A fluidized IQF freezer freezes products individually to prevent the formation of lumps or blocks. This reduces dehydration, helps maintain texture and quality, and increases the shelf life of the frozen product.

Several elements contribute to the right fluidization in the IQF freezer, including fans, the bedplate, and the overall design. Processors must be careful not to overlook these elements.

Pre-freezing

The process of pre-freezing involves reducing the temperature below the freezing point to the extent that part of the water content changes from liquid to solid. This change in state is called nucleation and results in the formation of ice crystals.

This technique is used for a wide range of products, including fruit, vegetables, berries, poultry, seafood and meat. It is also used to freeze brittle products or those that have a tendency to stick together.

A common method of pre-freezing is immersion, where the product is immersed in liquid nitrogen at low temperatures and is frozen rapidly while being moved to prevent block or lump formation. This method is effective but may require higher processing costs per weight of product because the cost of liquid nitrogen is high.

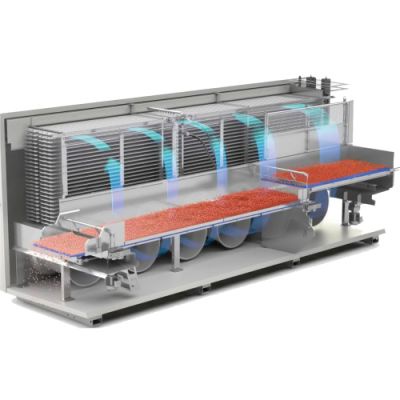

A more gentle and efficient way of pre-freezing is fluidization, where the product is completely lifted from the bedplate using cold airstreams in a series of stages. There are two main types of fluidization--circulating and bubbling--and they are usually used in the first part of the IQF Freezer tunnel.

image source https://www.pinterest.ph/

Freeze-drying

Freeze-drying is a process that removes water from a material by sublimation (sublimation is the transition of water from solid to vapor, which then omits the liquid state). It is used to dry many different food and biological materials.

The process requires control of the freezing rate, temperature level, total gas pressure, and final mean moisture content to obtain a freeze-dried product with adequate quality [84]. This is done by ensuring that the heat supply does not exceed the melt point for the frozen products, which can lead to material degradation.

The freeze-drying process is divided into the primary and secondary drying phases. During the primary drying phase, the water vapor pressure is lowered and the temperature is decreased. During the secondary drying phase, the temperature is increased to encourage desorption of the remaining water molecules that are still in the product. This is a very slow stage of the Vacuum Freeze Drying Equipment process and may take at least 30% longer than the end of the primary drying phase.

Packing

A fludized iqf freezer is used for a wide variety of products, from frozen shrimp to hamburger patties. It utilizes impingement freezing, which directs high-speed airstreams from above and below the product. The process achieves freezing in a few minutes, allowing frozen foods to be prepared for consumption without defrosting or thawing.

IQF freezers also incorporate a unique technology called fluidization, which freezes each of the tiny particles that make up the food item in question. This process turns the particles into a liquid in an upward airflow, resulting in a fast freeze and no ice crystal formation.

Fluidization is one of the most important parts of the Fluidized IQF Freezer, and it comes in 3 main types: circulating fluidization, bubbling fluidization and fixed bed fluidization. Each type is used in a different part of the freezer. Using the right fluidization will help frozen food processors get the best-looking, most separated product that will hold up to cold temperatures for long periods of time.

image source https://www.pinterest.ph/

Storage

IQF freezers are used for freezing small-sized products such as peas, corn, berries and fruits. This type of freezing prevents the formation of large ice crystals in the food product and preserves their structural integrity.

Unlike cold storage freezers, IQF Vacuum Freeze Dryer do not require boxes or trays for storing products. The IQF technique freezes all the individual pieces of food items separately from each other, which helps in maintaining their shape and preserving their shelf life for a long period.

Fluidization is an important element of IQF technology that allows for the fast freezing of small-sized food items, thereby reducing dehydration and maintaining their texture and nutrients. There are 3 main types of fluidizations used in IQF machines – circulating fluidization, bubbling fluidization and fixed bed fluidization.

The right fluidization is necessary for achieving optimal freezing results and maximizing the quality of the frozen product. This is achieved by adjusting the fans, the bedplate and the overall design of the freezer body.

No comments yet