In the packaging industry, ensuring the integrity and durability of boxes is essential to protect products during storage, transportation, and handling. A box compression tester is a vital tool used to evaluate the compressive strength of corrugated boxes and ensure they can withstand the rigours of the supply chain. In this blog post, we will explore the importance of box compression testers and their significance in the packaging industry.

What is a Box Compression Tester?

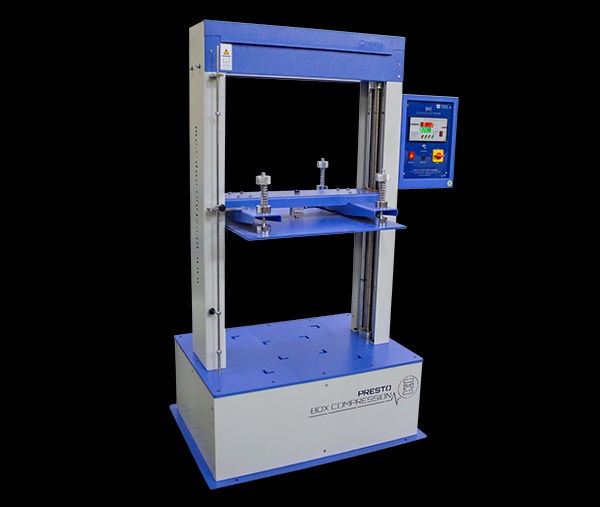

A box compression tester is a mechanical device designed to measure the compressive strength of corrugated boxes by subjecting them to controlled vertical pressure. By simulating the forces exerted on boxes during stacking and handling, the tester helps manufacturers assess their structural integrity and determine their load-bearing capacity.

How Does it Work?

During testing, a corrugated box is placed on the compression platen of the tester, and a hydraulic or pneumatic ram applies vertical pressure until the box collapses or reaches a predetermined compression level. The maximum force sustained by the box before failure is recorded as its compression strength, which indicates its ability to withstand stacking and handling forces.

Ensuring Product Protection

The primary role of a box compression tester is to ensure that packaging materials can adequately protect products from damage during transit and storage. By accurately assessing the compressive strength of boxes, manufacturers can identify potential weaknesses and make informed decisions to improve packaging designs and materials.

Preventing Product Losses

Weak or improperly designed boxes are prone to collapsing under pressure, leading to product damage, loss, and costly returns. By implementing box compression testing as part of their quality control processes, manufacturers can minimize the risk of product losses and maintain customer satisfaction.

Meeting Regulatory Requirements

Many industries have regulations and standards governing packaging specifications, including minimum compression strength requirements. Compliance with these standards is essential for ensuring product safety and meeting customer expectations. A box compression tester helps manufacturers demonstrate compliance with regulatory requirements and avoid potential penalties or legal liabilities.

Food and Beverage

In the food and beverage industry, ensuring the integrity of packaging is crucial to prevent contamination and spoilage of perishable goods. Box compression testers are used to evaluate the strength of corrugated boxes used for packaging food products and beverages, ensuring they can withstand the weight of stacked containers without collapsing.

Conclusion

In conclusion, box compression testers are indispensable tools in the packaging industry for evaluating the strength and durability of corrugated boxes. By accurately assessing the compressive strength of boxes, manufacturers can ensure product protection, prevent losses, meet regulatory requirements, and enhance customer satisfaction. From food and beverage packaging to e-commerce and retail shipments, the importance of box compression testing cannot be overstated in maintaining the integrity of packaging materials and safeguarding products throughout the supply chain.

No comments yet