Edge banding is a widely used technique in woodworking to cover and protect the exposed edges of wood panels. To achieve a professional and finished look, the excess edge banding material needs to be trimmed accurately. This is where an edge banding trimmer comes into play.

We will explore the purpose and benefits of an edge banding trimmer, its features, and how it simplifies the edge banding process.

Understanding the Edge Banding Trimmer

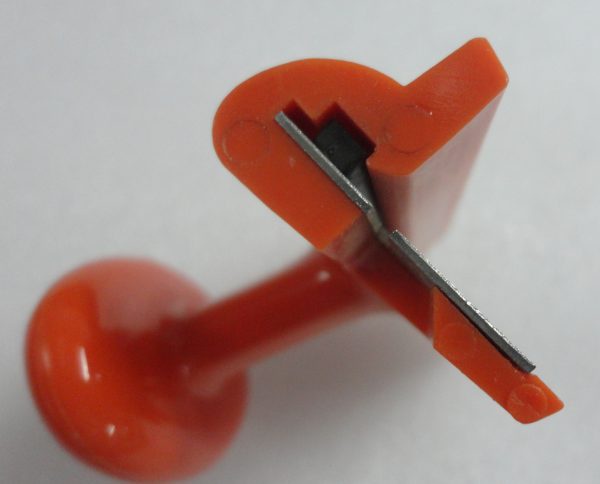

An edge banding trimmer, also known as an edge trimmer or edge cutter, is a specialized tool designed to remove the excess edge banding material after it has been applied to wood panels. It trims the banding flush with the panel's surface, resulting in clean and precise edges.

Purpose and Benefits

The primary purpose of an edge banding trimmer is to provide a seamless and professional finish to woodworking projects. Here are the key benefits it offers:

- a) Precise Trimming: An edge banding trimmer is equipped with sharp blades that are specifically designed to trim the excess banding material accurately. This ensures clean and straight edges, eliminating any unevenness or protrusions.

- b) Time and Labor Efficiency: Trimming edge banding manually using a utility knife or other tools can be time-consuming and labor-intensive. An edge banding trimmer streamlines the trimming process, allowing for faster and more efficient completion of woodworking projects.

- c) Consistency: The use of an edge banding trimmer ensures consistent and uniform trimming throughout the project. This results in a professional and cohesive appearance, especially when dealing with multiple panels or large-scale woodworking operations.

- d) Safety: Edge banding trimmers are designed with safety features to protect the user's hands during operation. They typically have ergonomic handles and guards to prevent accidental injuries while trimming the banding.

Features and Functionality

Edge banding trimmer come in various designs and models, but they generally share some common features:

- a) Adjustable Depth: Many trimmers offer adjustable depth settings, allowing the user to control how much material is trimmed. This feature ensures flexibility and precision, especially when dealing with different thicknesses of edge banding.

- b) Replaceable Blades: The blades of an edge banding trimmer may need replacement over time due to wear and tear. Most trimmers have replaceable blades, making maintenance and longevity of the tool convenient and cost-effective.

- c) Ergonomic Design: Edge banding trimmers are typically designed with ergonomic handles for comfortable grip and control. This allows the user to maneuver the tool with ease, enhancing accuracy and reducing fatigue during prolonged use.

- d) Compatibility: Edge banding trimmers are compatible with various types of edge banding materials, including wood veneer, PVC, ABS, and melamine. They can effectively trim these materials without causing damage or leaving rough edges.

Conclusion

An edge banding trimmer is an invaluable tool for achieving a professional and seamless finish in woodworking projects. With its precise trimming capabilities, time efficiency, and consistent results, the trimmer simplifies the edge banding process and enhances the overall aesthetics of the project. By investing in an edge banding trimmer and following proper usage and safety guidelines, woodworkers can achieve clean and flawless edges, elevating the quality and appeal of their woodworking creations.

No comments yet