Using an edge banding trimmer is a skill that can significantly enhance your woodworking projects. Whether you're a seasoned professional or a DIY enthusiast, mastering the use of this tool is essential for achieving clean, precise, and professional-looking edges.

Proper Alignment Is Key

One of the fundamental aspects of using an edge banding trimmer effectively is proper alignment. Before you begin trimming, ensure that the trimmer is aligned correctly with the edge of the wood. Misalignment can result in uneven or jagged edges, which can detract from the overall quality of your project.

Tip: Use clamps or guides to help maintain proper alignment while trimming. This will ensure that the trimmer follows a straight path along the edge.

Choose the Right Edge Banding Trimmer

Selecting the appropriate edge banding trimmer for your project is crucial. Different types of trimmers are available, including manual, electric, and pneumatic models. Consider the following factors when choosing the right trimmer:

- Project Size:

- For small-scale projects, a manual edge banding trimmer may suffice, offering precise control.

- Electric edge banding trimmers are suitable for medium-sized projects and provide efficient trimming.

- Pneumatic edge banding trimmers are ideal for large-scale or industrial applications, offering speed and power.

- Material Compatibility:

Ensure that the selected trimmer is compatible with the type of edge banding material you plan to use. Trimers should work effectively with various materials, including wood veneer, PVC, and ABS.

Tip: If you frequently work on projects of different sizes and materials, having a selection of trimmers can be advantageous.

Regular Maintenance Matters

Like any tool, an edge banding trimmer requires regular maintenance to perform at its best. Keep the following maintenance tips in mind:

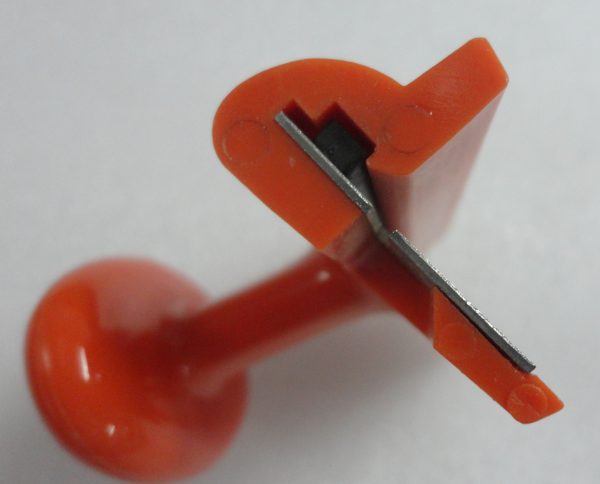

- Blade or Cutting Wheel:

The blade or cutting wheel of the trimmer should be kept sharp. Dull blades can result in tearing or uneven edges. Regularly inspect and sharpen or replace the cutting element as needed.

- Lubrication:

Some trimmers may require lubrication to ensure smooth operation. Check the manufacturer's recommendations for the specific trimmer you are using and follow their guidelines for lubrication.

- Cleanliness:

Keep the trimmer clean and free from debris. Dust and adhesive residue can accumulate over time and affect the tool's performance. Cleaning the trimmer after each use is a good practice.

Tip: Consider creating a maintenance schedule to ensure that your edge banding trimmer remains in optimal condition.

Practice Makes Perfect

Using an edge banding trimmer effectively requires practice. Begin with smaller, less critical projects to hone your skills before tackling larger or more complex tasks. Familiarize yourself with the trimmer's operation, including the pressure required and the speed at which it should be moved along the edge.

Tip: Keep scrap pieces of edge banding material and practice trimming on these pieces to refine your technique.

Exercise Caution and Safety

Safety should always be a priority when using any woodworking tool, including edge banding trimmers. Some safety precautions to keep in mind include:

- Eye Protection: Wear safety goggles or glasses to protect your eyes from flying debris.

- Hand Protection: Consider wearing gloves to protect your hands from sharp edges and potential splinters.

- Ear Protection: Electric and pneumatic trimmers can produce noise, so ear protection may be necessary.

To be conclude

Understanding the art of using an edge banding trimmer effectively is a valuable skill for any woodworker. Proper alignment, choosing the right trimmer, regular maintenance, practice, and safety precautions are all essential elements of successful edge banding. By following these tips and techniques, you can achieve clean, precise, and professional edges in your woodworking projects.

No comments yet