Carbide rods are taking the manufacturing industry by storm, redefining sustainability. These innovative tools pave the way for more environmentally conscious and efficient manufacturing processes. Carbide rods have become a game-changer for industries worldwide with their exceptional durability, versatility, and eco-friendly properties. In this article, we'll explore how carbide rods reshape the manufacturing landscape and promote a greener future.

Unleashing the Power of Carbide Rods

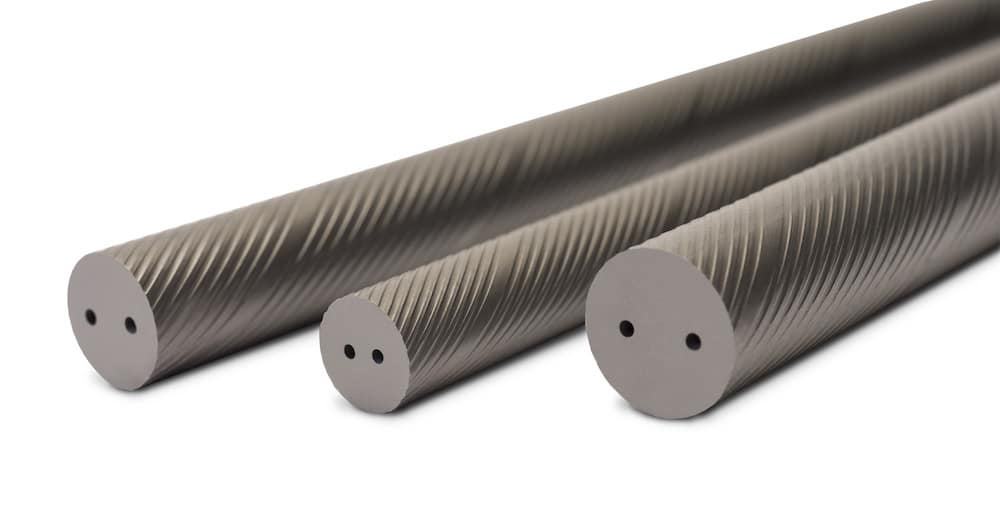

Carbide rods are engineered to withstand high temperatures, extreme pressures, and intense wear and tear. This exceptional resilience makes them ideal for various manufacturing applications, from cutting and drilling to milling and shaping. Their incredible strength and durability significantly enhance productivity and longevity, reducing the need for frequent replacements and minimizing material waste.

The Eco-Friendly Advantage

One of the most remarkable aspects of carbide rods is their eco-friendly nature. These rods predominantly comprise tungsten carbide, a compound known for its sustainability and low environmental impact. Unlike traditional manufacturing materials, such as high-speed steel, carbide rods have a significantly longer lifespan and require fewer resources for production.

Reducing Material Waste

Carbide rods' exceptional hardness and resistance to wear ensure minimal material waste during manufacturing. Unlike conventional tools that quickly become dull and ineffective, carbide rods retain their sharpness and cutting efficiency for extended periods. This longevity translates to reduced material waste and a more sustainable approach to manufacturing.

Energy Efficiency at Its Best

Another significant advantage of carbide rods is their energy efficiency. With their exceptional heat resistance and ability to maintain cutting precision, these rods enable manufacturers to optimize their energy consumption. Carbide rods contribute to lower energy costs and a greener manufacturing ecosystem by reducing the need for excessive heat and repeated machining.

Versatility Unleashed

Carbide rods offer unparalleled versatility, allowing manufacturers to easily tackle a diverse range of applications. These rods are revolutionizing manufacturing processes across various sectors, from the aerospace and automotive industries to construction and electronics. Their ability to withstand extreme conditions and deliver consistent results makes them an indispensable tool in the modern industrial landscape.

Embracing Sustainability in Manufacturing

In today's world, sustainability is a top priority for businesses across industries. Carbide rods empower manufacturers to embrace sustainability without compromising performance or quality. By incorporating these rods into their processes, manufacturers can reduce their environmental footprint, conserve resources, and achieve higher efficiency.

The Future of Manufacturing

As the demand for greener and more sustainable manufacturing practices continues to rise, carbide rods are poised to play a pivotal role in shaping the industry's future. With their unrivaled strength, longevity, and eco-friendly properties, these rods redefine manufacturing norms and promote a more sustainable and responsible approach.

No comments yet