In the realm of packaging materials, ensuring quality and durability is paramount. Manufacturers and consumers alike rely on rigorous testing procedures to guarantee that packaging meets industry standards. One such crucial test is the Box compression Test (BCT), a fundamental assessment that evaluates the strength and resilience of packaging materials. Let's delve into the intricacies of the BCT test procedure and its significance in the packaging industry.

What is the BCT Test?

The Box Compression Test (BCT) is a standardised procedure designed to measure the maximum pressure or force that a material can withstand before rupturing . It is particularly relevant for assessing the strength of corrugated and paperboard materials commonly used in packaging applications.

Importance of BCT Testing in Packaging

- Ensuring Product Integrity: By determining the packaging materials, manufacturers can ensure that products remain intact and protected during handling, transit, and storage.

- Compliance with Industry Standards: Adhering to Box compression testing protocols ensures that packaging materials meet regulatory requirements and industry standards for quality and safety.

- Preventing Damages and Losses: Packaging failures due to inadequate strength can lead to product damages, financial losses, and reputational damage. Box compression testing helps mitigate such risks by identifying potential weaknesses in packaging materials.

- Optimising Packaging Design: Insights from Box compression testing enable manufacturers to optimise packaging design and material selection, leading to more efficient and cost-effective solutions.

The Box compression Test Procedure

- Sample Preparation: The testing process begins with preparing representative samples of the packaging material to be evaluated. These samples are typically cut into standardised shapes and sizes to ensure consistency.

- Mounting the Sample: The prepared sample is securely mounted onto the testing apparatus, ensuring that it is evenly aligned and free from any wrinkles or folds that could affect the test results.

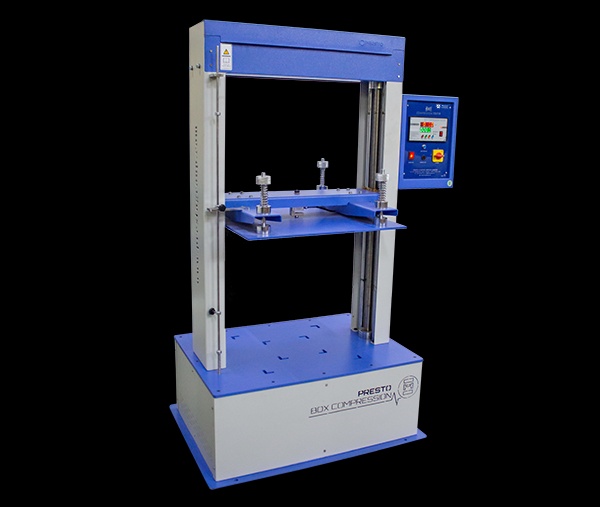

- Application of Pressure: A hydraulic or pneumatic system is used to apply pressure gradually to the sample until it ruptures. The pressure is measured in pounds per square inch (psi) or kilopascals (kPa).

Conclusion: Enhancing Packaging Quality with Box compression Testing

In conclusion, the Box compression test (BCT) is a vital component of quality assurance in the packaging industry. By subjecting materials to rigorous testing procedures, manufacturers can ensure that their packaging solutions meet the demands of modern supply chains and provide adequate protection to goods. As consumer expectations continue to evolve, investing in Box compression testing remains essential for maintaining competitiveness and fostering trust in product integrity.

No comments yet