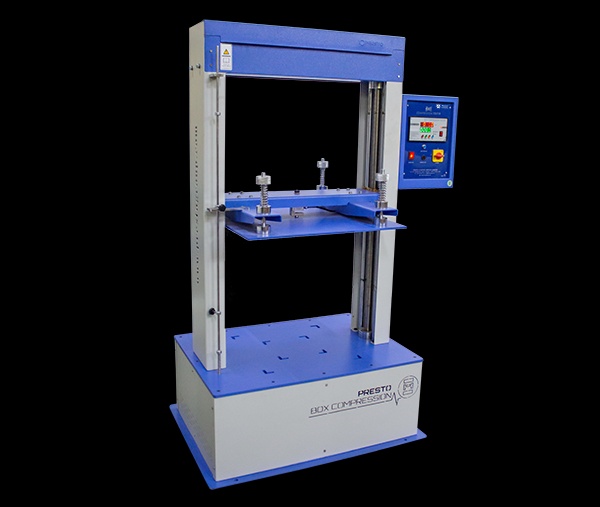

The box compression tester is a specialised instrument designed to evaluate the compressive strength of corrugated boxes and cartons, adhering to international standards. Box Compression strength, or the ability of a material to withstand forces that tend to reduce its size, is a critical parameter in assessing the durability and integrity of packaging materials.

What is a compression tester used for?

Compression testers serve the purpose of subjecting materials to crushing loads, providing insights into their behaviour under pressure. Typically, these tests involve applying compressive force to a test specimen, often in the form of a cuboid or cylindrical shape, using platens or custom fixtures on a universal testing machine.

How do you calculate the box compression test?

BCT = 5.876*ECT*SQRT(P*T).

- BCT is the Box Crush Test (BCT)

- ECT is the edge crush test (ECT)

- P is the box perimeter (in)

- T is the box thickness (in)

- SQRT is the square root.

The calculation of box compression strength (BCT) involves a formula incorporating parameters such as edge crush test (ECT), box perimeter (P), and box thickness (T). By utilising this formula, one can determine the BCT value of materials, ensuring the delivery of high-quality products to customers and reducing rejection rates.

What are the three types of compression tests?

The different compression test standards change depending on the material type or sample geometry you are testing. These differences affect your test fixture choices, software calculations, and data analysis. Using our Newton controller, each test report can contain different data from one test sample to the next.

The advantages of employing a box compression tester in packaging are manifold. Firstly, it aids in quality assurance by accurately assessing the compressive strength of packaging materials, thereby minimising the risk of product damage during storage and transportation. Additionally, it enables manufacturers to optimise packaging designs, leading to cost savings and enhanced efficiency in the supply chain.

The common compression tests include:

- Materials strength and characterization

- Top-load/Crush Testing

- ECT (Edge crush tests)

- Compression spring testing

- Product Tests of components & assemblies

As for the types of Box compression tests, they vary depending on factors such as material type and sample geometry. Common compression test standards encompass assessments of material strength, top-load or crush testing, ECT, and compression spring testing, among others. With the flexibility offered by modern testing equipment, each test report can be tailored to provide specific data relevant to the sample being evaluated.

No comments yet