Centrifugal chemical pump engines are used for a variety of industrial applications, including the manufacture of chemicals, polymers, and other products some example of these are magnetic drive pump and slurry pump. This engines are very important in the industrial work and if not used properly, these engines can fail. In this post, we'll look at the primary causes of centrifugal chemical pump engine failure and how to avoid them.

The basic principles of a Centrifugal Chemical Pump Engine

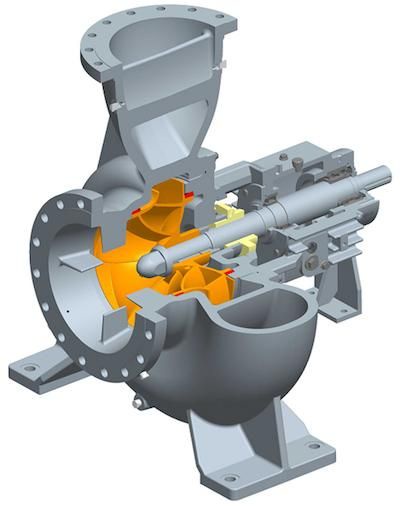

A centrifugal chemical pump engine is a type of internal combustion engine that uses a rotating impeller to move fluid. These engines are used to transfer chemicals and other substances between different parts of a plant. They can be either single or twin shaft engines.

Wear and tear on the moving parts is one of the leading causes of centrifugal chemical pump engine failure. Factors such as wrong assembly, poor maintenance, and misuse can all contribute to this. It is critical to keep the engine functioning efficiently so that it can last for a long time.

image source: www.pinterest.ph

The main causes of the breakdown of Centrifugal Chemical Pump Engines

Wear and tear, overload, defective design or construction, and wrong use are the most common causes of centrifugal chemical pump engine failure. The frequent cycling of the engine causes wear and tear, whereas overload can be produced by faulty operation or the addition of too much weight to the machine. Faulty design or production can arise when engine parts are not correctly put together or when the materials used are subpar. Finally, improper use may involve improper oiling and maintenance practices.

All of these conditions can cause an engine failure, resulting in decreased performance and possible equipment damage. As a result, it is critical to take preventive steps on a regular basis to ensure that your centrifugal chemical pump engine remains in good operating condition. Regular inspection and maintenance, as well as the use of certified lubricants and replacement parts, are among these precautions.

image source: www.pinterest.ph

How can the breakdown of a centrifugal chemical pump engine be prevented?

Many problems might cause a centrifugal chemical pump and slurry pump engine to fail, but the most prevalent are wear and strain on the pump components, lack of lubrication, and contamination. To avoid this, it is critical to keep your engine running smoothly and at peak performance. Here are some pointers to keep your chemical pump in good working order:

1. Regularly inspect the quality of your engine parts and replace any worn or broken components. This will assist to reduce wear and tear, which can lead to engine failure.

2. Use a quality oil made specifically for pumps to keep your engine lubricated. Inadequate lubrication might also cause the engine to break down.

3. Keep your engine clean by using a degreasing chemical to clean all sections of the engine on a regular basis. Contamination can potentially cause an engine to fail.

No comments yet