In the world of agriculture and food production, advancements in technology and machinery continue to play a pivotal role in enhancing efficiency and quality. One such innovation that has transformed rice processing is the use of Rice Dehusking Rubber Rolls. These unassuming components have revolutionized the way we remove the tough outer husk from rice grains, making the process not only faster but also more cost-effective and environmentally friendly.

Rice is a staple food for billions of people around the globe, and its journey from the paddy fields to our plates involves several crucial steps. One of the most critical stages in rice processing is the removal of the husk, which protects the edible grain inside. Traditionally, this was done using abrasive stones or manual labor, both of which were time-consuming and often resulted in a lower-quality product.

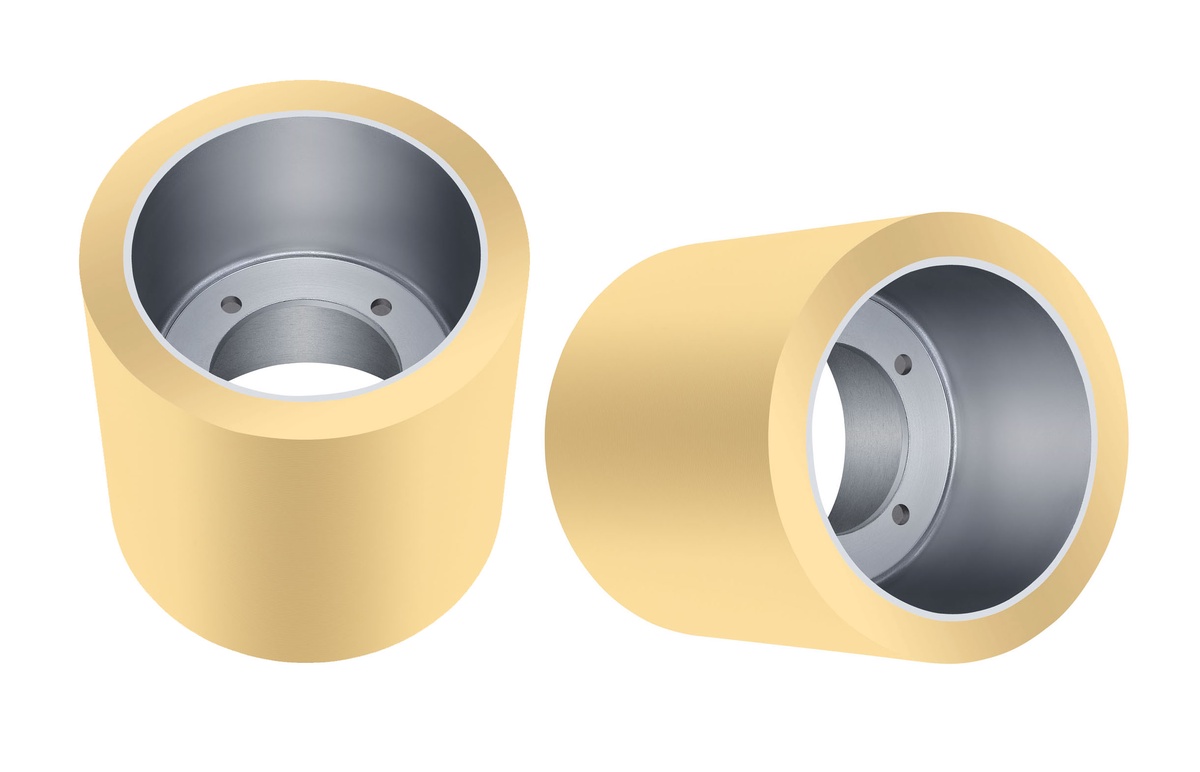

Enter Rice Dehusking Rubber Rolls, a game-changer in the rice milling industry. These rolls, made from high-quality rubber compounds, are designed to mimic the abrasive action of traditional stones but with far greater precision and efficiency. Here's how they work:

Rubber vs. Stone: Unlike traditional stones that can wear down and require frequent replacement, rubber rolls are durable and have a longer lifespan. This durability translates to cost savings for rice mill owners and ultimately benefits consumers through lower rice prices.

Uniform Dehusking: Rubber rolls provide a consistent and uniform dehusking action, ensuring that each rice grain is processed to the same high standard. This uniformity in dehusking not only improves the quality of the rice but also reduces waste.

Lower Energy Consumption: Rice Dehusking Rubber Rolls are more energy-efficient compared to stone dehusking methods. This means reduced energy costs and a smaller carbon footprint, making rice processing more environmentally friendly.

Easy Maintenance: Maintenance of rubber rolls is simpler and less labor-intensive than traditional stone dehusking equipment. This leads to reduced downtime and increased operational efficiency.

Customization: Rubber rolls can be tailored to specific rice varieties and processing needs, further optimizing the quality and yield of rice production.

The adoption of Rice Dehusking Rubber Rolls has not only improved the efficiency of rice processing but has also contributed to the overall quality of the end product. Consumers benefit from better-tasting rice with fewer broken grains, while rice mill owners enjoy cost savings and increased productivity.

In conclusion, the evolution of rice processing technology, as exemplified by Rice Dehusking Rubber Rolls, highlights the profound impact that innovation can have on the food industry. As we continue to seek ways to feed a growing global population while minimizing waste and environmental impact, advancements like these represent a significant step forward. So, the next time you enjoy a plate of perfectly cooked rice, you can appreciate the science and technology that went into producing it.

No comments yet