In the world of plastics, High-Density Polyethylene (HDPE) stands out as a versatile and widely used material. Among its various forms, HDPE sheets have gained prominence due to their exceptional properties and diverse applications. In this comprehensive guide, we'll delve into the realm of HDPE sheets, exploring their composition, benefits, applications across industries, and environmental considerations. HDPE sheet manufacturers play a crucial role in providing quality sheets that meet the diverse needs of industries and contribute to sustainable solutions.

Understanding HDPE Sheets

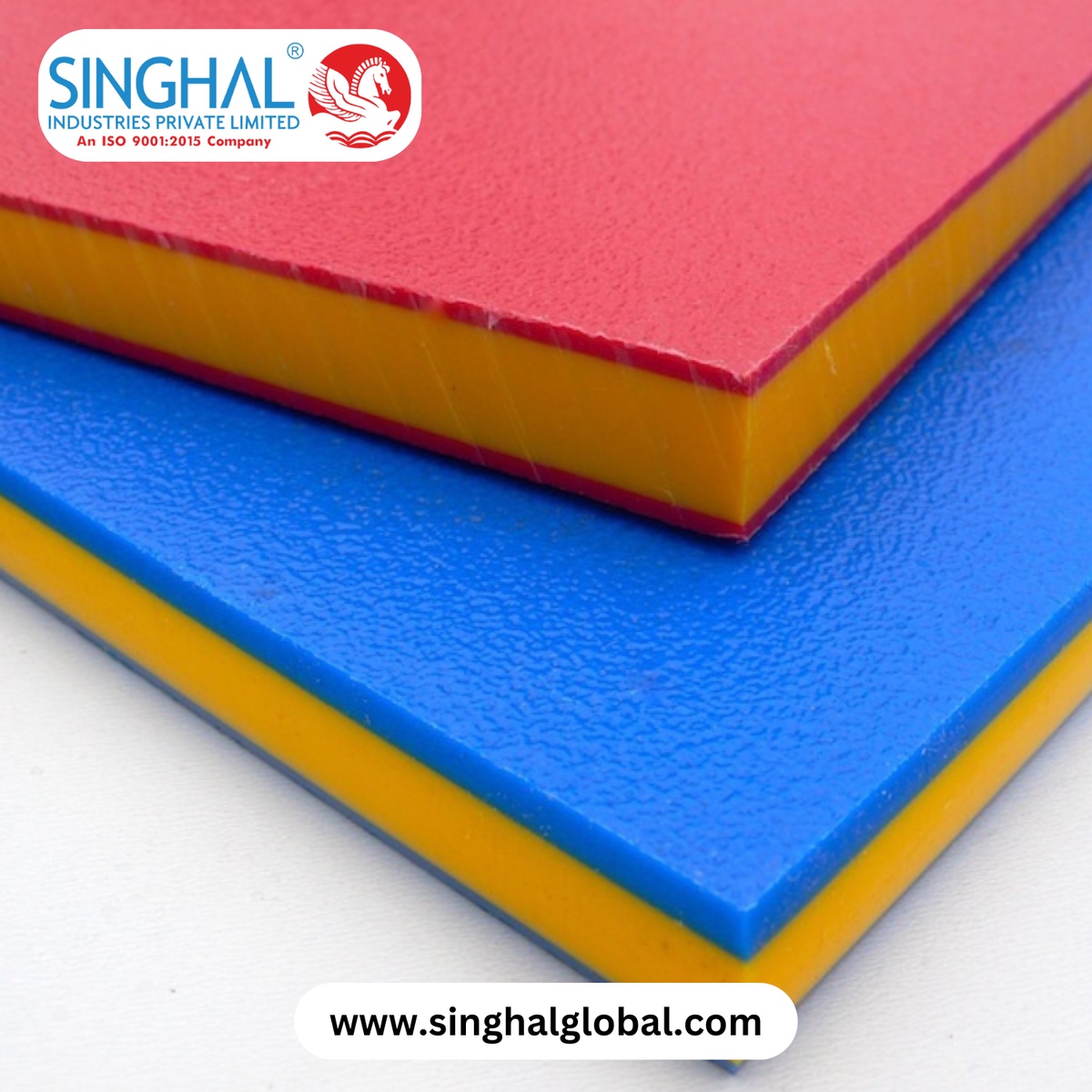

HDPE sheets are flat plastic sheets manufactured from high-density polyethylene resin. The production process involves extruding molten HDPE resin through a die to form a continuous sheet, which is then cooled and cut into specific sizes and thicknesses. These sheets are renowned for their high strength-to-density ratio, chemical resistance, and durability, making them suitable for a wide range of applications. HDPE sheet manufacturer play a pivotal role in ensuring the quality and availability of these versatile sheets for various industries.

Benefits of HDPE Sheets:

- Durability: HDPE sheets exhibit excellent durability, with resistance to corrosion, abrasion, and impact. They can withstand harsh environmental conditions, making them ideal for outdoor applications.

- Chemical Resistance: HDPE sheets are chemically inert and resistant to a wide range of chemicals, acids, and alkalis, making them suitable for use in chemical processing and storage industries.

- Versatility: HDPE sheets are available in various sizes, thicknesses, and colors, offering versatility in design and application. They can be easily fabricated, machined, welded, and thermoformed to meet specific requirements.

- Lightweight: Despite their robustness, HDPE sheets are lightweight, allowing for easy handling, transportation, and installation.

- Recyclability: HDPE is a highly recyclable material, contributing to sustainability efforts and environmental conservation.

Applications of HDPE Sheets:

- Construction: HDPE sheets find widespread use in the construction industry for applications such as protective barriers, wall cladding, roofing membranes, and formwork.

- Packaging: HDPE sheets are utilized in packaging applications for manufacturing crates, pallets, containers, and storage bins due to their strength and impact resistance.

- Agriculture: In agriculture, HDPE sheets are used for lining ponds, reservoirs, and irrigation channels, as well as in greenhouse construction and livestock housing.

- Transportation: HDPE sheets are employed in the transportation sector for manufacturing truck bed liners, cargo containers, and vehicle interior components due to their durability and impact resistance.

- Marine: HDPE sheets are used in marine applications for constructing boat components, dock fenders, and seawalls, thanks to their resistance to saltwater corrosion.

Environmental Considerations:

While HDPE sheets offer numerous benefits, it's essential to consider their environmental impact. HDPE is a recyclable material, and recycling programs exist to reclaim and repurpose used HDPE products. Additionally, HDPE sheets can contribute to sustainability efforts by reducing the need for frequent replacements, thus conserving resources and minimizing waste.

Conclusion

HDPE sheets are versatile, durable, and sustainable materials that find applications across various industries. With their exceptional properties, including durability, chemical resistance, and recyclability, HDPE sheets offer cost-effective solutions for a wide range of applications. Whether in construction, packaging, agriculture, transportation, or marine sectors, HDPE sheets continue to play a vital role in shaping modern industries while contributing to environmental sustainability. As technology advances and sustainability becomes increasingly important, the versatility and utility of HDPE sheets are expected to continue expanding, driving innovation and meeting evolving market demands. HDPE sheet manufacturers in India are at the forefront of this industry, providing high-quality products that cater to the diverse needs of the Indian market and beyond.

Frequently Asked Questions (FAQs):

-

FAQ: How does Singhal Industries ensure the quality of its HDPE sheets?

Answer: At Singhal Industries, quality is our top priority. We employ stringent quality control measures throughout the manufacturing process of our HDPE sheets, from raw material sourcing to final product inspection. Our state-of-the-art facilities and experienced team ensure that every sheet meets industry standards for durability, chemical resistance, and dimensional accuracy.

-

FAQ: Can Singhal Industries customize HDPE sheets to specific dimensions or colors?

Answer: Yes, Singhal Industries offers customization options for HDPE sheets to meet the unique requirements of our customers. Whether it's a specific size, thickness, or color preference, our skilled technicians can tailor HDPE sheets to match your project specifications. Contact our sales team to discuss your customization needs.

-

FAQ: Are Singhal Industries' HDPE sheets environmentally friendly?

Answer: Yes, Singhal Industries is committed to sustainability. Our HDPE sheets are recyclable, contributing to environmental conservation efforts. Additionally, our manufacturing processes adhere to eco-friendly practices to minimize waste and energy consumption. Choose Singhal Industries for high-quality HDPE sheets that prioritize both performance and environmental responsibility.

No comments yet