In the realm of modern materials, High-Density Polyethylene (HDPE) sheets stand as a testament to innovation and utility. These durable, versatile sheets find applications across a wide range of industries, from construction and manufacturing to agriculture and beyond. In this comprehensive guide, we will delve into the world of HDPE sheets, exploring their composition, properties, diverse applications, and the myriad benefits they offer to various sectors. HDPE sheet manufacturers are continually pushing the boundaries of what these remarkable materials can achieve, offering customized solutions to meet the specific needs of their customers.

Understanding HDPE Sheets

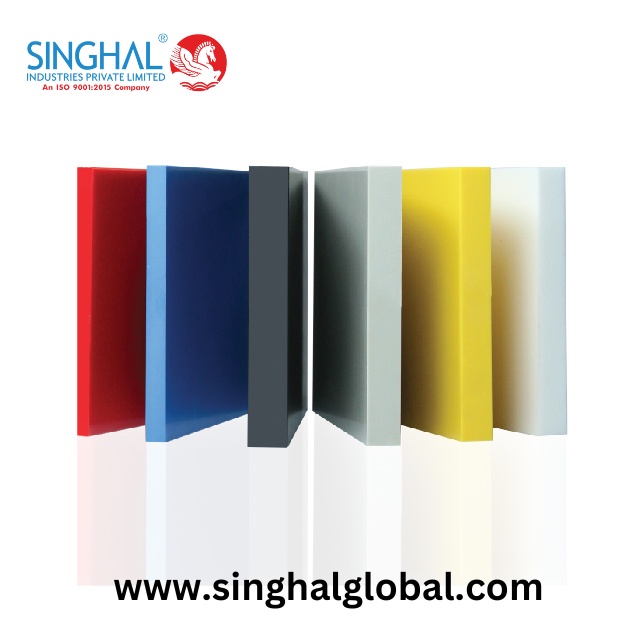

HDPE sheets are flat panels manufactured from high-density polyethylene resin, a type of thermoplastic polymer renowned for its exceptional strength, durability, and chemical resistance. These sheets are produced through a process of extrusion, which involves melting the HDPE resin and then shaping it into flat sheets of varying thicknesses. HDPE sheets come in a range of sizes, colors, and surface textures to suit different applications and requirements.

HDPE sheet manufacturer employ advanced technologies and stringent quality control measures to ensure that their products meet the highest standards of performance and reliability. With their expertise and dedication to innovation, these manufacturers continue to push the boundaries of what HDPE sheets can achieve, opening up new possibilities for industries ranging from construction and agriculture to packaging and beyond.

Properties and Characteristics

HDPE sheets boast a plethora of desirable properties that make them ideal for numerous applications. Some key characteristics include:

-

Strength and Durability: HDPE sheets exhibit high tensile strength and excellent resistance to impact, making them suitable for demanding environments where toughness is paramount.

-

Chemical Resistance: HDPE is highly resistant to chemicals, acids, and alkalis, making it suitable for use in corrosive environments such as chemical processing plants and laboratories.

-

UV Resistance: HDPE sheets have inherent UV resistance, allowing them to withstand prolonged exposure to sunlight without degrading or losing their structural integrity.

-

Flexibility: Despite their robustness, HDPE sheets remain flexible and easy to manipulate, allowing for easy fabrication and installation in various applications.

Applications of HDPE Sheets

The versatility of HDPE sheets lends them to a wide array of applications across different industries:

-

Construction: HDPE sheets are commonly used in the construction industry for applications such as wall cladding, roofing, and waterproofing membranes. Their durability and weather resistance make them ideal for outdoor construction projects.

-

Agriculture: In agriculture, HDPE sheets find use in applications such as greenhouse construction, pond liners, and agricultural drainage systems. Their chemical resistance and impermeability make them well-suited for these applications.

-

Manufacturing: HDPE sheets are utilized in the manufacturing sector for fabricating a range of products, including tanks, containers, and machine parts. Their machinability and resistance to abrasion make them ideal for these purposes.

-

Packaging: HDPE sheets are also used in packaging applications, such as manufacturing plastic crates, pallets, and bins. Their strength and durability ensure the safe transportation and storage of goods.

Benefits of HDPE Sheets

The use of HDPE sheets offers several benefits across various industries:

-

Cost-Effectiveness: HDPE sheets are relatively inexpensive compared to other materials, offering cost-effective solutions for a wide range of applications.

-

Longevity: HDPE sheets are durable and resistant to environmental factors such as moisture, chemicals, and UV radiation, ensuring a long service life with minimal maintenance requirements.

-

Sustainability: HDPE is a recyclable material, making HDPE sheets an environmentally friendly option. Additionally, their longevity reduces the need for frequent replacements, further reducing environmental impact.

-

Versatility: With their wide range of properties and applications, HDPE sheets provide versatility and flexibility in meeting diverse project requirements.

Conclusion

In conclusion, HDPE sheets stand as versatile, durable, and cost-effective materials with applications spanning multiple industries. Their strength, durability, and resistance to environmental factors make them invaluable assets in construction, agriculture, manufacturing, and packaging. By understanding the properties, applications, and benefits of HDPE sheets, businesses, and industries can leverage their capabilities to achieve optimal results in various projects and applications. HDPE sheet manufacturers in india continue to play a crucial role in ensuring the availability of high-quality materials to meet the diverse needs of their customers. With a commitment to excellence and customer satisfaction, these suppliers contribute to the continued success and innovation in industries relying on HDPE sheets.

Frequently Asked Questions (FAQs):

-

FAQ: Are HDPE sheets suitable for outdoor applications?

Answer: Yes, HDPE sheets are highly resistant to weathering, UV radiation, and moisture, making them ideal for outdoor use in various industries such as construction, agriculture, and signage. -

FAQ: Can HDPE sheets be recycled?

Answer: Absolutely! HDPE is a thermoplastic polymer that is widely recyclable. Singhal Industries ensures that our HDPE sheets are manufactured with recyclability in mind, contributing to a more sustainable production cycle. -

FAQ: What sizes and thicknesses are available for HDPE sheets from Singhal Industries?

Answer: Singhal Industries offers a wide range of sizes and thickness options for HDPE sheets to cater to diverse customer needs. Whether you require thin sheets for packaging or thicker sheets for structural applications, we have you covered.

No comments yet