In the dynamic landscape of business, innovation and cost-effectiveness are two pillars that determine success. Whether it's a startup embarking on a new product journey or an established company seeking to optimize its offerings, the ability to innovate while minimizing costs is paramount. This is where the strategic application of prototyping comes into play. In this article, we explore how CNC Prototyping, a sophisticated technology that seamlessly integrates creativity and precision, offers businesses in the Bay Area cost-effective solutions that accelerate growth.

Understanding CNC Prototyping

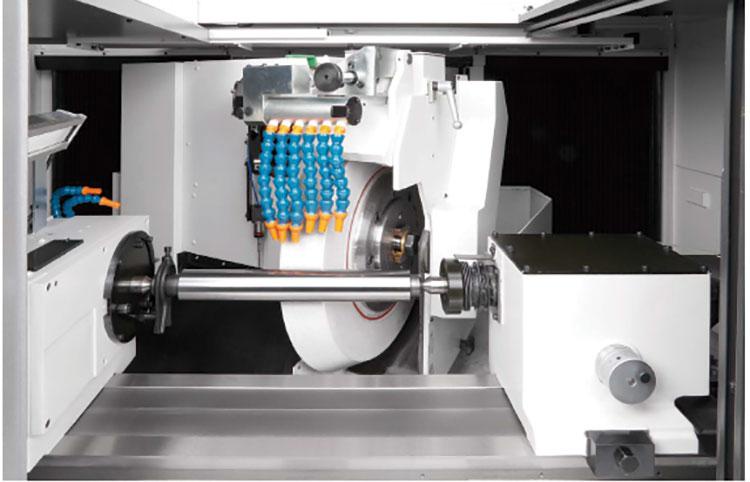

In the realm of product development, where ideas transform into tangible realities, CNC Prototyping stands as a pivotal tool. CNC, or Computer Numerical Control, Prototyping involves the utilization of computer-controlled machinery to craft prototypes with exceptional precision and accuracy. This process yields functional prototypes that enable businesses to test concepts, refine designs, and identify potential issues early in the development cycle.

Accelerated Product Development

In a landscape where innovation races against time, rapid product development is essential. CNC Prototyping takes center stage by expediting the journey from concept to reality. By swiftly transforming digital designs into physical prototypes, businesses can assess the feasibility of ideas and make informed decisions. This acceleration not only shortens development cycles but also enhances a company's agility in responding to market demands.

Cost-Efficiency Through Iteration

Innovation thrives on iteration—the process of refining and enhancing designs based on feedback. This iterative approach is where CNC Prototyping shines in terms of cost-effectiveness. The ability to swiftly iterate designs minimizes the expenditure associated with multiple trial-and-error cycles. Businesses can make adjustments, assess performance, and fine-tune prototypes without incurring significant costs.

Minimizing Production Risks

Transitioning directly to full-scale production can be a risky endeavor, with potential pitfalls awaiting discovery at the production stage. CNC Prototyping acts as a sentinel, identifying design flaws and discrepancies early in the process. By addressing issues during the prototyping phase, businesses mitigate the risk of expensive production errors, saving both time and resources.

Customization and Adaptability

Consumer preferences are evolving towards personalized experiences, and businesses must adapt to this trend. CNC Prototyping's inherent flexibility makes it an ideal solution for crafting customized products. The technology accommodates intricate design variations, enabling businesses to tailor products to individual customer needs. This versatility empowers companies to cater to niche markets and stand out in a competitive landscape.

Collaborative Innovation

CNC Prototyping thrives in collaborative environments, fostering cross-functional innovation. During the prototyping phase, diverse teams—ranging from designers and engineers to marketing and production—can converge to contribute their insights. This collaborative effort leads to holistic improvements, as collective expertise converges to refine the product and align it with customer expectations.

CNC Prototyping emerges as a transformative force, uniting innovation and cost-effectiveness in the business realm. Through its rapidity, precision, and iterative potential, businesses in the Bay Area can leverage CNC Prototyping to streamline product development and reduce costs. Its dynamic capabilities, coupled with its ability to identify issues early on, empower companies to thrive in a fast-paced market. As you navigate the intricate landscape of product development, consider its strategic advantages. If you're seeking a partner that embodies technology and expertise, explore the services offered by Alpha Precision CNC to embark on a journey of cost-effective innovation.

No comments yet