High-density polyethylene sheets have emerged as a versatile and valuable material across various industries. Their unique combination of strength, durability, and cost-effectiveness makes them a prime choice for a wide range of applications. This article delves into the potential of HDPE sheets, exploring their properties, benefits, and innovative uses that address contemporary challenges.

Understanding HDPE Sheets:

Manufactured from polyethylene polymers with a high density, HDPE sheets offer exceptional strength and rigidity. They are known for their:

1. High tensile strength: Best hdpe sheets can withstand significant pulling forces without breaking or deforming.

2. Impact resistance: They exhibit excellent resistance to impact, making them suitable for demanding applications.

3. Chemical resistance: HDPE sheets are largely unaffected by many chemicals, acids, and bases, ensuring longevity.

4. Weather resistance: They are resistant to UV rays, moisture, and extreme temperatures, ideal for outdoor applications.

5. Lightweight: Despite their strength, HDPE sheets are surprisingly lightweight, simplifying transportation and installation.

6. Cost-effective: Compared to traditional materials like metal or wood, HDPE sheets offer a cost-efficient solution.

7. Recyclability: HDPE is a recyclable material, contributing to environmental sustainability.

Benefits of Utilizing HDPE Sheets:

The aforementioned properties translate into a plethora of benefits for various applications. Here's a glimpse into some key advantages:

1. Durability: HDPE sheets offer exceptional longevity, withstanding harsh environments and demanding use for extended periods.

2. Versatility: Their adaptability allows them to be fabricated into diverse shapes and sizes, catering to specific project requirements.

3. Low maintenance: HDPE sheets require minimal maintenance due to their inherent resistance to corrosion and chemicals.

4. Safety: They are non-toxic and non-corrosive, making them safe for use in various settings, including contact with food and beverages.

5. Sustainability: The recyclability of HDPE sheets minimizes environmental impact and promotes resource conservation.

Innovative Applications of HDPE Sheets:

HDPE sheets are revolutionizing various industries by offering innovative solutions to address contemporary challenges. Here are some prominent examples:

1. Construction: HDPE sheets are employed for:

a) Concrete curing blankets: They aid in retaining moisture and regulating concrete curing temperature, leading to improved strength and crack resistance.

b) Vapor barriers: HDPE sheets act as effective vapor barriers in building envelopes, preventing moisture intrusion and promoting energy efficiency.

c) Formwork: Reusable HDPE formwork systems offer a lightweight, durable, and cost-effective alternative to traditional wood or metal for concrete molding.

2. Chemical and Industrial Applications: HDPE sheets find use in:

a) Chemical containment: Their chemical resistance makes them ideal for lining tanks, ponds, and secondary containment structures to prevent leaks and spills.

b) Industrial flooring: HDPE sheets provide a robust, chemical-resistant, and easy-to-clean flooring solution for industrial environments.

c) Machinery components: Due to their wear resistance, HDPE sheets can be fabricated into gears, sprockets, and other machine components.

3. Environmental Solutions: HDPE sheets contribute to environmental sustainability through:

a) Erosion control: They are used to create erosion control mats and silt fences, preventing soil erosion and protecting waterways.

b) Spill containment: HDPE's chemical resistance makes it suitable for spill containment berms and secondary containment structures.

c) Waste management: HDPE liners are employed in landfills and waste containment applications to prevent environmental contamination.

4. Other Applications: The versatility of HDPE sheets extends to:

a) Signage and displays: Their lightweight nature and printability make them ideal for creating durable and cost-effective signs and displays.

b) Marine applications: HDPE's buoyancy and resistance to saltwater corrosion make it suitable for boat docks, buoys, and marine equipment.

c) Medical applications: HDPE sheets are used for sterilization trays, medical equipment components, and other applications due to their biocompatibility and ease of sterilization.

Finding the Right Polyethylene Sheet Manufacturers and Suppliers:

When selecting HDPE sheets, partnering with reliable Polyethylene sheet manufacturers and suppliers is crucial. Here are some key factors to consider:

1. Reputation: Choose a supplier with a proven track record of delivering high-quality HDPE sheets.

2. Product variety: Ensure the supplier offers a variety of HDPE sheet thicknesses, sizes, and grades to meet your specific needs.

3. Customization options: Look for suppliers who can customize sheets based on your size, thickness, and color requirements.

4. Technical expertise: A knowledgeable supplier can provide valuable guidance on selecting the most appropriate HDPE sheet for your application.

Conclusion:

HDPE sheets represent a powerful and versatile material shaping the future across various industries. Their exceptional properties, coupled with their cost-effectiveness and recyclability, make them a sustainable and responsible choice. As technology advancements continue, we can expect even more innovative applications of HDPE sheets to emerge. From infrastructure development to environmental solutions, HDPE sheets hold immense potential for creating a more sustainable and resilient future.

FAQs (Frequently asked questions)

Q1. What are the different thicknesses available for HDPE sheets?

A1. HDPE sheets come in a variety of thicknesses, typically ranging from a fraction of a millimeter to several centimeters. The specific thickness chosen depends on the intended application.

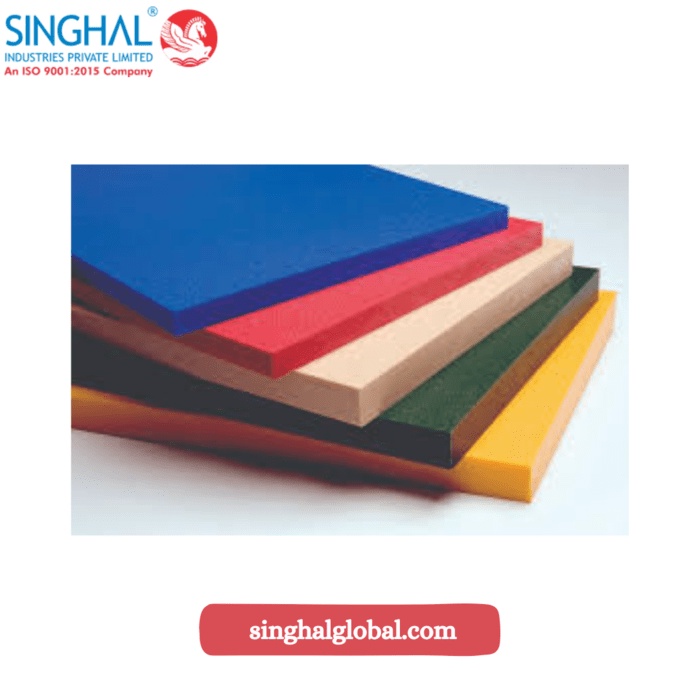

Q2. Can HDPE sheets be colored?

A2. Yes, HDPE sheets can be pigmented during manufacturing to achieve various colors. This can enhance aesthetics or improve visibility for specific applications.

Q3. How are HDPE sheets joined together?

A3. HDPE sheets can be joined using various techniques, including heat welding, solvent welding, and mechanical fasteners. The chosen method depends on the desired strength and application requirements.

No comments yet