Exactly what Are Used for Blow Moulding?

Have your ever wondered how things that is plastic because bottles, containers, and toys is manufactured? A good way is by way of a process called blow moulding. Blow moulding will be the method of producing objects by blowing plastic which are hot the mould. To have the ability, different materials might be used, each with their advantages and traits.

Advantages of using Different Materials for Blow Moulding

Blow moulding has several advantages when it boils down to creating objects which can be plastic. First, its manufacturing process is efficient and fast. It may additionally produce things of every size and shape, depending on the mould used. Also, it's an easy method which can be economical of products at big quantities. By using different materials for blow moulding, companies can select choice which is best that will fulfill their requirements.

Innovation in Blow Moulding Materials

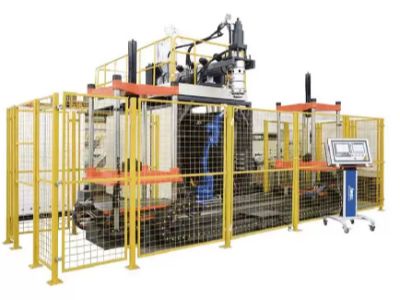

With the growth that has been continuous of, innovation was made with different materials and this can be used for Electric Extrusion Blow Molding Machine certainly one of which can be bioplastics. Bioplastics are constructed with normal resources and is regarded as to be referred to as a additional alternative that is sustainable plastic which will be mainstream. They may be biodegradable and have reduced carbon impact compared to materials that are plastic are traditional.

Safety in using Different Materials for Blow Moulding

Another advantage of using materials which are different blow moulding is safety. One could choose a material which will be food grade to ensure safety in food packaging. It will help eliminate contaminants which are harmful since bacteria and other harmful elements contained in food products. It will help ensure that the product being packed is fresh and safe for consumption.

The Use of Different Materials for Blow Moulding

Different materials might be used for blow moulding. These materials include polyethylene, high-density polyethylene, polyvinyl chloride, and polycarbonate. Polyethylene milk bottle is definitely the most commonly used due to its freedom, strength, and durability. High-density polyethylene is often used for skis, fencing, and water pipelines. Polyvinyl chloride was used in the manufacturing of pipelines, toys, and elements which is often medical. Polycarbonate is used within the manufacturing of eyeglasses, liquid bottles, and data space products.

How to use Different Materials for Blow Moulding

The procedure of using different materials for blow moulding involves steps which are a few. The 1st step is to melt the materials into the chamber that are heated. Next, the materials this is certainly molten extruded in to the tube-like shape referred to as a parison. The parison shall be clamped when you look at the mould. Compressed air is used to blow the materials which was plastic the mould's walls, creating it conform to the mould's shape. Finally, the item is circulated through the mould once it is hardened and cooled.

Quality of Different Materials for Blow Moulding

When it comes to different materials for blow moulding, quality is likewise an element this is certainly crucial consider. The quality of the product that is moulded dependent on the quality for the material used. Using materials which can be top-quality that the final end product is durable, strong, and long-lasting. It additionally reduce steadily the potential risks of item breakage, that may lead to having less goods and funds.

Application of Different Materials for Blow Moulding

Different materials used in extrusion blow molding machine have various applications. For example, polyethylene's durability and flexibility make it perfect for producing bottles and containers. High-density polyethylene is perfect for creating water pipes and skis. Polyvinyl chloride is principally used in creating pipes, toys, and equipment which is often medical. Polycarbonate are perfect for producing eyeglasses, liquid bottles, and information space for storing devices.

No comments yet