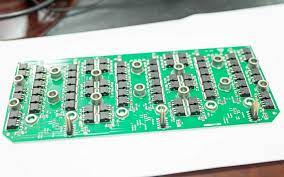

Aluminum PCBs (Printed Circuit Boards) are a popular option for high-power LED lighting, automotive applications, and other electronic devices that require efficient heat dissipation. In order to produce high-quality aluminum PCBs, the etching process is essential. However, the etching process can also pose challenges, including the risk of acid traps. In this article, we will discuss the etching process for aluminum PCBs and how to avoid acid traps to ensure reliable and efficient performance.

Aluminum PCB Etching Process:

The etching process for aluminum PCBs is similar to the process for standard PCBs, with a few key differences. The process typically involves the following steps:

- Cleaning and preparation: The aluminum substrate is cleaned and prepared for the etching process. This includes removing any contaminants or oxide layers on the surface.

- Etching: The aluminum substrate is coated with a layer of resist material, which is then patterned using a photolithography process. The exposed areas are then etched using an etchant solution, which removes the aluminum from the substrate and leaves behind the desired circuit pattern.

- Stripping: The remaining resist material is stripped away using a chemical solution, leaving behind the final aluminum PCB.

The etching process is crucial to the success of the aluminum PCB, as it determines the final circuit pattern and quality. However, the process can also pose challenges, including the risk of acid traps.

What is an Acid Trap?

An acid trap is a pocket of etchant solution that becomes trapped in a small area of the PCB during the etching process. This can occur when the etchant solution is unable to flow freely through the patterned resist material, and instead becomes trapped in a small crevice or corner. When the etchant solution is not properly removed from the PCB, it can continue to corrode the aluminum substrate, causing damage to the circuit pattern and reducing the overall quality and reliability of the PCB.

How to Avoid Acid Traps:

To avoid acid traps during the PCB etching process, there are several steps that can be taken:

- Use proper design rules: Designing the PCB with proper design rules can help to minimize the risk of acid traps. This includes avoiding sharp corners and small crevices in the circuit pattern, and ensuring that the resist material is patterned in a way that allows for proper etchant flow.

- Use the right etchant solution: The type and concentration of etchant solution used can also impact the risk of acid traps. Using a high-quality etchant solution with the right concentration can help to ensure proper etching and reduce the risk of acid traps.

- Optimize the etching process: Optimizing the etching process can also help to reduce the risk of acid traps. This includes ensuring that the etchant solution is properly agitated and circulated during the etching process and that the PCB is rinsed thoroughly after etching to remove any remaining etchant solution.

Conclusion:

Aluminum PCBs are a popular option for electronic devices that require efficient heat dissipation, and the etching process is essential to their production. However, the etching process can also pose challenges, including the risk of acid traps. By understanding the etching process for aluminum PCBs and taking steps to avoid acid traps, engineers can ensure that their aluminum PCBs meet the highest standards of quality and reliability. Proper design rules, high-quality etchant solutions, and optimized etching processes can all contribute to successful aluminum PCB production.

No comments yet