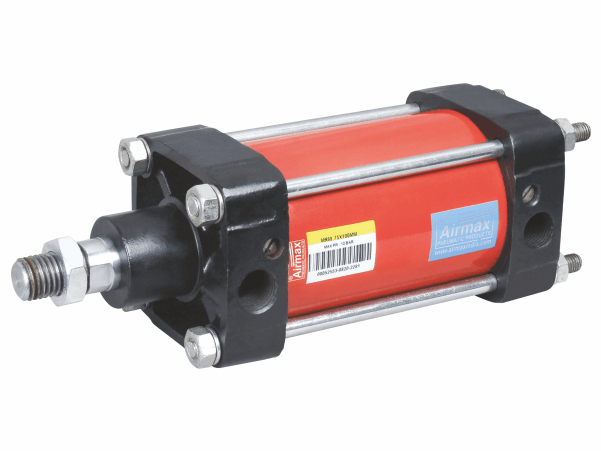

The Pneumatic cylinder plays a crucial role in both robotics and manufacturing industries, providing reliable and precise mechanical motion control. These devices, powered by compressed air, convert the potential energy of compressed air into linear or rotary motion, making them an essential component in various applications.

Here are some key points to understand the significance of pneumatic cylinders in robotics and manufacturing:

- Versatile motion control: Pneumatic cylinders offer a wide range of motion options, including linear, rotary, and even complex movements. This versatility makes them suitable for various robotic and manufacturing tasks.

- Quick and efficient operation: Pneumatic cylinders are known for their rapid response and high-speed operation. They can deliver fast and precise movements, enhancing productivity and efficiency in manufacturing processes.

- Robust and durable design: Pneumatic cylinders are built to withstand demanding industrial environments. They are designed to handle heavy loads, endure frequent usage, and withstand harsh conditions.

- Simple installation and maintenance: Pneumatic cylinders are relatively easy to install and maintain. They have fewer complex components compared to other motion control systems, making them cost-effective and user-friendly.

- Cost-effective solution: Pneumatic cylinders are often more affordable than their hydraulic or electric counterparts, making them a popular choice in robotics and manufacturing industries.

Overall, pneumatic cylinders provide reliable and efficient motion control, contributing to the success of robotics and manufacturing processes. Their versatility, quick operation, durability, simplicity, and cost-effectiveness make them a key component in various applications within these industries.

How Pneumatic Cylinders Enable Precise and Controlled Movement in Robotic Systems

Pneumatic cylinders play a crucial role in enabling precise and controlled movement in robotic systems. With their unique design and functionality, these cylinders provide several benefits that contribute to the overall efficiency and performance of robotic applications. Here are the key points to consider:

- Pneumatic cylinders are capable of generating high forces, allowing robots to perform tasks that require substantial strength and precision.

- The compressed air used in pneumatic cylinders provides a smooth and consistent power source, ensuring accurate and repeatable movements.

- By adjusting the air pressure and controlling the flow rate, operators can fine-tune the speed and position of the robotic arm or any other component equipped with a pneumatic cylinder.

- Pneumatic cylinders offer quick response times, enabling rapid and precise movements, which is especially crucial in high-speed robotic operations.

- These cylinders are lightweight and compact, making them ideal for applications where space and weight restrictions are a concern.

Overall, the utilization of pneumatic cylinders in robotic systems ensures precise, controlled, and efficient movement, making them an essential component in various industrial automation applications.

Enhancing Efficiency and Speed with Pneumatic Cylinders in Manufacturing Processes

Pneumatic cylinders play a crucial role in enhancing efficiency and speed in various manufacturing processes. Here's how they contribute to improving overall productivity:

- Rapid and Controlled Movement: Pneumatic cylinders provide quick and precise linear motion, allowing for fast and accurate positioning of components or tools. This reduces cycle times and increases throughput in assembly lines or production cells.

- High-Speed Operations: Pneumatic cylinders are capable of operating at high speeds, enabling fast and efficient operations such as material handling, part transfer, and packaging.

- Compact and Lightweight Design: Pneumatic cylinders are compact and lightweight, making them ideal for applications where space is limited. Their small size allows for efficient integration into machinery and automation systems.

- Simple and Reliable Operation: Pneumatic cylinders have a straightforward design and require minimal maintenance. They offer reliable and consistent performance, ensuring continuous production without significant downtime.

- Versatile Application: Pneumatic cylinders find application in various manufacturing processes, including machine tools, automotive assembly, electronics manufacturing, and more. They can be utilized for tasks such as clamping, pressing, lifting, pushing, and pulling.

By incorporating pneumatic cylinders into manufacturing processes, companies can experience improved efficiency, increased productivity, and enhanced speed, leading to higher overall output and profitability.

The Versatility of Pneumatic Cylinders in Robotic Arm Manipulation

- Pneumatic cylinders play a crucial role in robotic arm manipulation by providing reliable and precise movement capabilities.

- These cylinders utilize compressed air to generate linear motion, making them ideal for a wide range of robotic applications.

- The adjustable stroke length of pneumatic cylinders allows for flexibility in arm movements, enabling robots to perform various tasks with ease.

- Pneumatic cylinders are capable of exerting significant force, enabling robots to lift, push, and grip objects of varying sizes and weights.

- With fast response times and rapid actuation, pneumatic cylinders contribute to efficient and high-speed robotic arm operations.

- The compact and lightweight nature of pneumatic cylinders makes them suitable for integration into robotic systems without adding excessive weight or bulk.

- Pneumatic cylinders are easily controllable, allowing precise positioning and repetitive actions for consistent and accurate robotic arm manipulation.

- The durability and long lifespan of pneumatic cylinders make them suitable for continuous operation in demanding manufacturing environments.

- Pneumatic cylinders can be seamlessly integrated with other robotic components, enabling complex and synchronized movements for enhanced functionality.

- In summary, the versatility of pneumatic cylinders empowers robotic arms with the necessary motion capabilities to perform a wide range of tasks accurately and efficiently.

Safety Considerations and Benefits of Pneumatic Cylinders in Robotic Applications

Pneumatic cylinders play a crucial role in ensuring safe and efficient operations in robotic applications. Understanding the safety considerations and benefits associated with their use is vital. Here are some key points to consider:

Safety Benefits:

- Pneumatic cylinders provide reliable and precise actuation, minimizing the risk of accidents or injuries in robotic operations.

- They offer quick response times, allowing for immediate stops or reversals when necessary, enhancing overall safety.

- Pneumatic systems are inherently safe due to their compressed air power source, reducing the risk of fire or electrical hazards.

Considerations for Safety:

- Proper installation and maintenance of pneumatic cylinders are essential to ensure their safe operation.

- Implementing safety measures such as pressure relief valves and safety guards can prevent potential risks.

- Regular inspections and monitoring of pneumatic systems can detect any faults or leaks that may compromise safety.

- By prioritizing safety and harnessing the benefits of pneumatic cylinders in robotic applications, manufacturers can create a secure and efficient working environment.

Pneumatic Cylinder Integration in Assembly Line Automation

In the realm of assembly line automation, pneumatic cylinders play a vital role in ensuring smooth and efficient operations. These versatile devices are commonly utilized to facilitate precise movements and actuation in various stages of the assembly process. Here are some key points highlighting the integration of pneumatic cylinders in assembly line automation:

- Pneumatic cylinders provide reliable linear motion control, allowing for precise positioning and alignment of components.

- They enable fast and repetitive movements, contributing to enhanced production speeds and throughput.

- By incorporating pneumatic cylinders, automated assembly systems can perform tasks such as gripping, pushing, lifting, and rotating objects with ease.

- The compact and lightweight nature of pneumatic cylinders makes them suitable for integration into tight spaces and portable automation systems.

- Pneumatic cylinders are compatible with various control systems, allowing for seamless integration into existing assembly line setups.

- Their robust design and durability ensure long-term reliability, minimizing downtime and maintenance requirements.

Overall, the integration of pneumatic cylinders in assembly line automation brings efficiency, accuracy, and flexibility to the manufacturing process, ultimately contributing to improved productivity and product quality.

Improving Productivity with Pneumatic Cylinder-Based Pick-and-Place Systems

- Pneumatic cylinder-based pick-and-place systems play a crucial role in enhancing productivity and efficiency in various manufacturing industries.

- These systems utilize pneumatic cylinders as actuators to precisely pick up objects and place them in desired locations.

- The use of pneumatic cylinders offers several advantages, such as fast and reliable operation, compact design, and cost-effectiveness.

- Pneumatic cylinder-based pick-and-place systems can handle a wide range of objects, including small components, boxes, and even heavy objects, depending on the cylinder's capacity.

- These systems can be easily integrated into existing manufacturing processes, allowing for seamless automation and reducing manual labor.

- The speed and accuracy of pneumatic cylinders enable rapid and repetitive tasks, resulting in increased production rates and improved overall productivity.

By eliminating human errors and fatigue associated with manual pick-and-place operations, pneumatic cylinder-based systems ensure consistent and precise positioning of objects. The simplicity of pneumatic cylinder-based pick-and-place systems facilitates easy maintenance and troubleshooting, minimizing downtime.

No comments yet