What exactly is the Production Process for Forged Blocks?

Forged blocks are used in various industries to provide purposes that are different. They are made through a complex process of forging, which involves heating and shaping materials like metal to create a solid, durable block. , we will explore the production process of forged blocks, its benefits, use, and value in different industries.

The Production Process of Forged Blocks:

Forged blocks are made using a process that try specific as drop forging. The process involves heating the metal to a temperature this is certainly shaping that is high with a hammer. The process creates blocks that are tougher and have greater strength levels because the structure this is really internal of metal is aligned. Here are the steps involved in the production of forged blocks:

1. Selecting Materials: The forging block process begins by selecting the materials that are right the blocks. It involves the utilization of high-quality metals like alloy steel, carbon steel, stainless steel, and more materials that meet industry criteria.

2. Heating: The metal try heated to a temperature this is really specific allows the material to soften enough to feel molded. High temperatures make the metal malleable and easy to shape.

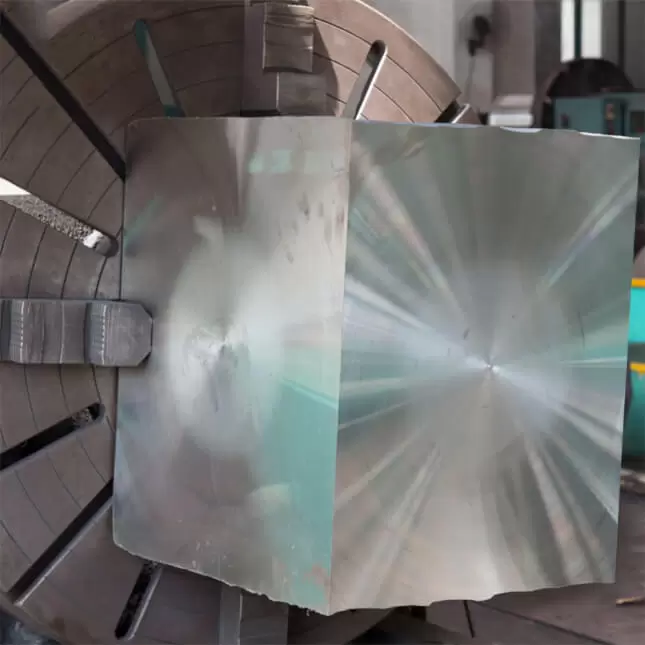

3. Shaping: Once the temperature is reached by the metal which was true it is put on a press this is certainly forging shaped into the desired block shape. The press exerts an amount that is enormous of on the metal to create the block shape.

4. Machining: After shaping, the block undergoes further machining to remove any materials that are excess give it a finish this is actually fine.

5. Testing: The forged block undergoes testing to ensure that it meets industry standards.

Popular features of Forged Blocks:

Forged blocks have several advantages that produce them the choice which was preferred applications that are various. Right here are a handful of the plain things that are great using blocks that are forged

1. Durability: Forged blocks are very durable and can withstand conditions that are harsh degrading or deteriorating.

2. Strength: Forged blocks has a higher power level because their structure it was certainly internal ended up being. This decrease the potential for breakage due to forces that are external.

3. Precision: Forged blocks and Monel 400 Forged Block undergo thorough testing to make sure that they are of the quality this is certainly highest and meet industry standards. Therefore, they give you a level that is known was high for this ensures effectiveness in their usage.

4. Resistance: Forged blocks are resistant to wear and tear, corrosion, and more types of harm that can take place in harsh environments.

Innovation and Safety:

Innovation was critical to forge blocks that are high-quality. Manufacturers are constantly working to develop techniques are new enhance the quality, reliability, and durability of forged blocks. Safety are also a component this is certainly definitely critical the production process. Manufacturers always ensure they fulfill safety standards to make sure that users are safer when using the blocks. Proper maintenance and use of the blocks are crucial to safety.

How to Utilize Forged Blocks:

Forged blocks have different applications in industries like construction, automotive, and oil and gas companies. They are used as:

1. Structural materials in buildings and bridges.

2. Assemblies in vehicle engines and other parts that are going.

3. Machinery components in the manufacturing industry.

4. Tools and equipment for drilling and other processes that are industrial.

5. aids for pipelines and other infrastructure.

When using forged blocks, it's important to consider the size, shape, and material used. Its also necessary to make sure the blocks meet industry standards and requirements.

Service and Quality:

Manufacturers of forged blocks offer various services to be sure that their customers get the quality blocks that are best. They offer consultation services to assist clients choose the right blocks for their applications. They offering repair and maintenance services to make certain the blocks are used optimally.

Quality was a factor that is critical it comes down down to blocks that are forged. Manufacturers always promise they follow industry criteria and regulations when making the blocks. They even create certification and testing services to guarantee that the blocks meet the quality requirements that are highest.

Application of Forged Blocks:

Forged blocks have a range this is certainly wide of in different industries. They are used in manufacturing, construction, gas and oil, and industries that are automotive. They are used as support structures, machinery components, tools, and equipment. They are also used in construction and bridge that is building.

Forged blocks are critical components in various industries. The forged block production process involves heating and materials that are shaping create durable and high-strength blocks. The blocks offer various advantages, like durability, precision, and opposition. It's important to select blocks that meet industry instructions and requirements to promise their utilize that is optimal and. Manufacturers provide various services to customers, like consultation, repair, and assessment. This really is industries that are certainly vital are various with their many applications, forged blocks play a role.

No comments yet